Electronic commerce product logistics sending and packaging auxiliary system

An e-commerce and auxiliary system technology, applied in packaging, transportation and packaging, labeling, etc., can solve the unfavorable comparison efficiency of glue packaging and printing stamps, affect the inflow of packages, increase the non-processing time of parcel glue packaging and printing stamp marks and other problems, to achieve the effect of improving the working efficiency of gluing, reducing non-processing time, and reducing non-processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

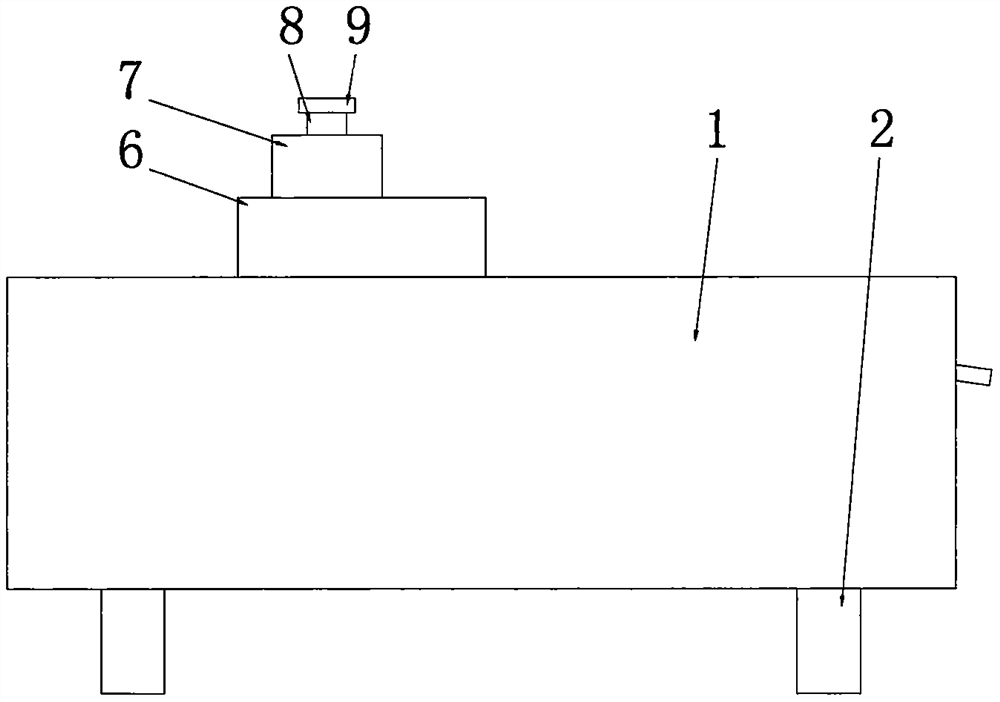

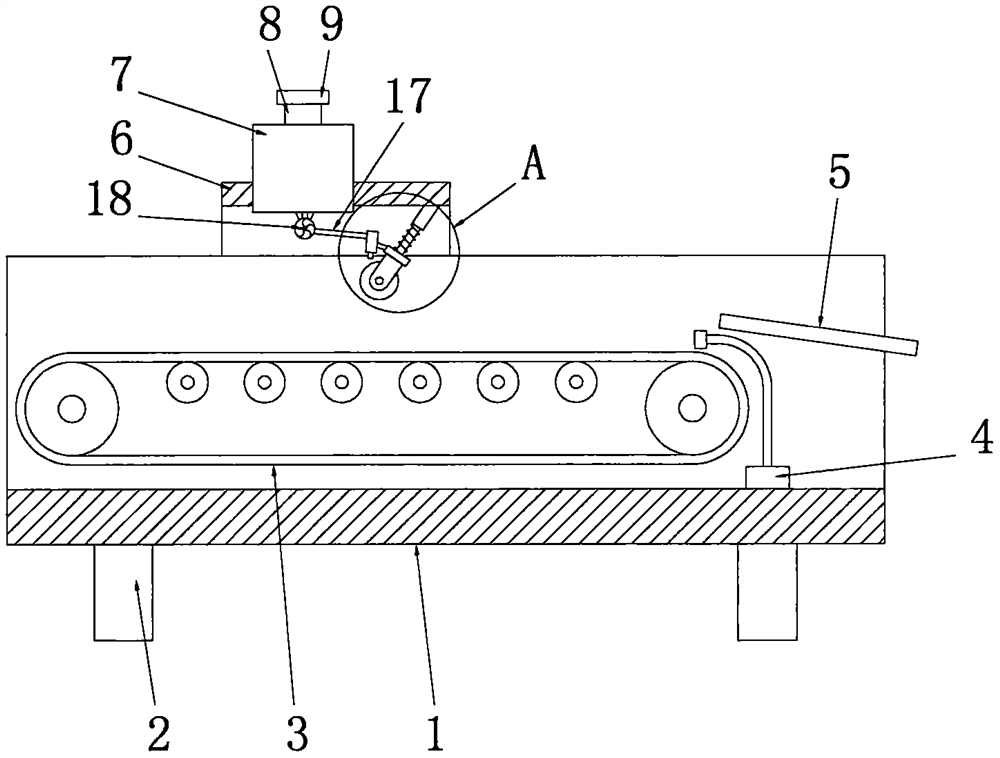

[0030] See Figure 1-3 , an auxiliary system for sending and packaging e-commerce products, comprising a frame 1, the frame 1 is a U-shaped structure, the bottom of the frame 1 is uniformly provided with a plurality of legs 2, and the inner cavity of the frame 1 is provided with Transmission mechanism 3, the right side of the bottom wall of the inner cavity of the frame 1 is provided with a stamp mechanism 4 that matches the transmission mechanism 3, and the inner cavity of the frame 1 is provided with a discharge plate that cooperates with the transmission mechanism 3 and the stamp mechanism 4 respectively 5. The discharge plate 5 is set obliquely, and the package on the transmission mechanism 3 moves with the transmission mechanism 3, and then the bottom of the side end of the package close to the stamp mechanism 4 collides with the stamp mechanism 4 to complete the printing mark work, and the package Under the action of the seal mechanism 4, it rolls onto the discharge plat...

Embodiment 2

[0034] See Figure 4 The difference from Embodiment 1 is that the conveying mechanism 3 includes two conveying rollers 31 and several supporting rollers 34, and the two conveying rollers 31 are arranged on the left and right sides of the inner cavity of the frame 1, and the conveying rollers 31 pass through The transmission shaft 32 is rotatably connected on the frame 1, and the two transmission rollers 31 are connected by a transmission belt 33. One end of the transmission shaft 32 penetrates the side wall of the frame 1 and is rotatably connected to an external motor (not shown in the figure). , all the supporting rollers 34 are arranged side by side in parallel with the inner cavity of the conveyor belt 33, the supporting rollers 34 are connected to the frame 1 through the rotation of the rotating shaft 35, and the external motor cooperates with the transmitting shaft 32 to drive the transmitting roller 31 to rotate, and then utilize the transmitting roller 31 drives the co...

Embodiment 3

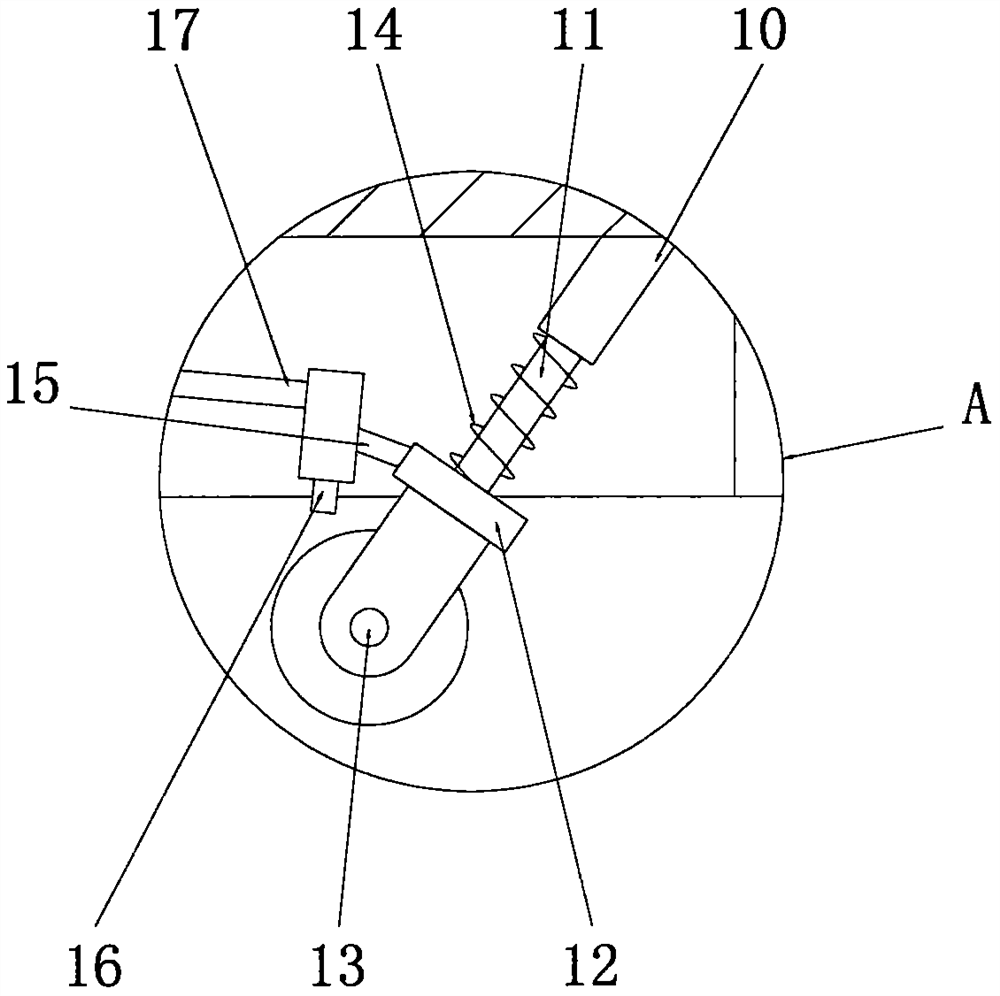

[0036] See Figure 5 The difference from Embodiment 1 is that the stamp mechanism 4 includes a medicine box 401, the medicine box 401 is fixedly connected to the bottom wall of the inner chamber of the frame 1, and the top side of the medicine box 401 is fixedly connected to the standpipe 402, The standpipe 402 is an L-shaped structure, and one end of the standpipe 402 away from the medicine box 401 is fixedly connected to a stabilizing bar 403, and the end of the stabilizing bar 403 away from the standpipe 402 is fixedly connected with a stamp body 404 matched with the conveyor belt 33, so The stamp body 404 is 8mm-10mm higher than the top surface of the conveyor belt 33, and the end of the stamp body 404 away from the stabilizing bar 403 is provided with a printing end 405, and the stabilizing bar 403 is provided with a medicine seepage chamber 407, and the medicine seepage chamber 407 passes through A number of drug seepage tubes 406 are connected to the printing end 405. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com