Small thin-wall shell batch production tooling

A thin-walled shell and tooling production technology, which is applied in the field of mechanical processing, can solve the problems of large processing volume, poor material process performance, and easy deformation, etc., and achieve the effect of improving processing efficiency and saving non-processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

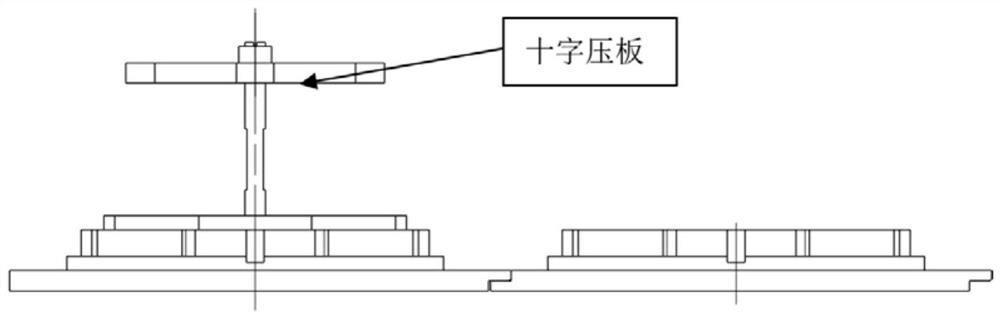

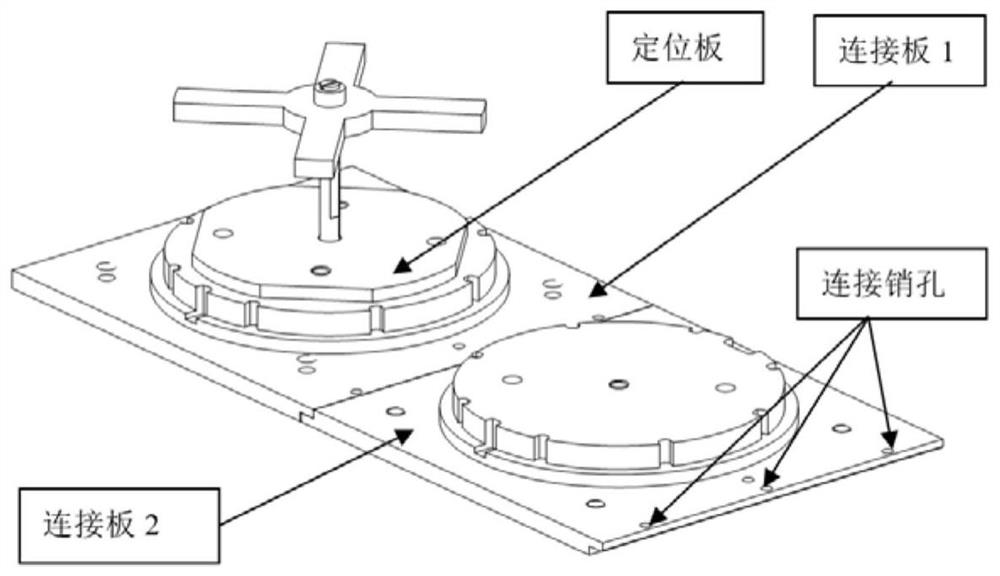

[0016] refer to figure 1 and figure 2 As shown, the tooling for mass production of small thin-walled shells of the present invention includes a plurality of tooling units spliced in sequence, and each tooling unit includes a connecting plate and a positioning plate; a boss is arranged on the connecting plate to match the notch of the part; The connecting plate is used for positioning the inner cavity of the thin-walled shell; splicing steps are set on both sides of the connecting plate. shape structure.

[0017] A supporting column is arranged in the center of the positioning plate, and a cross pressing plate is installed on the supporting column, and the cross pressing plate performs positioning and pressing on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com