Multifunctional workpiece holder

A workpiece fixture and multi-functional technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of low work efficiency, single function of the workpiece chuck, inconvenience of repeated work, etc., to achieve convenient operation, improve work efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

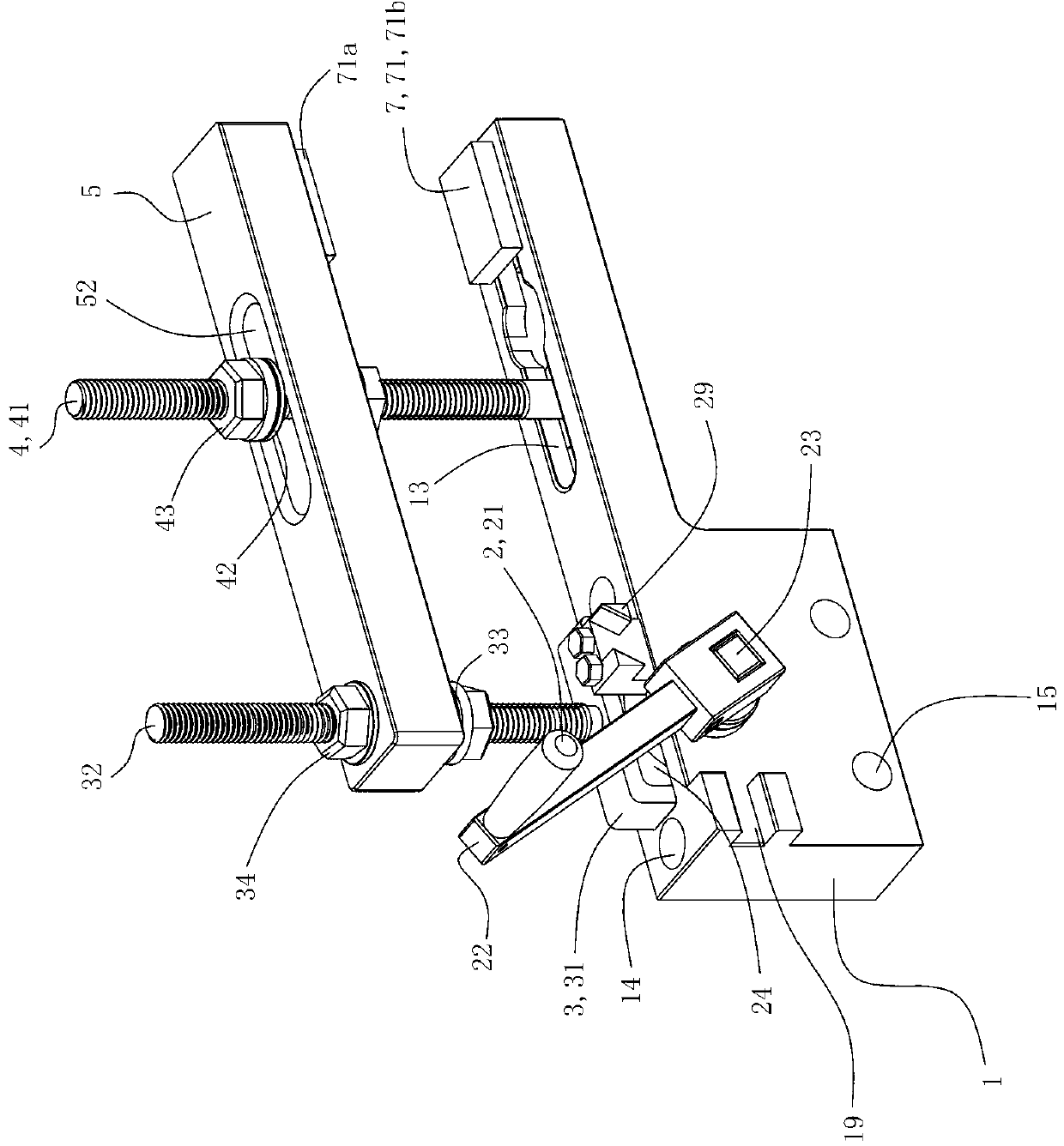

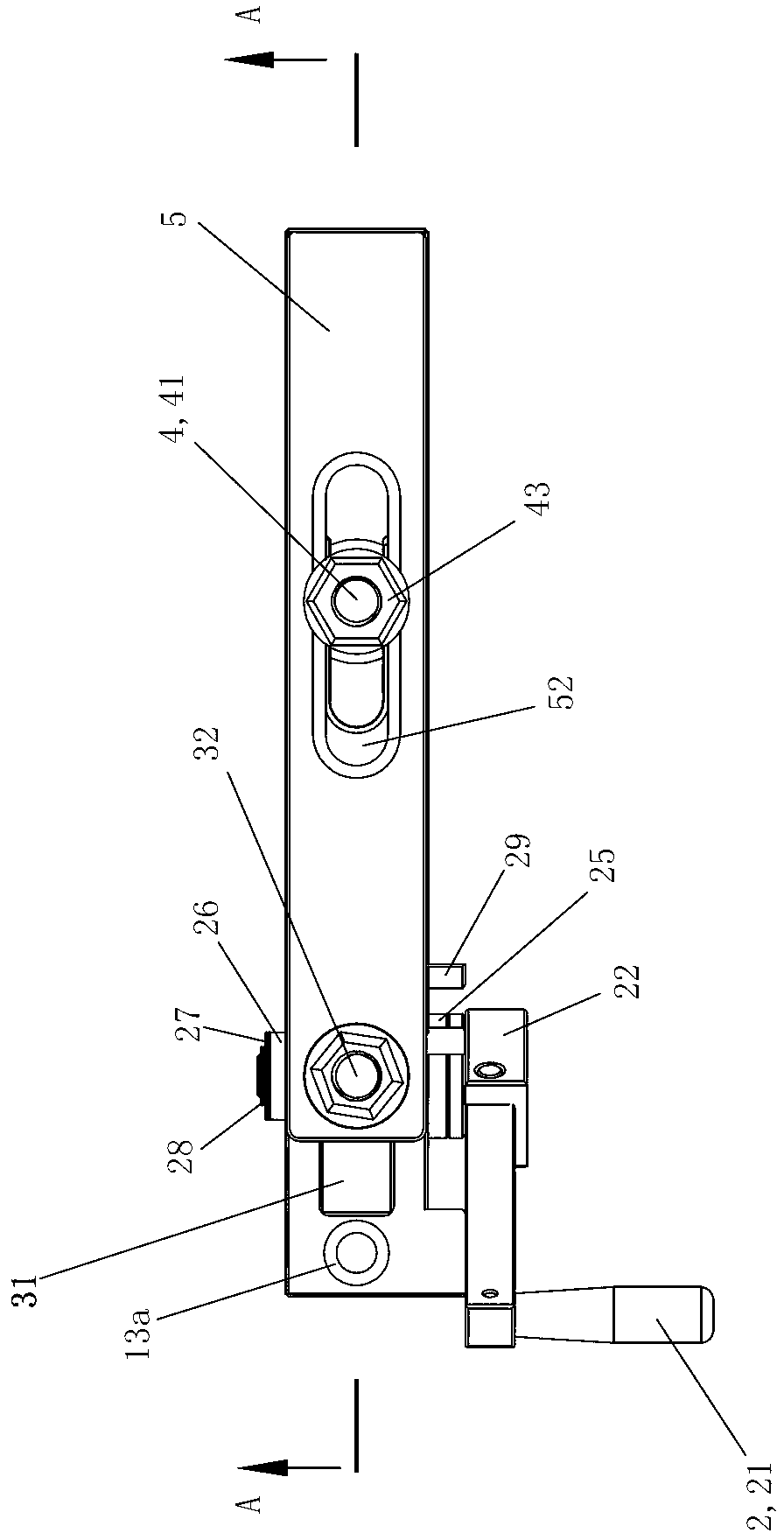

[0069] See figure 1 and Figure 5 , The multifunctional workpiece fixture of this embodiment includes a base 1 , a manipulation assembly 2 , a frame rod assembly 3 , a support rod assembly 4 , a pressure plate 5 , a reset assembly 6 and a pressure head assembly 7 .

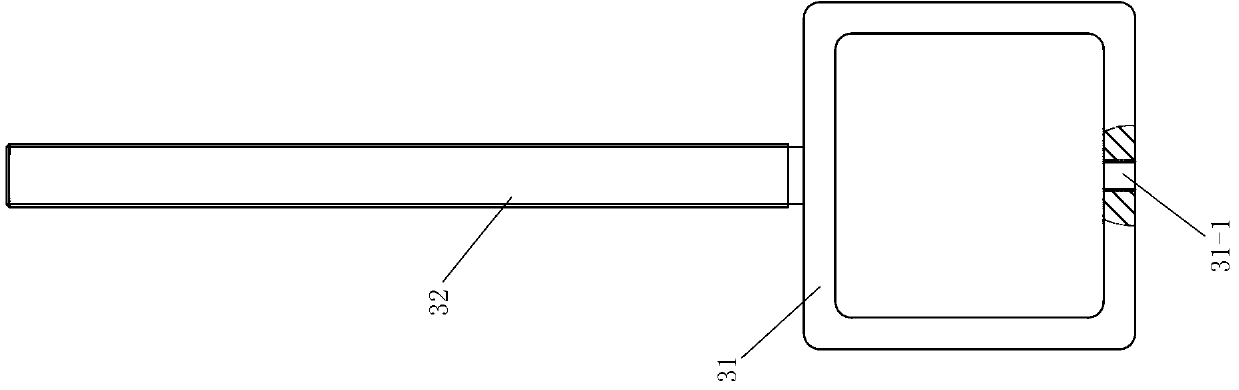

[0070] See Figure 5 , Figure 7 Figure 10 and Figure 11, The base 1 is an integral piece made of steel. The left part of the base 1 is provided with a square mounting hole 11 with an upward opening. The left part of the base 1 is also provided with two front and rear rotating shaft installation holes 12 with axes arranged along the front and rear directions and communicating with the square installation hole 11. The two rotating shaft installation holes 12 are divided into front and rear sides according to their front and rear positions. Mounting hole 12-1 and rear side mounting hole 12-2. The front mounting hole 12-1 and the rear mounting hole 12-2 are coaxial, and the diameter of the rear mounting hole...

Embodiment 2)

[0085] The rest of this embodiment is the same as that of Embodiment 1, except that the nut 34 of the frame rod assembly 3 in this embodiment is a spherical shoulder nut, so the frame rod assembly 3 of this embodiment does not have a spherical washer 33 . The nut 43 of the support rod assembly 4 is a spherical shoulder nut, so the support rod assembly 4 of this embodiment does not have a spherical washer 42 .

Embodiment 3)

[0087] See Figure 20 , the rest of this embodiment is the same as that of Embodiment 1, except that the reset assembly 6 further includes an end cap 63 . The reset bolt 61 passes through the adjustment hole 17 of the base 1 from bottom to top, and then is screwed into the screw hole 31 - 1 of the transmission frame 31 of the frame rod assembly 3 by the corresponding part of its threaded part. The compression spring 62 is arranged on the underside of the end of the reset bolt 61 , and the end cap 63 is screwed into the adjustment hole 17 of the base 1 to press the compression spring 62 on the lower end of the reset bolt 61 from bottom to top. Turn the pressing plate 5 upwards by 180 degrees, so that its T-shaped slot 53 is located on the upper side of the right end.

[0088] When the present invention is used as a clamping workpiece state, move the handle 21 upwards to make the rocker arm member 22 rotate clockwise 60 degrees with the rotating shaft 23 as the rotating shaft; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chamfer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com