Corrugated cardboard printing machine and its automatic shutdown control system for paper feeding failure

A corrugated cardboard and control system technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of automatic shutdown, paper jam alarm not in time, alarm, etc., to improve work efficiency, facilitate operation, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

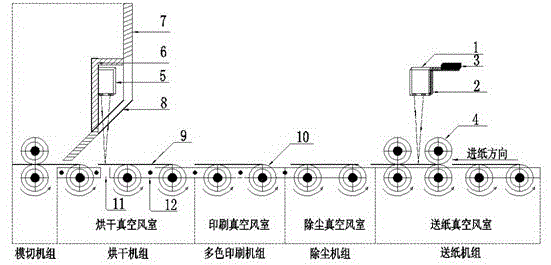

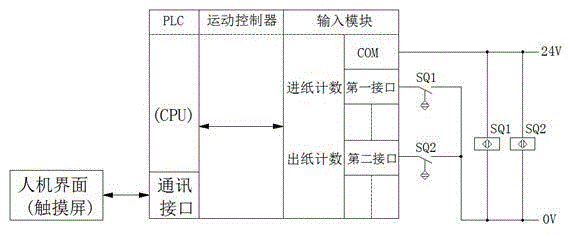

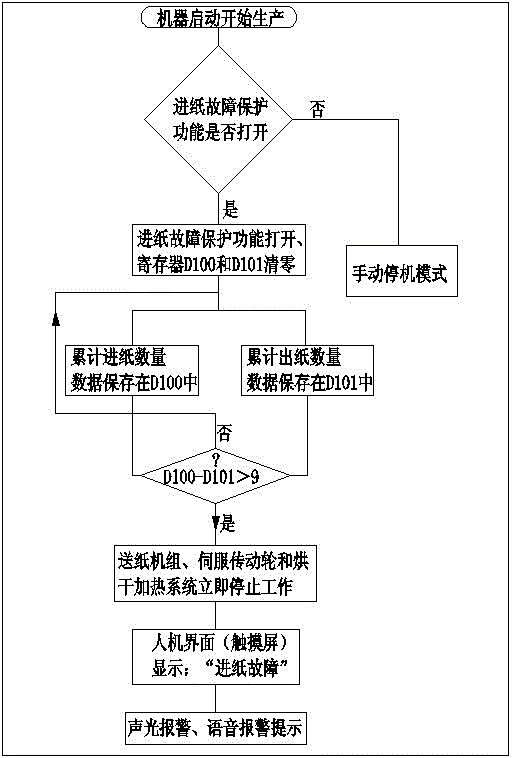

[0034] A corrugated cardboard printing machine paper feeding failure automatic shutdown control system, such as figure 1 as shown,

[0035] The corrugated cardboard printing machine has a sequentially connected paper feeding unit, a dust removal unit, multiple sets of printing machine units, a drying unit and a die-cutting unit. In the following, the paper feeding unit is arranged at the paper delivery unit of the corrugated cardboard printing machine. Counting sensor 1; a paper output counting sensor 5 is provided at the paper output of the drying unit as an example for illustration. However, according to the description of the following embodiments, those skilled in the art will know that the paper output counting sensor 5 can also be arranged in any working and post-processing unit in the dust removal unit, multi-color printing unit, dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com