Reaction device for preparing sodium silicate by utilizing high-efficiency and energy-saving liquid phase method

A high-efficiency, energy-saving, reaction device technology, applied in silicates, alkali metal silicates, sustainable manufacturing/processing, etc., can solve the problems of low production efficiency and high coal consumption, save energy, reduce heating time, and shorten heating effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

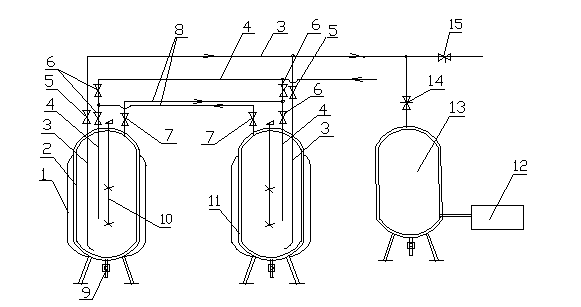

[0010] exist figure 1 Among them, the reaction device for preparing sodium silicate by the high-efficiency and energy-saving liquid phase method is carried out with a reaction device composed of parallel A reactor 2, B reactor 11 and air pressure bag 13 and a pipeline between the two reactors, Each reactor includes a water-cooled jacket 1 circulating on the outer wall of the reactor, a mixer 10 arranged in the reactor, and a cleaning valve 9 located at the bottom of the reactor. The two reactors are respectively connected with a discharge pipe 3 and a discharge pipe. After merging, it is connected to the storage tank (not shown in the figure), and each discharge pipe 3 connected to the reactor is provided with a discharge control valve 5, and the two reactors are respectively connected to a steam pipe 4. Connected to the boiler (not shown in the figure), two air intake control valves 6 are arranged on each steam pipe connected to the reactor, and the decompression and emptying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com