A compound mineral admixture for marine engineering reinforced concrete structure

A mineral admixture and reinforced concrete technology, applied in the field of compound mineral admixtures, can solve the problems of decreased stability of alkaline passivation film, corrosion of steel bars, reduction of concrete alkalinity, etc., to increase the migration performance of anti-rust molecules , reduce the use cost of enterprises, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

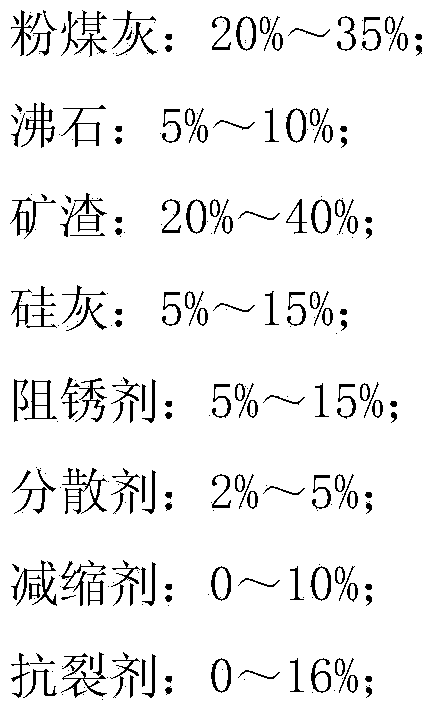

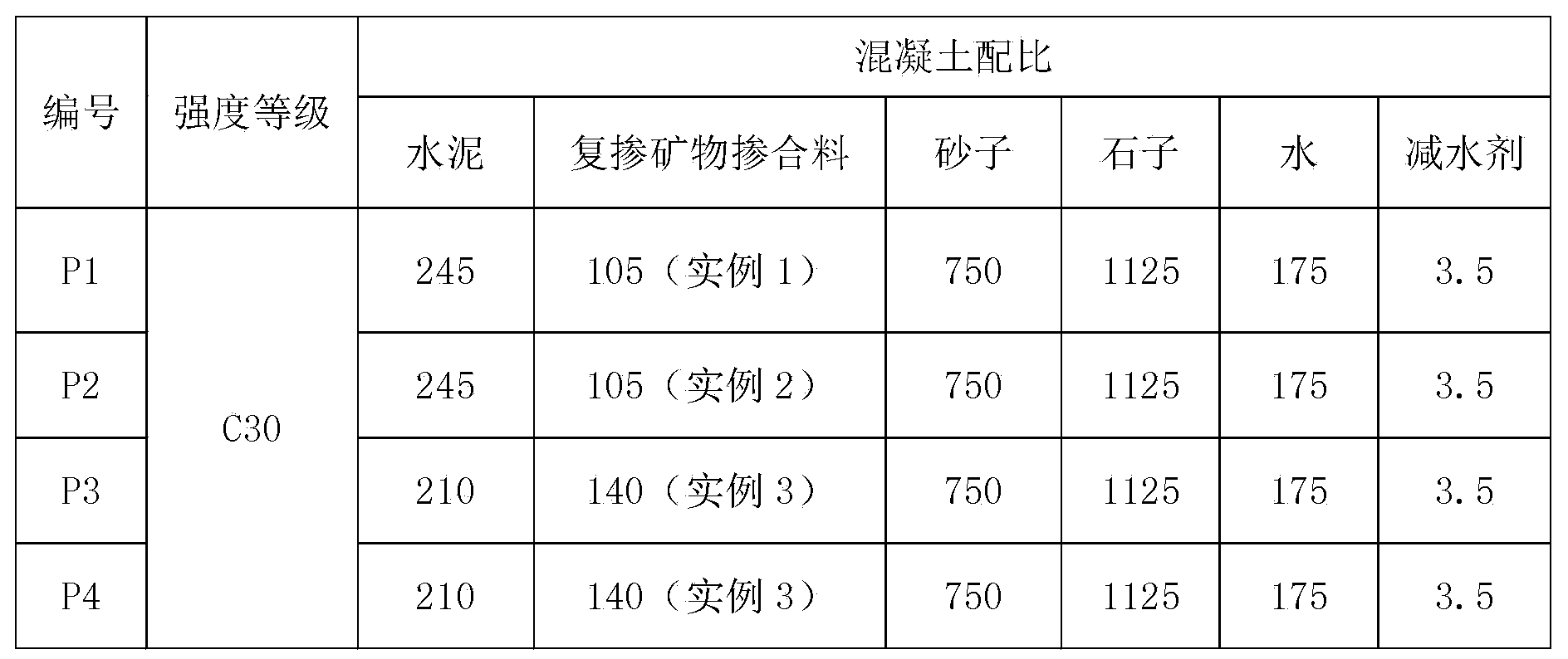

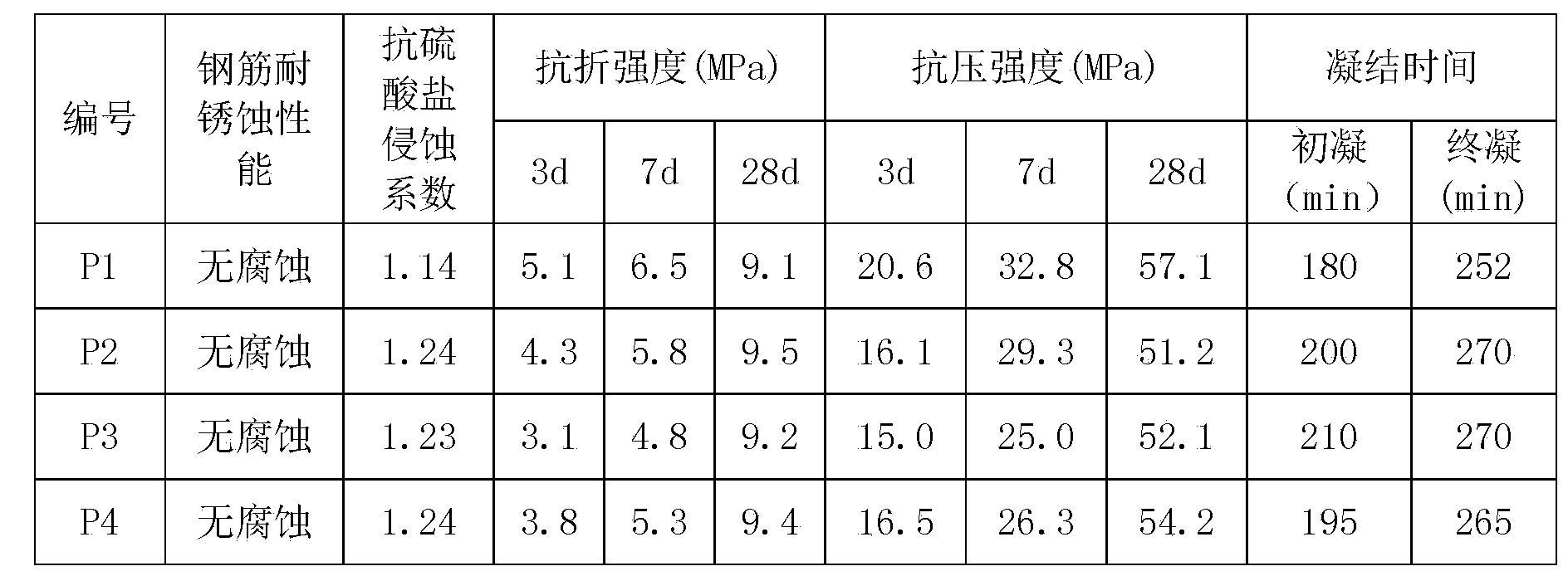

[0037] Embodiment 1: This kind of composite mineral admixture used for marine engineering reinforced concrete structure, according to the following component formula by mass percentage: fly ash: 35%; Zeolite: 5%; Slag: 40%; Silica fume: 10%; rust inhibitor: 5%; dispersant: 5%.

[0038] The formula is a new type of concrete admixture organically compounded by various ultrafine mineral components through a specific process. It is mainly based on slag powder and fly ash, and its mechanical properties such as early and late strength are further improved, so as to achieve reinforced concrete. Corrosion resistance, reducing the heat of hydration of concrete, improving the durability of concrete, and improving the early strength decline of concrete caused by the addition of a large number of mineral admixtures, and is suitable for marine reinforced concrete projects with severe chloride ion and sulfate erosion.

Embodiment 2

[0039] Embodiment 2: This kind of composite mineral admixture used for marine engineering reinforced concrete structure is formulated according to the following mass percentages: fly ash: 20%; zeolite: 10%; slag: 35%; silica fume: 5%; rust inhibitor: 15%; dispersant: 5%; shrinkage reducer: 10%.

[0040] The shrinkage-reducing component mixed in this formula can reduce the shrinkage of concrete, especially the early shrinkage, by adjusting the surface tension of the solution and other physical means. Improve the corrosion resistance of concrete. At the same time, the compound migratory rust inhibitor mixed in is beneficial to form a passivation film on the surface of the steel bar, and is suitable for reinforced concrete structures in severely corroded areas such as engineering and water level change areas.

Embodiment 3

[0041]Embodiment 3: This kind of composite mineral admixture used for marine engineering reinforced concrete structure is formulated according to the following mass percentages: fly ash: 20%; zeolite: 5.5%; slag: 30%; silica fume: 5%; rust inhibitor: 15%; dispersant: 3.5%; shrinkage reducer: 5%; anti-crack agent: 16%.

[0042] The formula is mixed with an appropriate amount of composite anti-crack components, so as to reasonably and effectively compensate the shrinkage of concrete, reduce cracks and micro-cracks caused by shrinkage of concrete, and improve the anti-crack and impermeability of concrete. The compound anti-cracking component added not only contains the common anti-cracking agent that works in the early stage, but more importantly, it is compounded with the long-term micro-cracking anti-cracking component that has a good anti-cracking effect in the later stage, so that it is easier to ensure a good performance in compensating the shrinkage of the concrete. Effect....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com