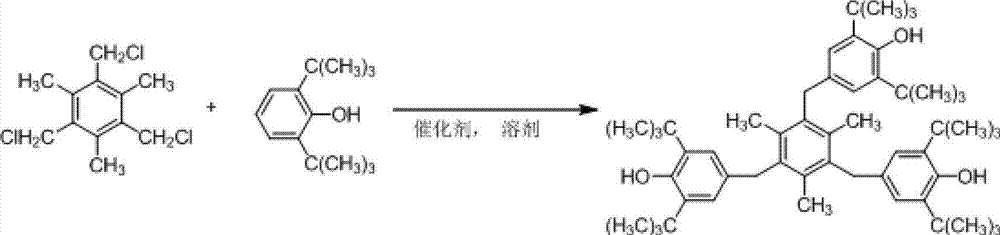

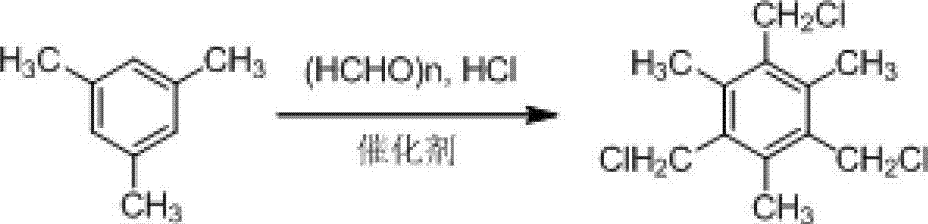

The preparation method of hindered phenolic antioxidant 330

A technology of hindered phenols and antioxidants, which is applied in the field of preparation of hindered phenols antioxidant 330, can solve the problems of preparation of antioxidant 330 that have not been reported, and achieve easy separation and purification, mild reaction conditions, and cheap and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation process of silica-supported phosphotungstic acid catalyst is as follows: add 60kg of superfine silica (2500 mesh) and 40kg of phosphotungstic acid (CAS No.: 12501-23-4) in 200L water, soak for 24 hours at room temperature, and then After filtering, the filter cake was dried at 100°C for 3 hours, and then activated at 200°C for 3 hours to obtain a silica-supported phosphotungstic acid catalyst.

Embodiment 2

[0021] The preparation process of silica-supported phosphotungstic acid catalyst is as follows: add 20kg of ultrafine silica (6000 mesh) and 40kg of phosphotungstic acid (CAS No.: 12501-23-4) to 200L water in sequence, soak for 12 hours at room temperature, and then Filter, dry the filter cake at 100°C for 2 hours, and then bake and activate at 200°C for 2 hours to obtain the silica-supported phosphotungstic acid catalyst.

Embodiment 3

[0023] The preparation process of silica-supported phosphotungstic acid catalyst is as follows: add 100kg of ultrafine silica (1200 mesh) and 20kg of phosphotungstic acid (CAS No.: 12501-23-4) in 200L water in sequence, soak for 36 hours at room temperature, and then Filter, dry the filter cake at 100°C for 4 hours, and then bake and activate at 200°C for 5 hours to obtain the silica-supported phosphotungstic acid catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com