Feather washing and dewatering machine

A technology of washing and washing machine and down, which is applied in the field of down washing and washing machine, which can solve the problems of waste of water, dirty cleaning of feathers, and inability to realize precise cleaning control of feathers, and achieve the effect of improving the yield and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

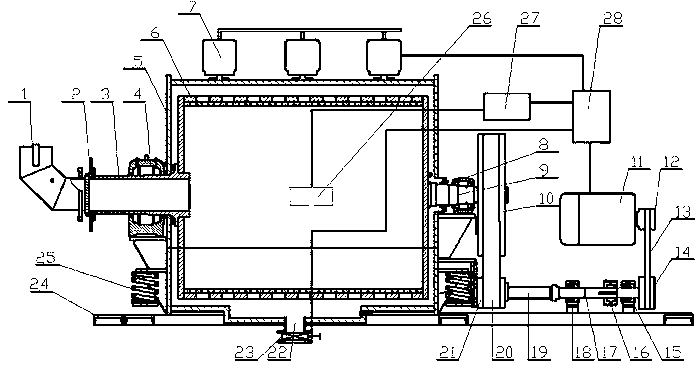

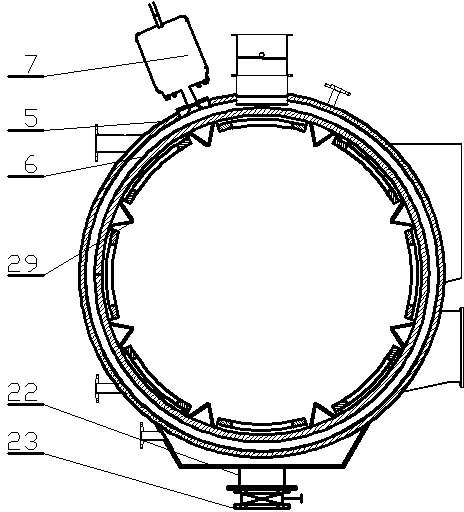

[0010] In the accompanying drawings, the eiderdown washing machine includes a chassis 24, a horizontal fixed cylinder 5 elastically mounted on the chassis 24, a plurality of pulse pluckers 7 installed on the top of the fixed cylinder 5, and a rotary connection to the fixed cylinder 5 inside. The drum 6 is a driving device for driving the drum 6 to rotate; it also includes a PLC electric control box 28 and a turbidity meter 27 connected to the PLC electric control box 28 , the sensor 26 of the turbidity meter 27 is installed in the fixed cylinder 5 .

[0011] The PLC electric control box 28 is connected with the water inlet system and the drainage system of the frequency conversion motor 11, the pulse depilator 7 and the washing machine respectively.

[0012] Described sensor 26 is installed on the inner wall of fixed cylinder 5, and it can be installed together with water level gauge.

[0013] The fixed cylinder 5 is a sealed cylinder, the two sides of the cylinder are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com