Neutron diffraction high-temperature goniometer and special mechanical loading device thereof

A technology of loading device and goniometer, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that restrict the development of high-end equipment manufacturing industry of new materials, lack of testing technology and instruments, etc., achieve light weight, realize precise control, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

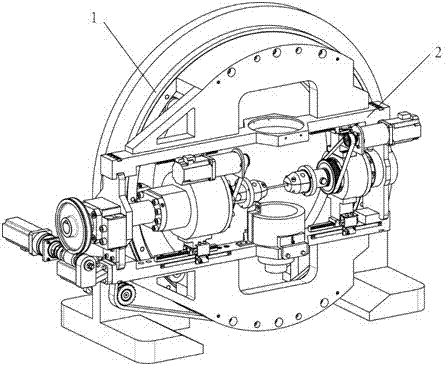

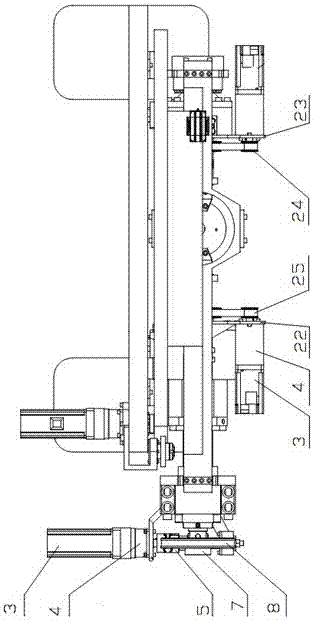

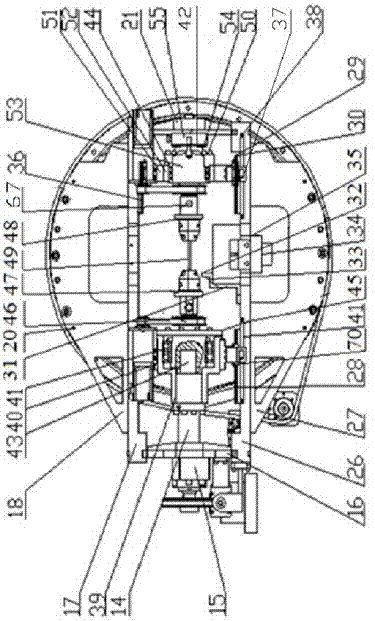

[0027] see figure 1As shown, the neutron diffraction high temperature goniometer and its special mechanical loading device of the present invention are mainly composed of two units: high temperature goniometer unit 1 and special mechanical loading unit 2 . The high temperature goniometer unit 1 can make the special mechanical loading unit 2 rotate within the range of 0°~90°, and record the angle value in real time. The special mechanical loading unit 2 provides load and thermal field loading for the tensile test piece 49, and has functions such as rotation of the tensile test piece 49, temperature detection, and load reading. The special mechanical loading unit 2 is connected with the high temperature goniometer unit 1 through bolts. The goniometer unit can rotate the mechanical loading system unit, and can real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com