Air bearing-air rib combined type film structure

A combination and membrane structure technology, applied in the direction of arch structure, special structure, dome structure, etc., to achieve the effect of increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

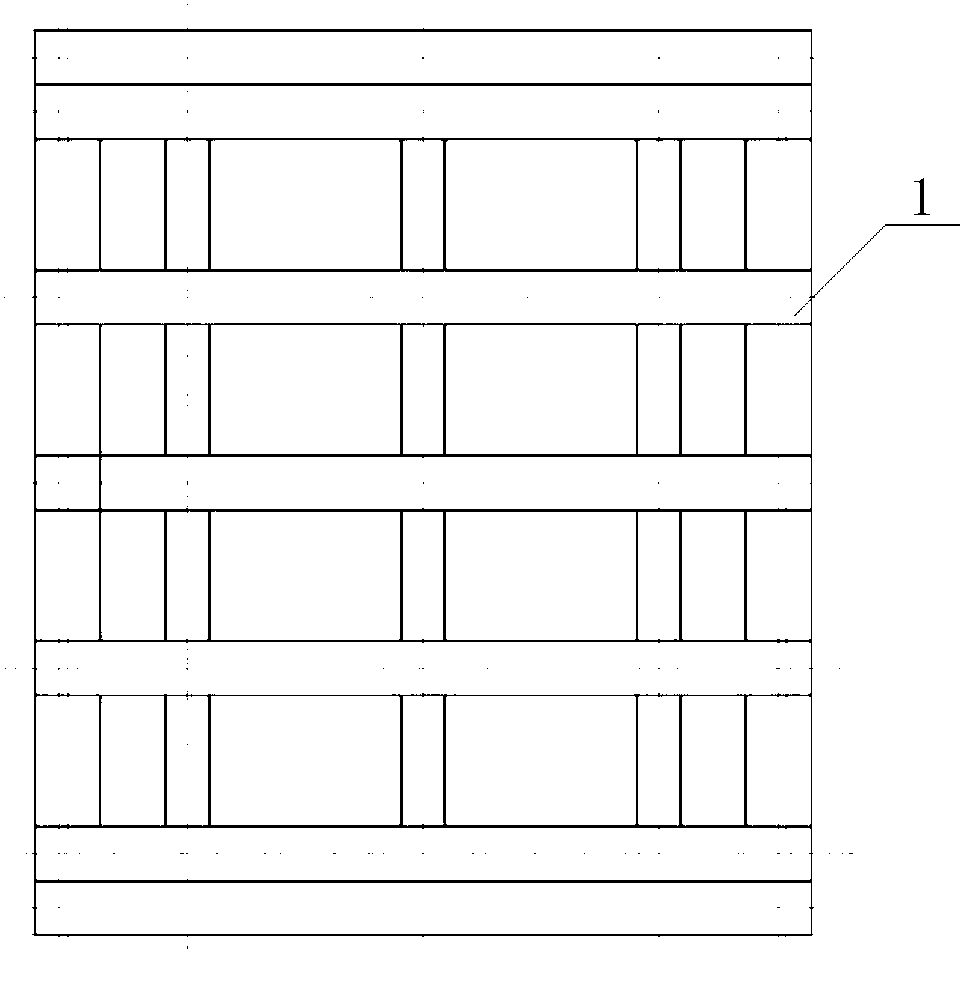

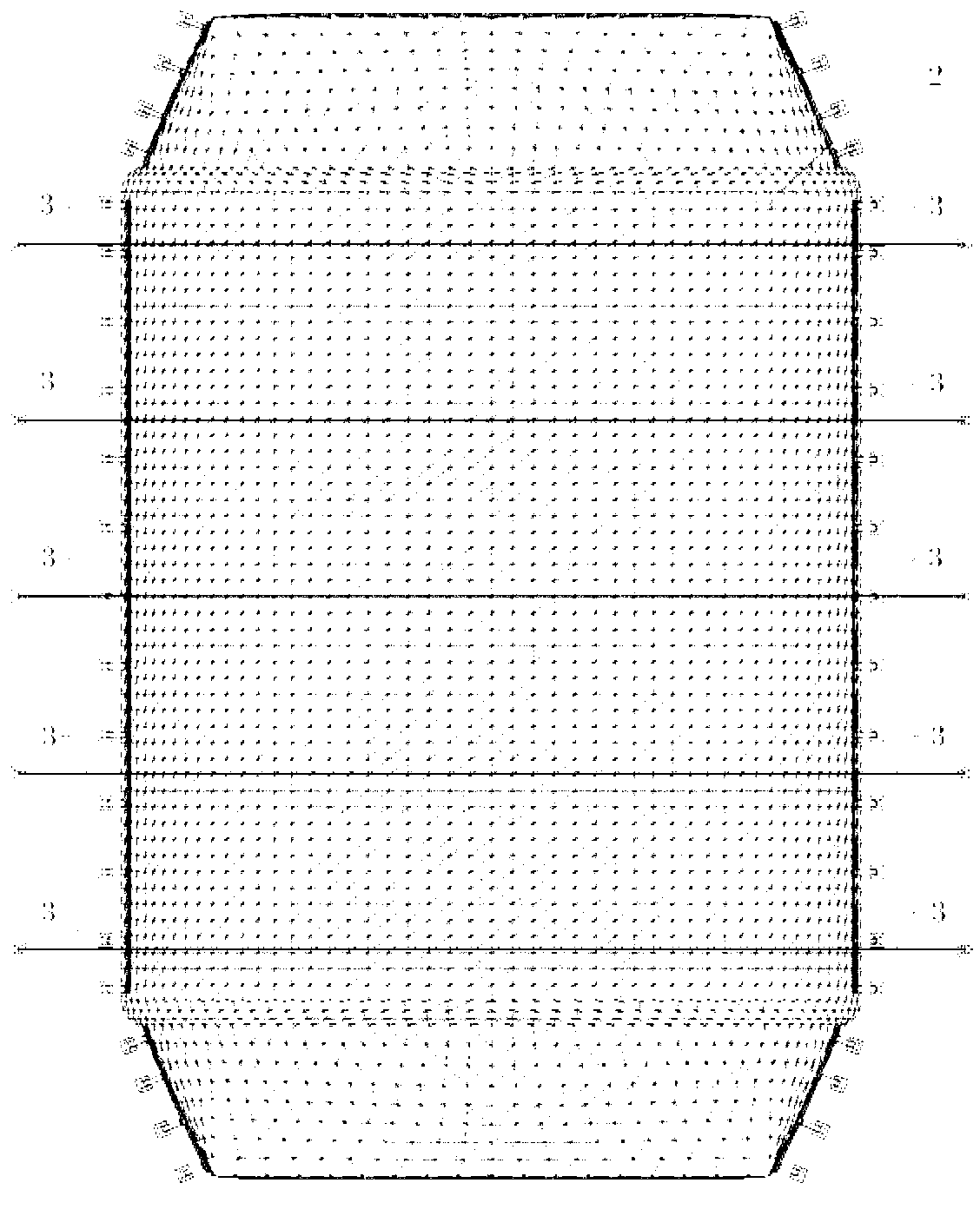

[0027] Air-bearing-air-rib combined membrane structure, including air-rib frame 1, air-bearing membrane 2 and cable 3, wherein the structure of air-rib frame 1 is as follows: figure 1 As shown, a plurality of inflatable rib members are combined into a skeleton structure, which is inflated by a blower to form and maintain the rigidity to form a supporting skeleton to bear the load. After the root inflatable rib members are fixed, the air-rib skeleton is obtained by increasing the air pressure. The structure of the air bearing membrane 2 is as follows figure 2 As shown, it is laid on the periphery of the air-rib frame 1, and the air pressure difference between the inside and the outside is maintained by inflation in the area enclosed by the air-bearing membrane 2. The cable 3 is fixedly connected to the outer side of the air-bearing membrane 2 through the diaphragm, and forms an integral structure with the air-bearing membrane 2. The cable 3 is connected to the ground by the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com