Heat radiating pipe with different wall thickness

A radiating pipe, unequal technology, applied in the field of intercooler, can solve the problems that cannot meet higher temperature, higher pressure strength, intercooler can not keep up with the speed of automobile development, cannot meet high temperature, high pressure, etc., to achieve The heat dissipation coefficient is improved, the heat dissipation performance is good, and the effect of improving production efficiency

Inactive Publication Date: 2013-03-27

TAIAN DINGXIN COOLER

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, intercoolers for trucks, buses, construction machinery, agricultural equipment, etc., mostly use harmonica tubes with 8 or less holes or wall-thick heat pipes with fins inside plugs, which have low heat dissipation efficiency and low structural strength. And other defects, can not meet the requirements of higher temperature, higher pressure strength

With the development of science and technology, especially the rapid development of the automobile industry, the cars produced are becoming more and more high-end, and the power is gradually increasing. The device has been far behind the speed of automobile development and cannot meet its high temperature and high pressure requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

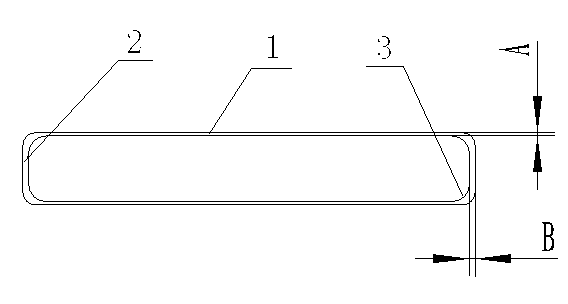

[0010] The thickness A of the long side of the rectangular section of the heat pipe is 0.35 mm, and the thickness B of the short side is 0.5 mm.

Embodiment 2

[0012] The thickness A of the long side of the rectangular section of the heat pipe is 0.5 mm, and the thickness B of the short side is 0.9 mm.

Embodiment 3

[0014] The thickness A of the long side of the rectangular section of the heat pipe is 0.35 mm, and the thickness B of the short side is 0.6 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a heat radiating pipe with different wall thicknesses. The cross section of the heat radiating pipe is rectangular; the thickness of the long edges of the rectangular cross section is not equal to that of the short edges of the rectangular cross section; the heat radiating pipe is formed by forming and high-frequency welding; and a welding seam is formed in the middle of the short edge at one end of the heat radiating pipe. The heat radiating pipe is good in heat radiating performance and high in bearing strength.

Description

technical field [0001] The invention relates to an intercooler, in particular to a radiating pipe with unequal wall thickness for the intercooler. Background technique [0002] At present, intercoolers for trucks, buses, construction machinery, agricultural equipment, etc., mostly use harmonica tubes with 8 or less holes or wall-thick heat pipes with fins inside plugs, which have low heat dissipation efficiency and low structural strength. And other defects, can not meet the requirements of higher temperature, higher pressure strength. With the development of science and technology, especially the rapid development of the automobile industry, the cars produced are becoming more and more high-end, and the power is gradually increasing. Devices have been far behind the speed of automobile development and cannot meet their high temperature and high pressure requirements. Contents of the invention [0003] The object of the present invention is to provide a heat dissipation ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02B29/04F28F1/04

CPCY02T10/146Y02T10/12

Inventor 周卫平

Owner TAIAN DINGXIN COOLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com