Labor-saving machine

A force machine and lever technology, applied in the field of labor-saving machinery, can solve the problems of unfavorable medium-high speed rotation, large resistance, no power balance device, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

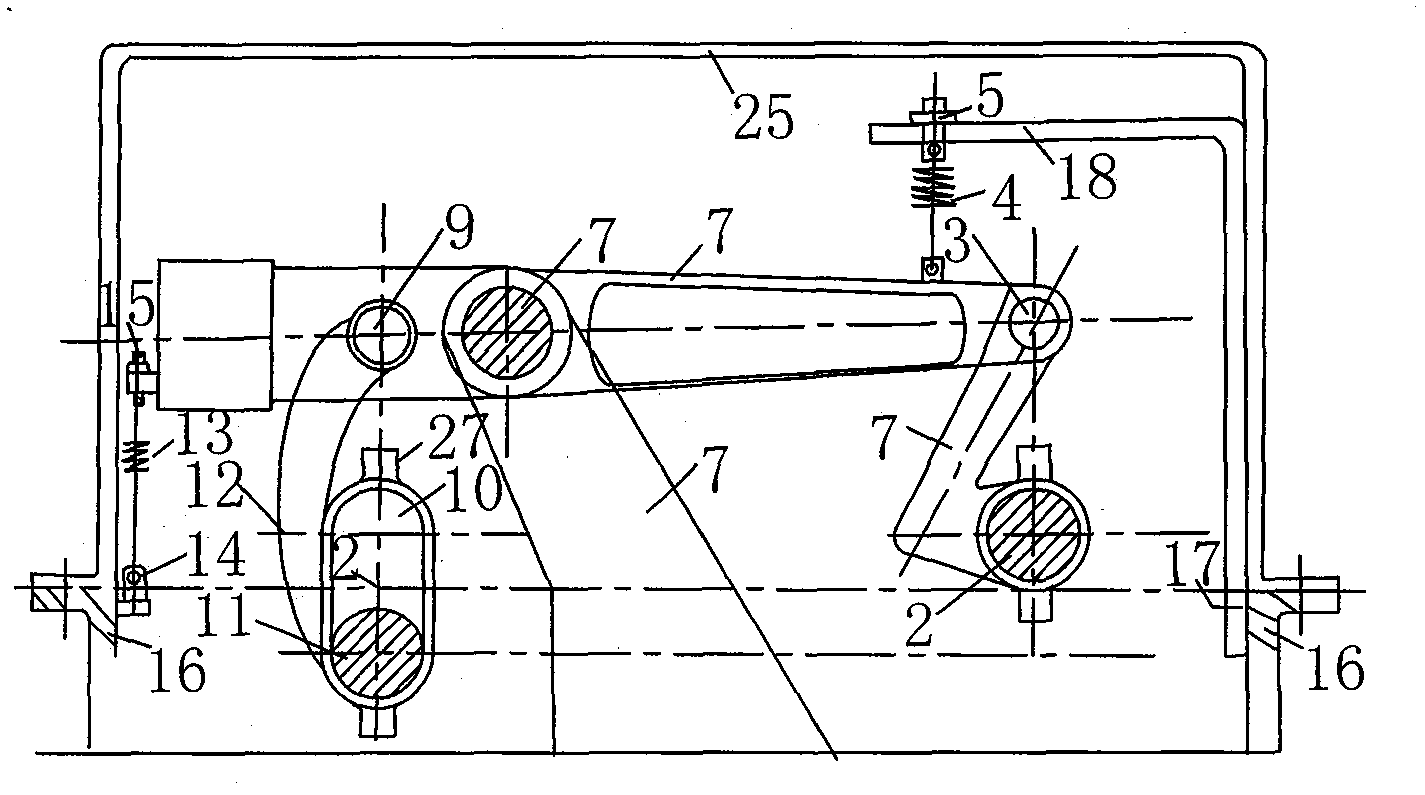

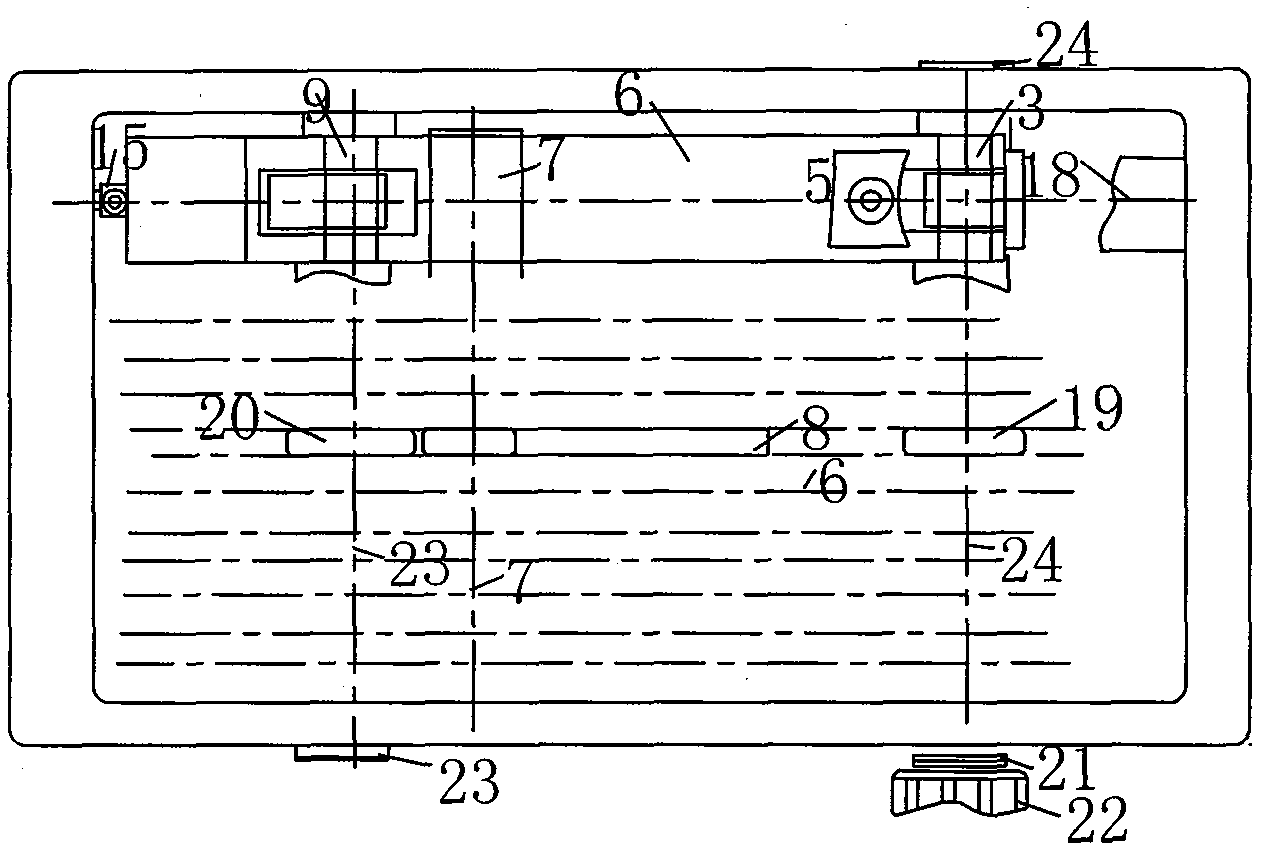

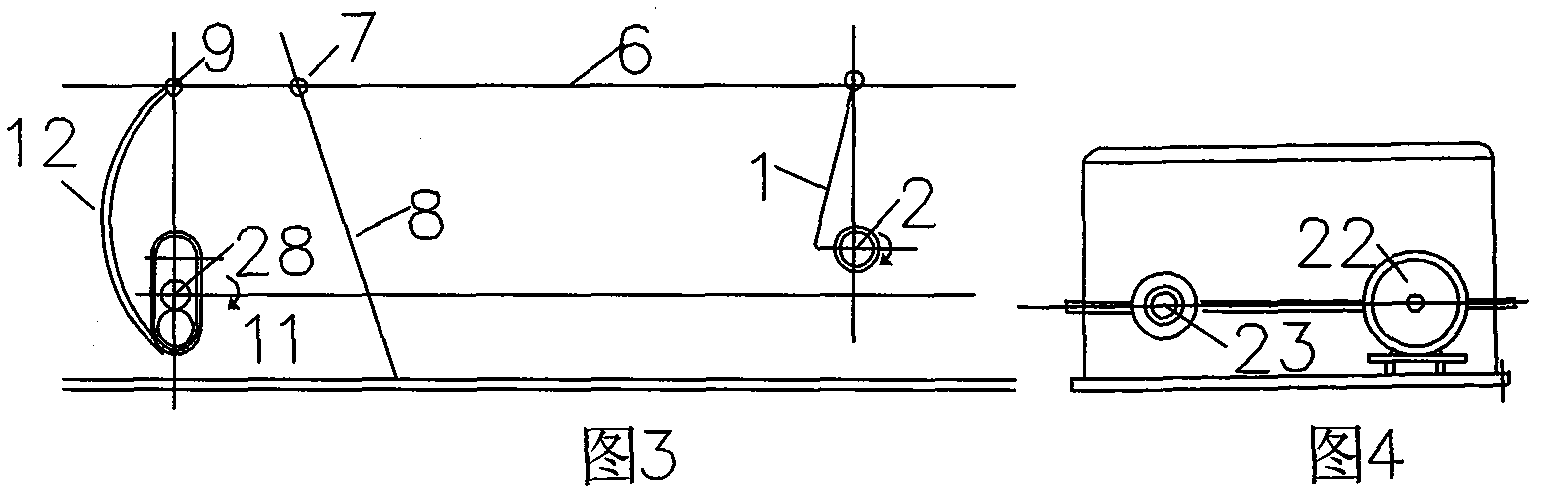

[0012] exist figure 1 Among them, the shaft of the front connecting rod 1 is set at an angle with the rod hole, and the movable pin shaft 3 of the front crank shaft 2 must be continuously connected with one end of the long arm of the lever 6, and the spring 4 is fastened with the adjustment bolt 5 of the lever 6 and the spring bracket 18 respectively. Part 17 is connected on the box body 16, and support shaft 7 is a through shaft that passes in the hole of support frame 8, and the bottom plate of support frame 8 is connected with the bottom plate of box body 16, and rear connecting rod 12 shafts are curved upper ends with dynamic The pin shaft 9 is movably connected in the hole at the short arm end of the lever, and the lower end is connected with the bottom of the long hole 10 of the rear connecting rod. It is connected with the adjustment bolt 15 and the spring seat 14 on the side of the box body 16. The front crankshaft 24 and the rear crankshaft 23 are installed on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com