Wire wound hose

A technology of wire winding and hose, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problem of unsuitable fiber hose, and achieve good rigidity and toughness, good flame retardancy and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

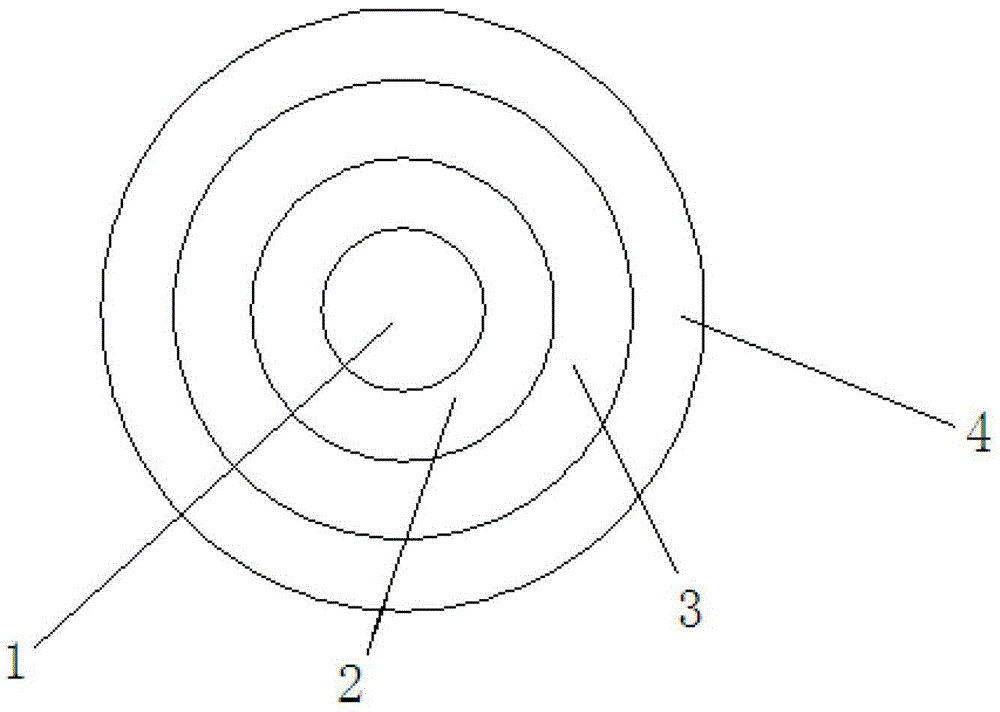

[0024] see figure 1 , a steel wire wound hose, including a pipe body, the pipe body is composed of a multi-layer structure, and the multi-layer structure is sequentially from the inside to the outside of the inner layer of modified nylon 6-layer 1, The polyurethane layer 2 of the second layer, the steel wire braided layer 3 of the third layer and the polyurethane layer 4 of the outermost layer.

[0025] The steel wire braided layer 3 of the third layer is a single-layer steel wire braided layer or a double-layer steel wire braided layer or a three-layer steel wire braided layer.

[0026] Modified nylon 6 material is made of the following raw materials in parts by weight:

[0027] Polyvinyl chloride 10, nylon 6100, ABS high rubber powder 5, poly-4-methyl-1-pentene 5, acrylate impact modifier ACR2, bisphenol A polycarbonate 8, crosslinking agent TAC2 , wollastonite powder 10, nano clay 5, 2-mercaptobenzimidazole 2, antioxidant OD2, antioxidant NBC2, methyltriethoxysilane 2, bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com