Convective microwave oven

A microwave oven and convection chamber technology, which is used in household stoves/stoves, household heating, lighting and heating equipment, etc., can solve the problems of low wind speed of centrifugal fans, slow cooking speed, and high temperature at the rotating shaft, so as to improve the heat dissipation effect, The effect of preventing excessive accumulation and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] The convection microwave oven of the present invention comprises a microwave oven body; a cooking cavity formed inside the microwave oven body; and an electronic accessory room provided with various electronic components. A cavity door constituting the front side of the microwave oven body and used for opening and closing the cooking cavity is installed on the front panel.

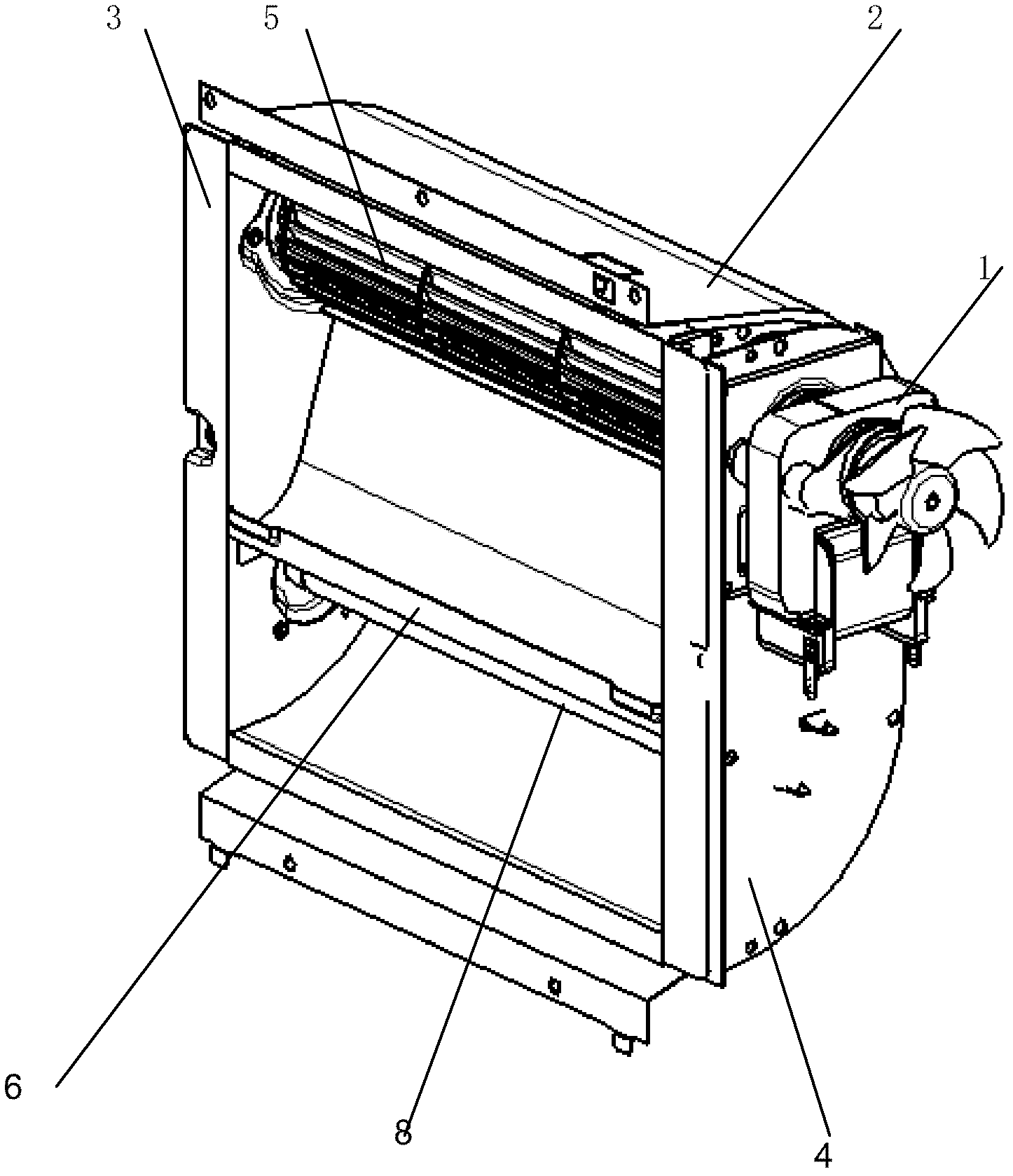

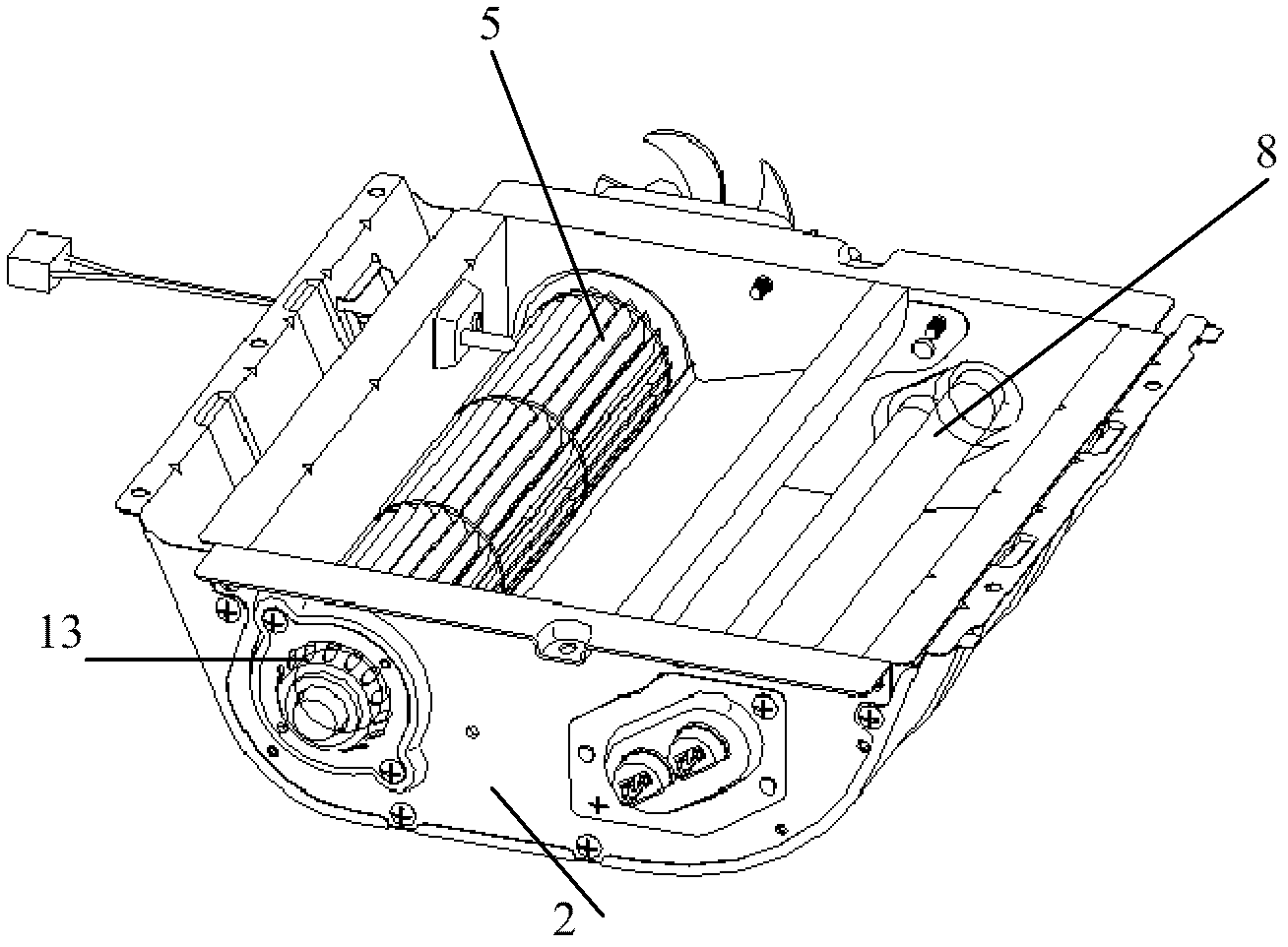

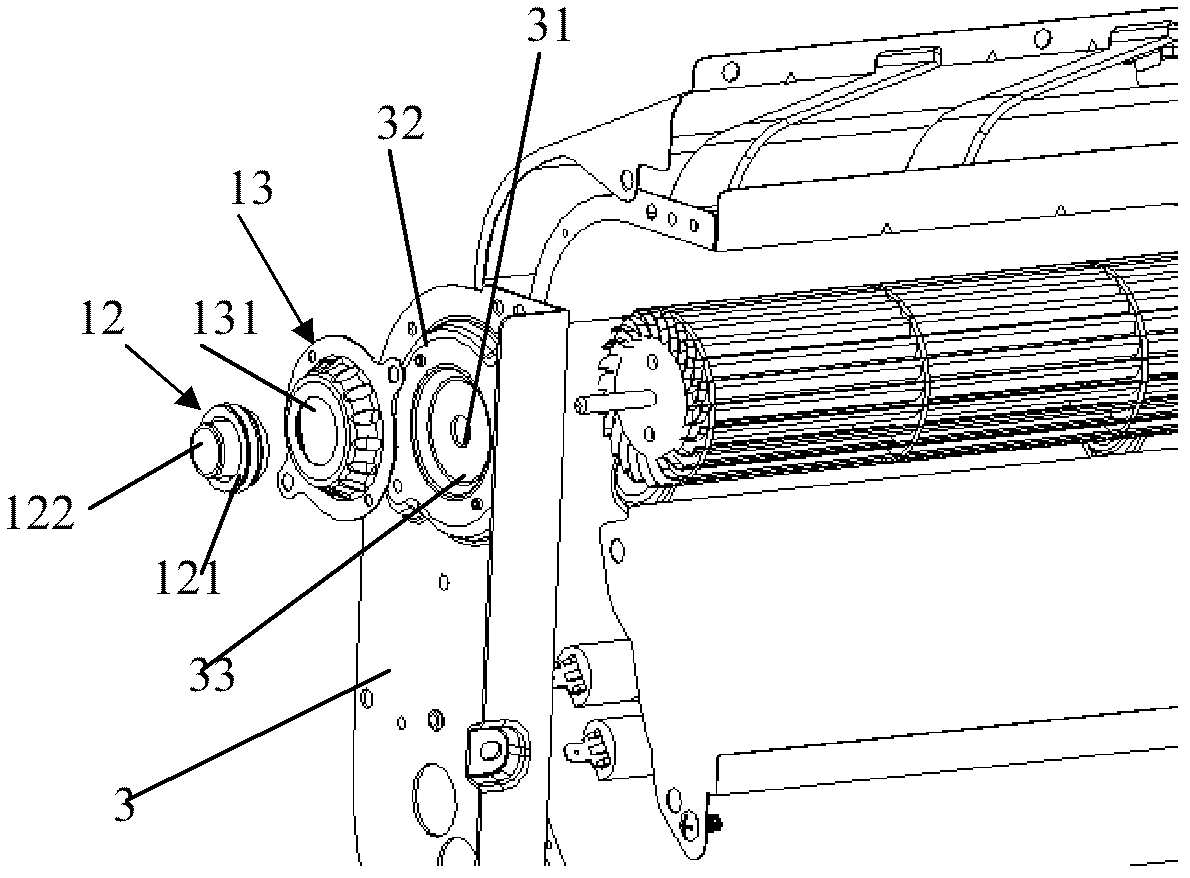

[0021] A plurality of communication holes communicating with the cooking cavity are formed on the rear panel of the microwave oven cooking cavity, and a convection chamber is arranged behind the rear panel. Such as figure 1 As shown, the convection chamber of the present invention is formed by a rear panel (not shown in the figure), a volute 2 that is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com