Drying process for preventing dried iron core from rusting

A drying process and iron core technology, applied in the field of transformers, can solve the problems of water vapor saturation and more oxygen, and achieve the effect of reducing oxygen content and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in detail.

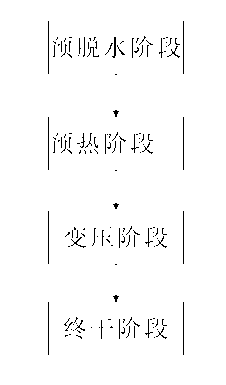

[0024] A drying process to prevent the iron core from rusting after drying, including four main stages: pre-dehydration stage, preheating stage, pressure transformation stage and final drying stage, such as figure 1 shown. Each stage is as follows:

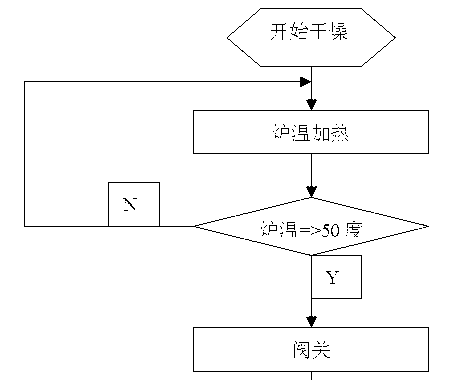

[0025] Pre-dehydration stage: only heat the air in the drying furnace, the hot air quickly changes the original temperature field, the temperature of the entire iron core begins to rise, but the moisture in the iron core coil has not yet evaporated, until the temperature in the drying furnace reaches 50°C; Such as figure 2 shown.

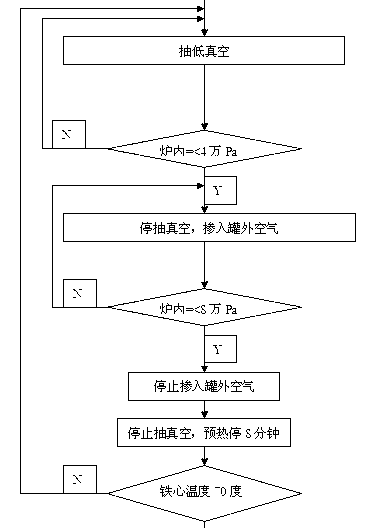

[0026] Preheating stage: continue to heat the air in the drying furnace, and the moisture in the iron core coil begins to evaporate. When the water vapor in the tank reaches saturation, start vacuuming to remove part of the evaporated water vapor until the air pressure in the drying furnace As low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com