Automatic testing device and method of power module

A technology for automated testing and power supply modules, applied in the direction of power supply testing, etc., can solve the problems of increasing the workload of test workers, increasing the total test time, reducing production efficiency, etc., to achieve a simple and reliable test method, improve test efficiency, and reduce input costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

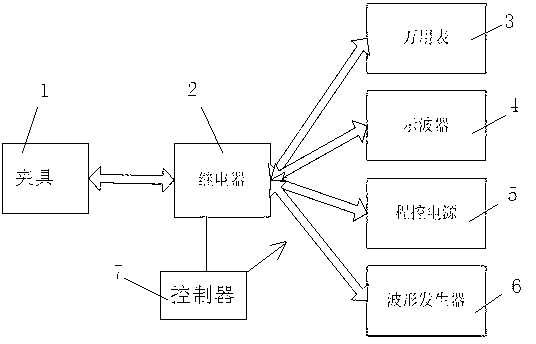

[0009] see figure 1 , the present invention has a fixture 1 for fixing the power module under test, and there is a power supply for the power module under test to work in the fixture 1 . The fixture 1 is connected to the relay 2, and the relay 2 is respectively connected to different test equipment such as a multimeter 3, an oscilloscope 4, a programmable power supply 5, and a waveform generator 6. The relay 2 is connected to the controller 7 through a serial port or other methods, and the controller 7 is also connected to various test equipment. For an ordinary power module, the test points generally involve parameters such as voltage value, current value, waveform frequency, peak-to-peak value, etc., and these parameters can be obtained by reading the test equipment through the controller 7 .

[0010] The necessary operating voltage is output by the test equipment, and the test of the first test point in the power module is started. For example, using the multimeter 3 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com