Aluminum-gate semiconductor device and manufacturing method thereof

A technology of a semiconductor and a manufacturing method, applied in the field of aluminum gate semiconductor devices and their manufacturing, can solve the problems of increasing turn-on voltage, affecting circuit turn-on, and difficulty in meeting the requirements of resistance value and semiconductor device parameters at the same time as the impurity concentration of P-type well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

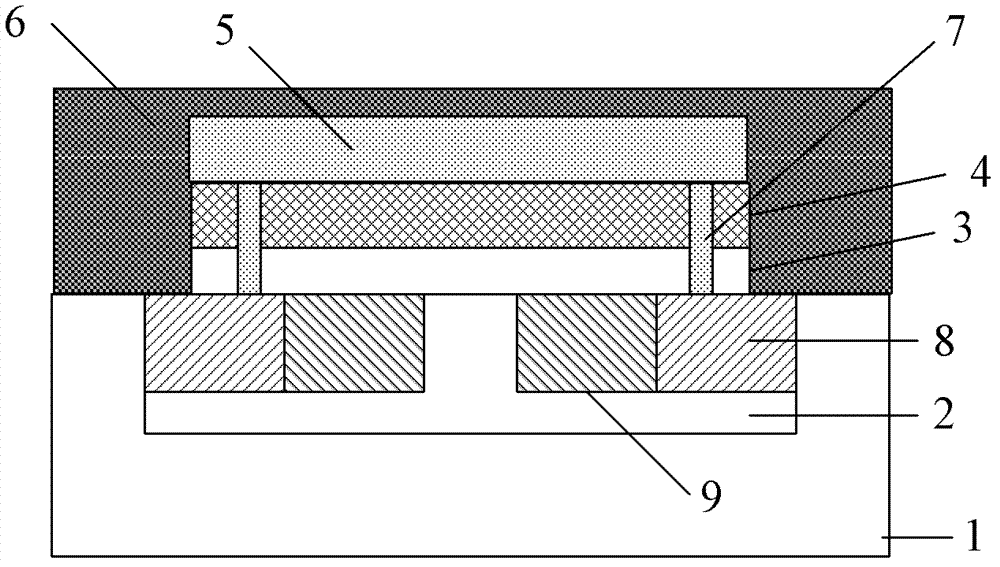

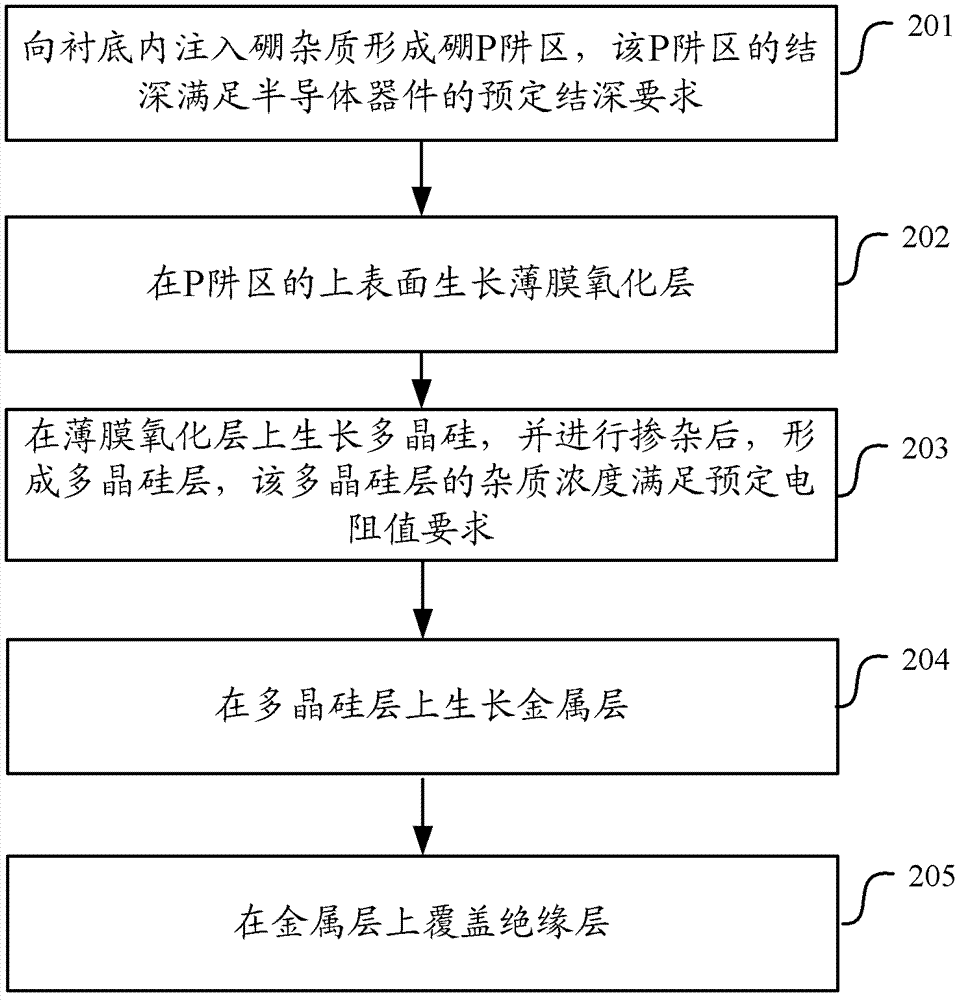

[0046] An embodiment of the present invention provides an aluminum gate semiconductor device, such as figure 1 As shown, the aluminum gate semiconductor device includes:

[0047] A boron P well region 2 located in the substrate 1, the junction depth of the boron P well region 2 meets the predetermined junction depth requirements of aluminum gate semiconductor devices;

[0048] A thin film oxide layer 3 located on the upper surface of the boron P well region 2;

[0049] The polysilicon layer 4 located on the upper surface of the thin film oxide layer 3, the impurity concentration of the polysilicon layer 4 meets the predetermined resistance value requirement;

[0050] a metal layer 5 located on the surface of the polysilicon layer 4;

[0051] The insulating layer 6 located on the surface of the metal layer 5 .

[0052] Preferably, the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com