Anti-corrosion resistance-reducing lightning protection grounding device adopting multi-component alloy grounding body

A multi-alloy, lightning protection and grounding technology, applied in the direction of connecting contact materials, etc., to achieve the effect of good anti-corrosion and resistance reduction, lightning protection and grounding effect, good leakage effect, and complete protection function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

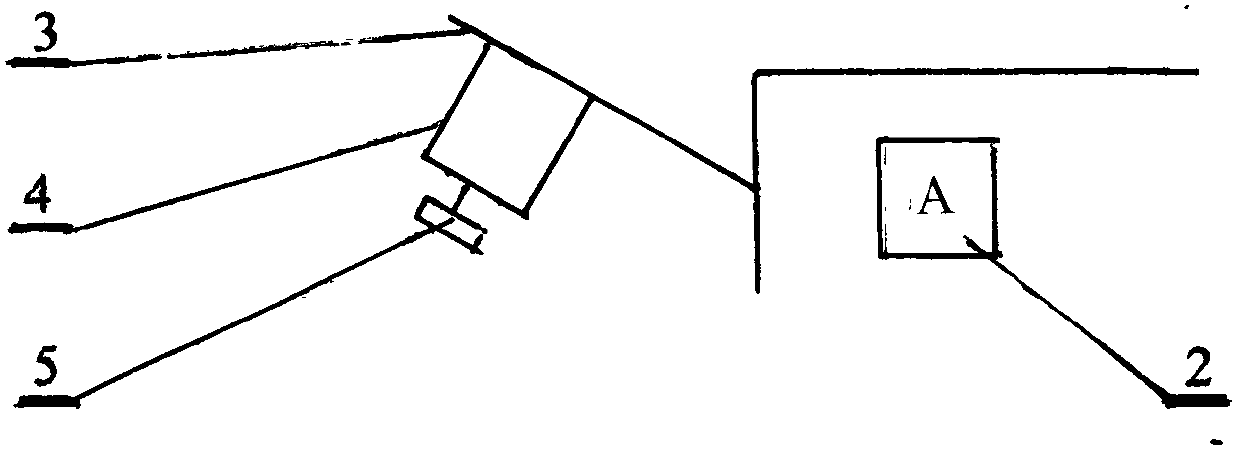

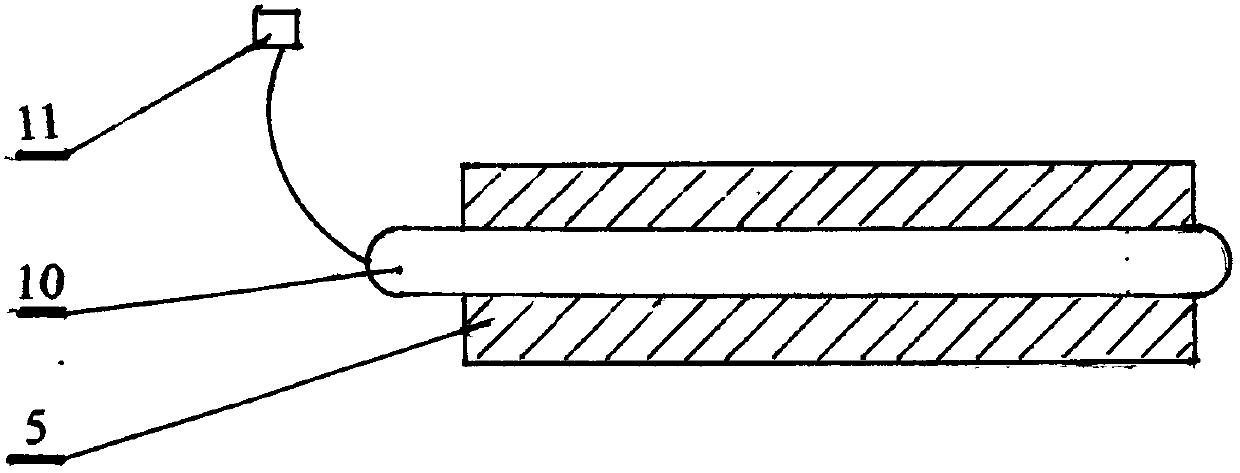

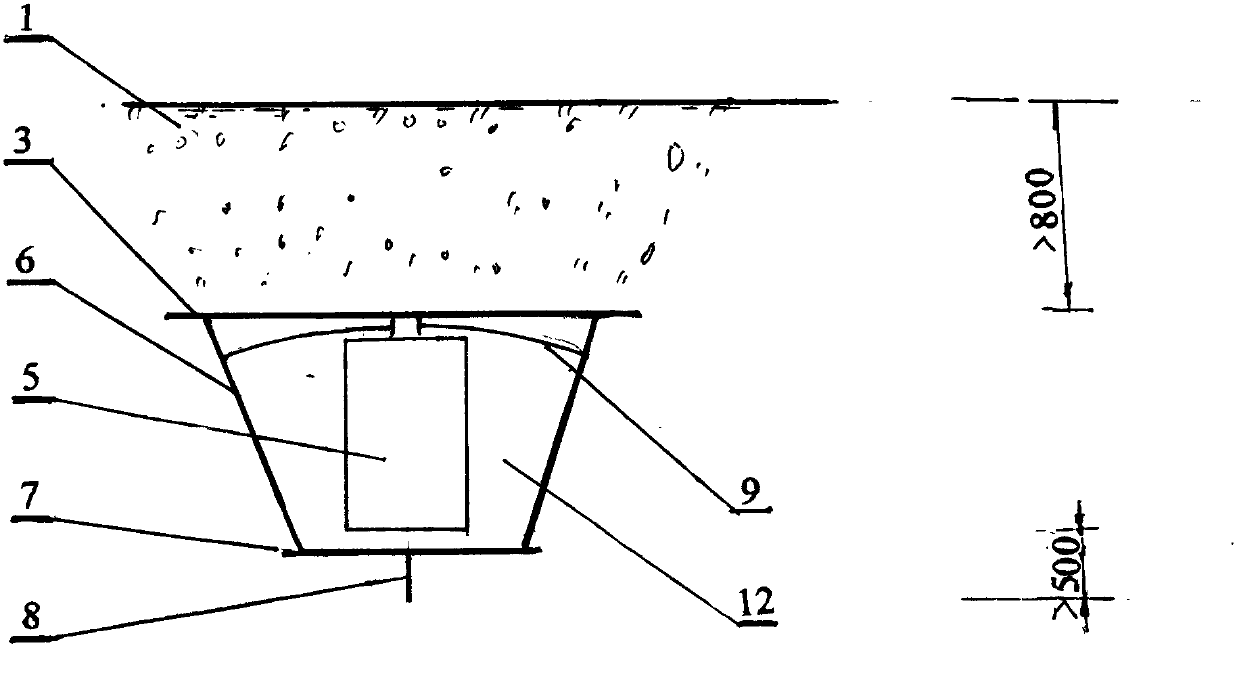

[0013] As shown in the figure, there are grounding steel belt 3, grounding bus bar 4, and alloy grounding body 5 under the tower foundation 2; In one body, the electrolyte material 12 is located in the middle, and the alloy grounding body 5 of the present invention is provided with a red copper rod 10 processed by silver technology, and the red copper rod 10 is cast in the alloy grounding body 5, and the red copper rod 10 processed by silver technology has a For the cable, the copper rod 10 is brazed and connected with the cable, and the other end of the cable is connected with a steel plate and the grounding steel belt 3; the alloy grounding body 5 is cast from magnesium, manganese, zinc, and aluminum multi-element metals, and the multi-element alloy grounding body 5 is 750mm ×300mm×300mm cuboid shape. The multi-element alloy ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com