Carbon fiber composite alloy grounding body

A composite alloy, grounding body technology, applied in the direction of connection, coupling device, connection contact material, etc., can solve the problems of less use, high price, corrosion of iron materials, etc., to achieve good leakage, complete protection function, high mechanical the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

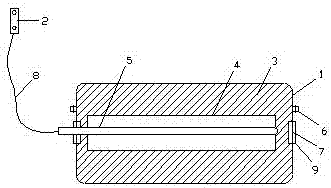

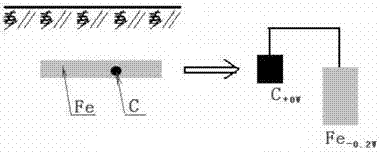

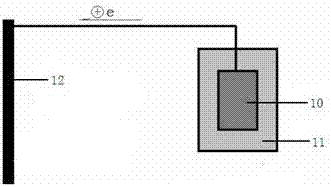

[0017] like figure 1 As shown, a carbon fiber composite alloy grounding body includes a casing 1 and a grounding steel strip 2, the casing 1 is a carbon fiber composite casing, the detection potential of the carbon fiber composite casing is 0V, and the casing 1 is filled with Electrolyte packing material 3, the electrolyte uses bentonite as the matrix material, and does not pollute the environment. The alloy body 4 is inserted into the electrolyte packing material 3, and the potential of the alloy body 4 is about -1.17V. The alloy body 4 and the shell The body 1 constitutes the positive and negative poles of the battery, which increases the number of free electrons in the soil, resulting in a decrease in grounding resistance. A copper rod core 5 runs through the alloy body 4, and the alloy body 4 is located in the middle of the casing 1. The copper rod core 5 is located in the middle of the alloy body 4, a pair of sealing ports 6 and filling ports 7 are respectively provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com