Bearing affixation structure and steering gear unit using bearing affixation structure

A technology for fixing structures and bearings, applied in the directions of bearing elements, rigid brackets of bearing components, bearings, etc., can solve the problems of rising manufacturing costs, difficult machining, and complex shape of the locking groove 27, and achieve the effect of preventing the locking and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

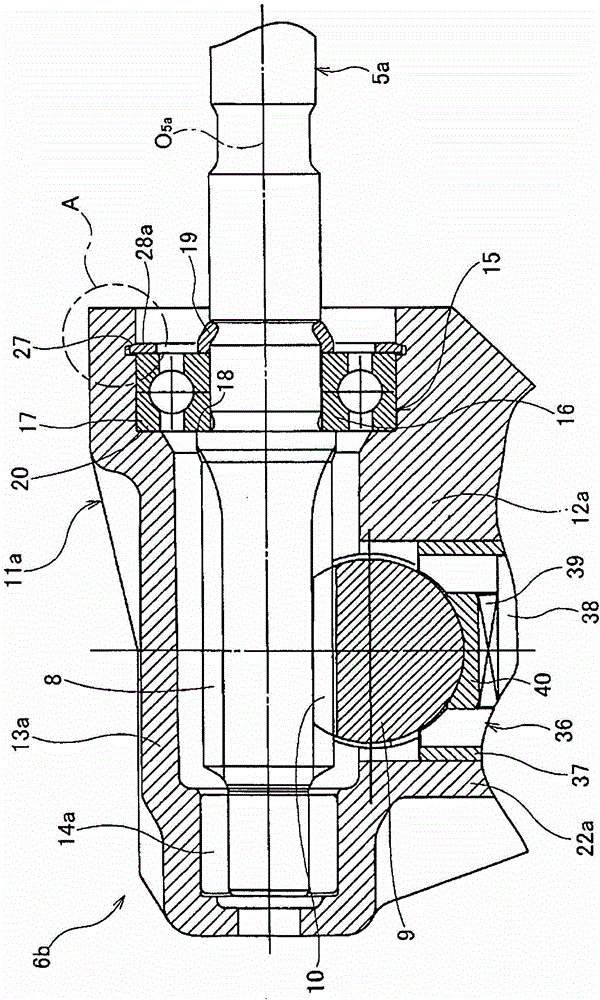

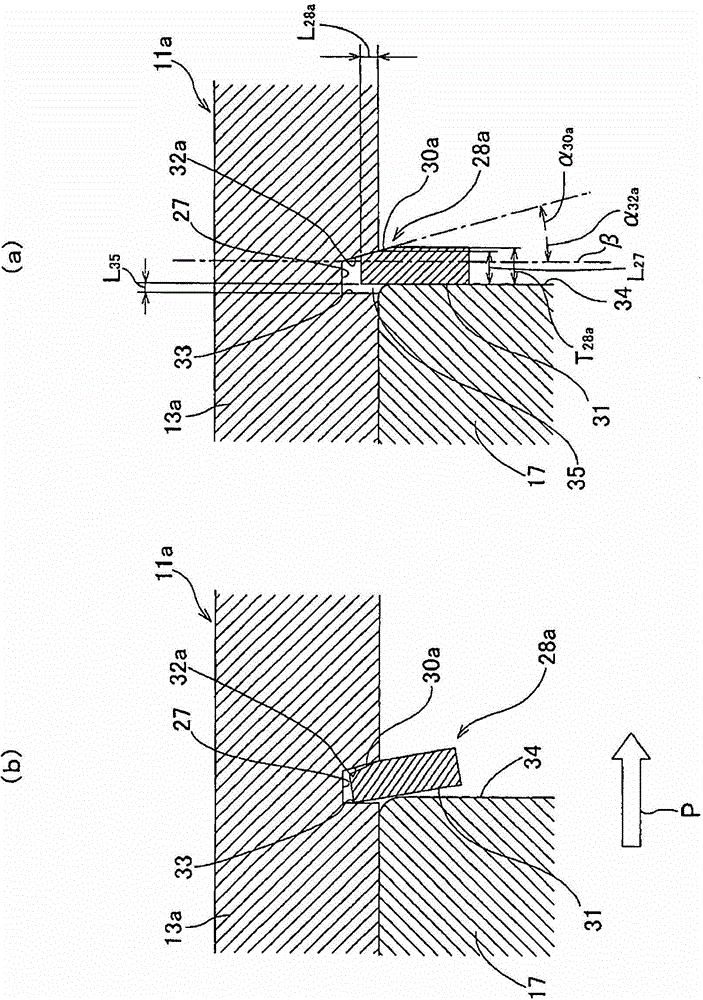

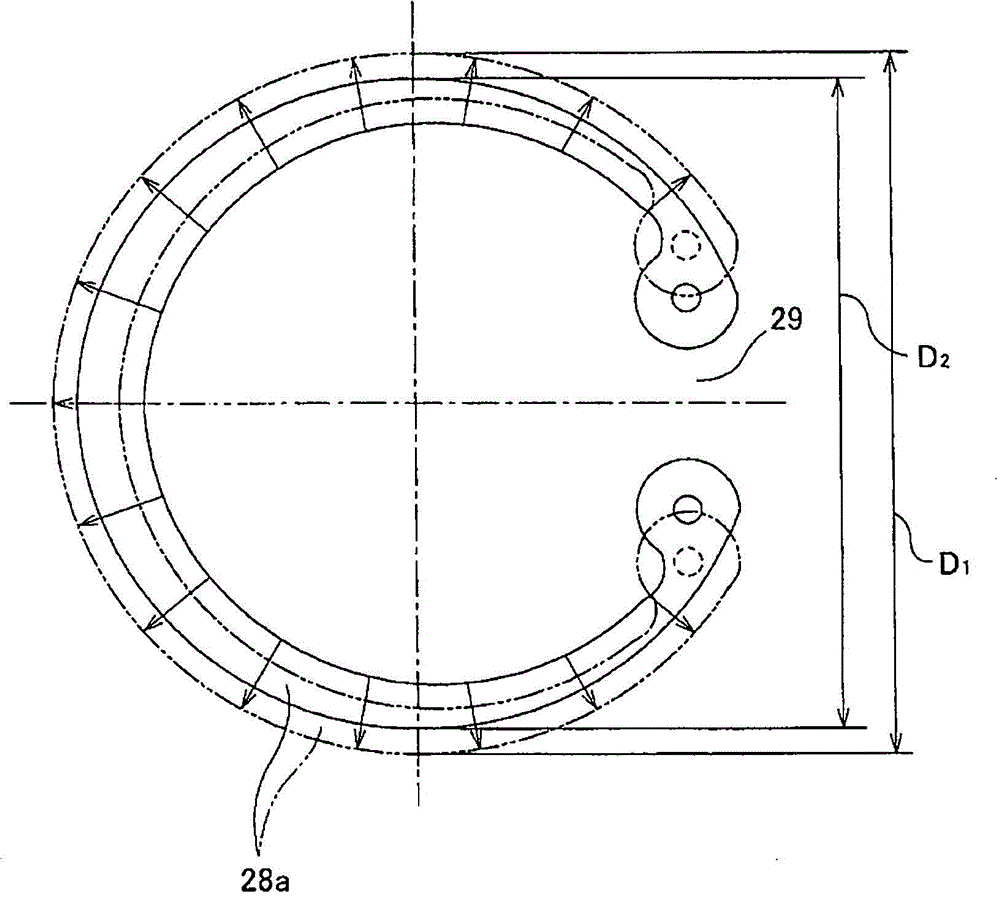

[0043] In the following, several embodiments of the bearing fixing structure of the present invention will be applied to a rack-and-pinion steering gear unit for fixing the outer ring of the first bearing fitted in the middle part of the pinion shaft to the inner peripheral surface of the housing. The situation is taken as an example and will be described in detail with reference to the accompanying drawings.

[0044] [First example of embodiment]

[0045] Figure 1 ~ Figure 3 The first example of the embodiment of the present invention is shown. The present invention is characterized in that it designs a structure for fixing a bearing to a structural member such as a casing using a tapered split ring in a mechanical device such as a rack-and-pinion steering gear unit. As for the structure of other parts constituting the mechanical device including the steering gear unit, various conventionally known structures can be adopted as long as the present invention is applicable. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com