Targeted spray machine with automatically adjusted and controlled air inlet

An air inlet and sprayer technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of low degree of automation and inability to change the size of the air inlet, and achieve precise application and improved application. The effect of technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

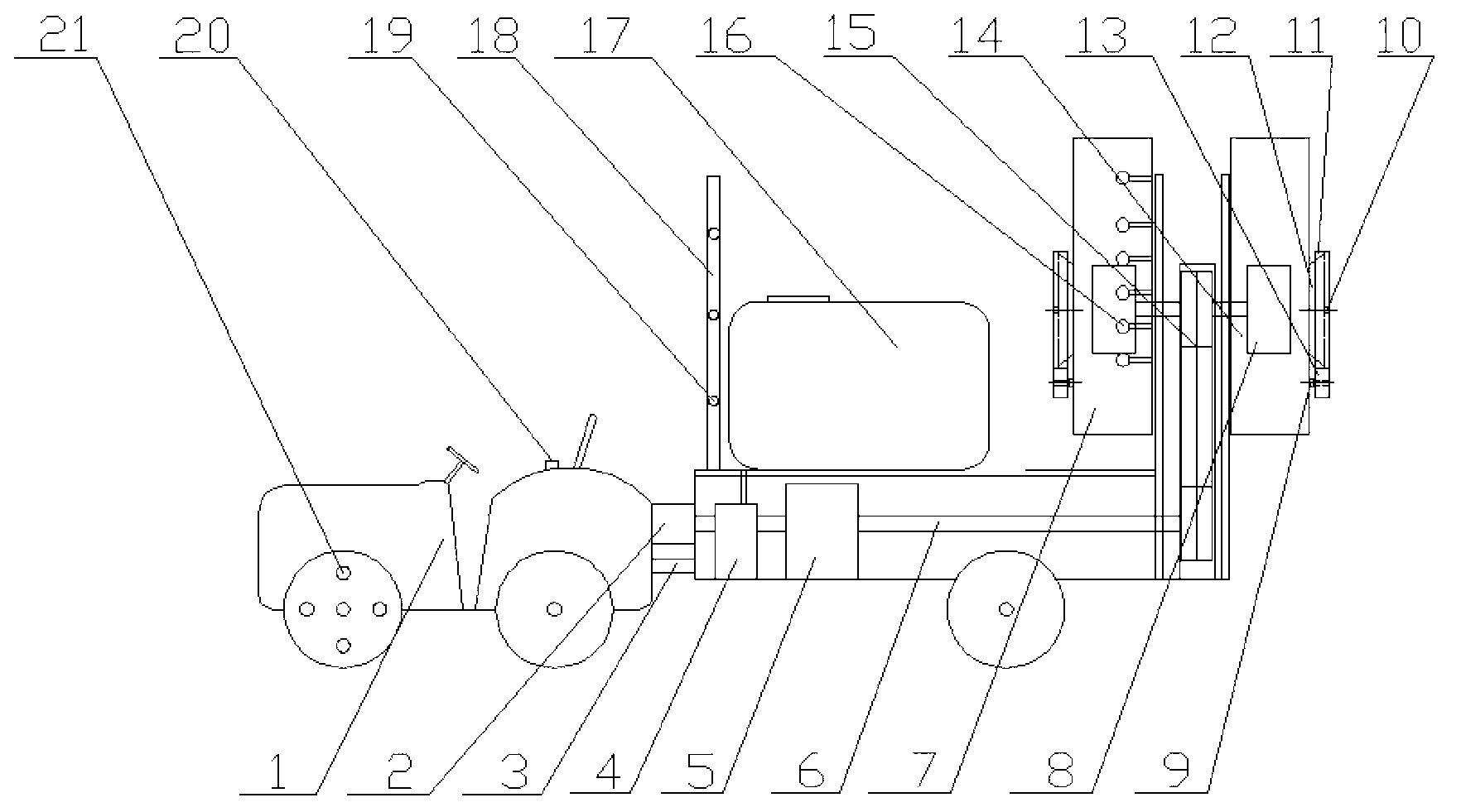

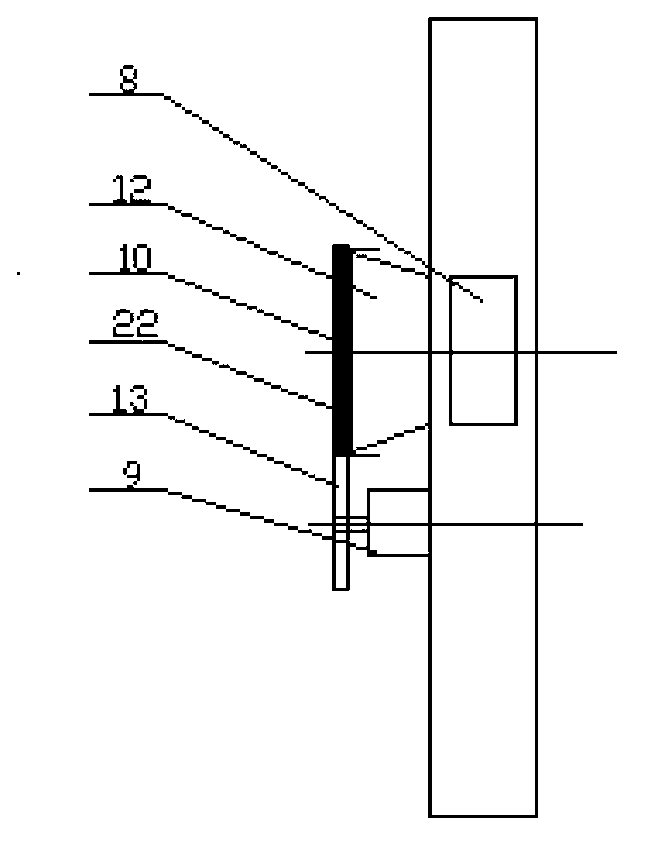

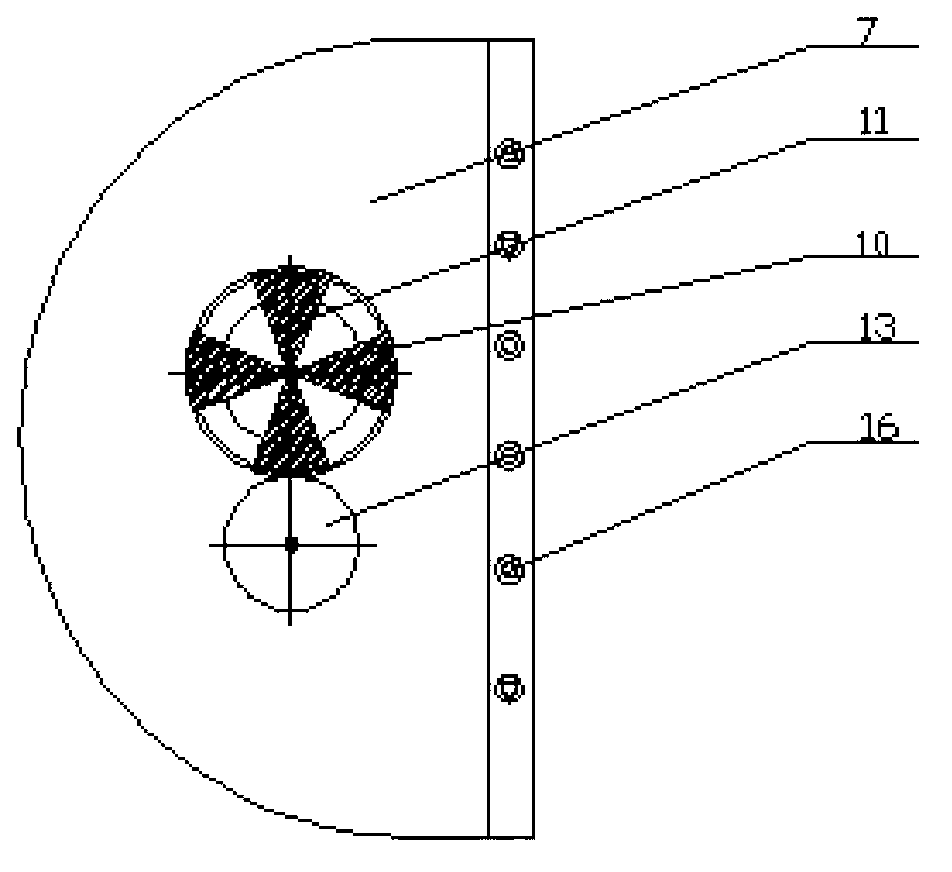

[0020] Such as figure 1 As shown, the present invention is a kind of air inlet automatic control type target sprayer, and the whole device is installed on the sprayer chassis 3 loaded on the tractor 1, including the left diversion bellows 7 and the right diversion bellows 14, all connected in the bellows To the nozzle 16 of the medicine box 17 and the centrifugal fan 8 whose wind direction is towards the nozzle 16, a hydraulic pump 4 is arranged on the pipeline between the medicine box 17 and the nozzle 16 to realize the pumping of the medicinal liquid. The spraying system adopts a traction structure, and is connected to the gearbox 5 through the transmission shaft 6, and the gearbox 5 is connected to the power output part of the tractor 1 through the universal coupling 2. The air inlets of the two bellows are all provided with a tapered air inlet device 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com