Vacuum concentrator

A vacuum concentrator, heater technology, applied in evaporator accessories, chemical instruments and methods, evaporation, etc., can solve problems such as solvent loss and vacuum equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

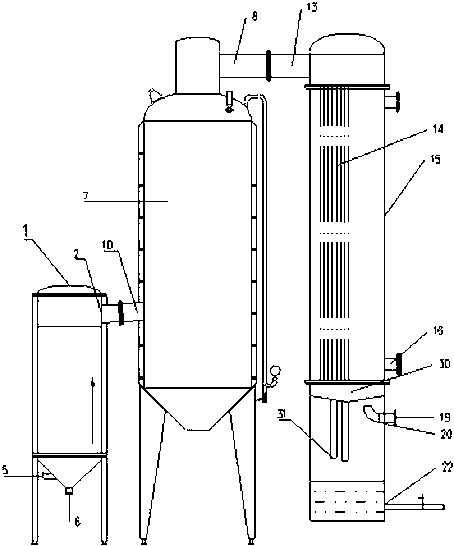

[0051] Vacuum concentrator of the present invention such as figure 1 As shown, a heater 1 is included, and the heater 1 is provided with a feed port 5, and the position of the feed port 5 can be selected according to needs. In this embodiment, the feed port 5 is arranged at the The lower part of the heater 1; the upper part of the heater 1 is provided with an air outlet 2, in this embodiment, the air outlet 2 is arranged on the top of the heater 1; material outlet 6, the position of the concentrated material outlet 6 can be selected according to needs, in this embodiment, the concentrated material outlet 6 is arranged at the bottom of the heater 1; the heater 1 is any commercially available The heater 1, its heating mode is any mode that can be realized, preferably electric heating and steam heating etc., in the present embodiment, described heater 1 is electric heater;

[0052] An evaporator 7, the evaporator 7 is provided with a steam inlet 10, the position of the steam inl...

Embodiment 2

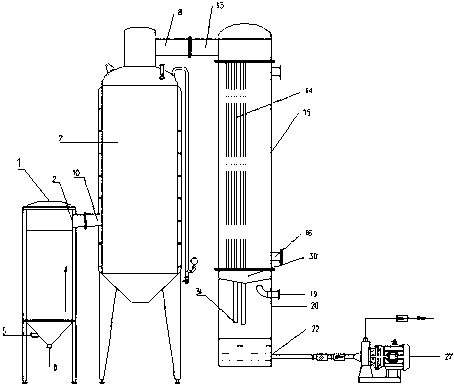

[0059] Such as figure 2 As shown, the vacuum concentrator described in this embodiment is based on the above embodiments, the drain port 22 is connected with a drain pump 27, and the condensed liquid collected in the liquid chamber passes through the drain pump 27 through the drain port 22 Discharge; the distance between the vacuum tube 19 and the outlet 31 of the liquid outlet becomes 700mm.

Embodiment 3

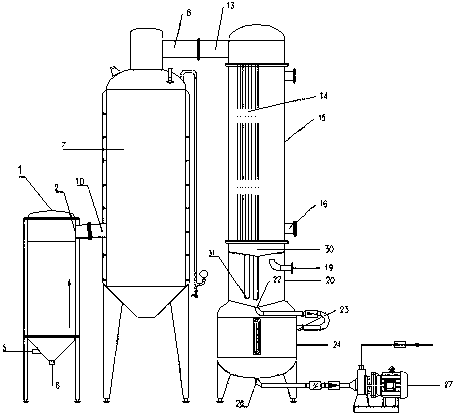

[0061] Such as image 3As shown, on the basis of the above-mentioned embodiments, the vacuum concentrator in this embodiment also includes a liquid receiving tank 24, and the liquid receiving tank 24 is arranged below the liquid collector 20. In this embodiment, The distance between the vacuum tube 19 and the liquid outlet pipe outlet 31 is set to 900mm; the bottom of the liquid collector 20 is connected to the top of the liquid receiving tank 24; the liquid receiving tank 24 is provided with a liquid inlet 23 And liquid outlet 26, in the present embodiment, described liquid inlet 23 is arranged on the top of described liquid receiving tank 24, and described liquid outlet 26 is arranged on the bottom of described liquid receiving tank 24; The discharge port 22 of the device 20 communicates with the inside of the liquid receiving tank 24 through the liquid inlet 23; the liquid outlet 26 is connected with the drain pump 27; and, the liquid collector 20 The bottom is an inverted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com