Integral garbage crushing and sorting machine and garbage disposal method thereof

A sorting machine and garbage technology, applied in chemical instruments and methods, solid separation, grain treatment, etc., can solve the problems of single-function production line of garbage treatment equipment, complex garbage treatment production line, high energy consumption environment, etc., to improve garbage treatment Efficiency, simplification of production line layout, savings in system operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

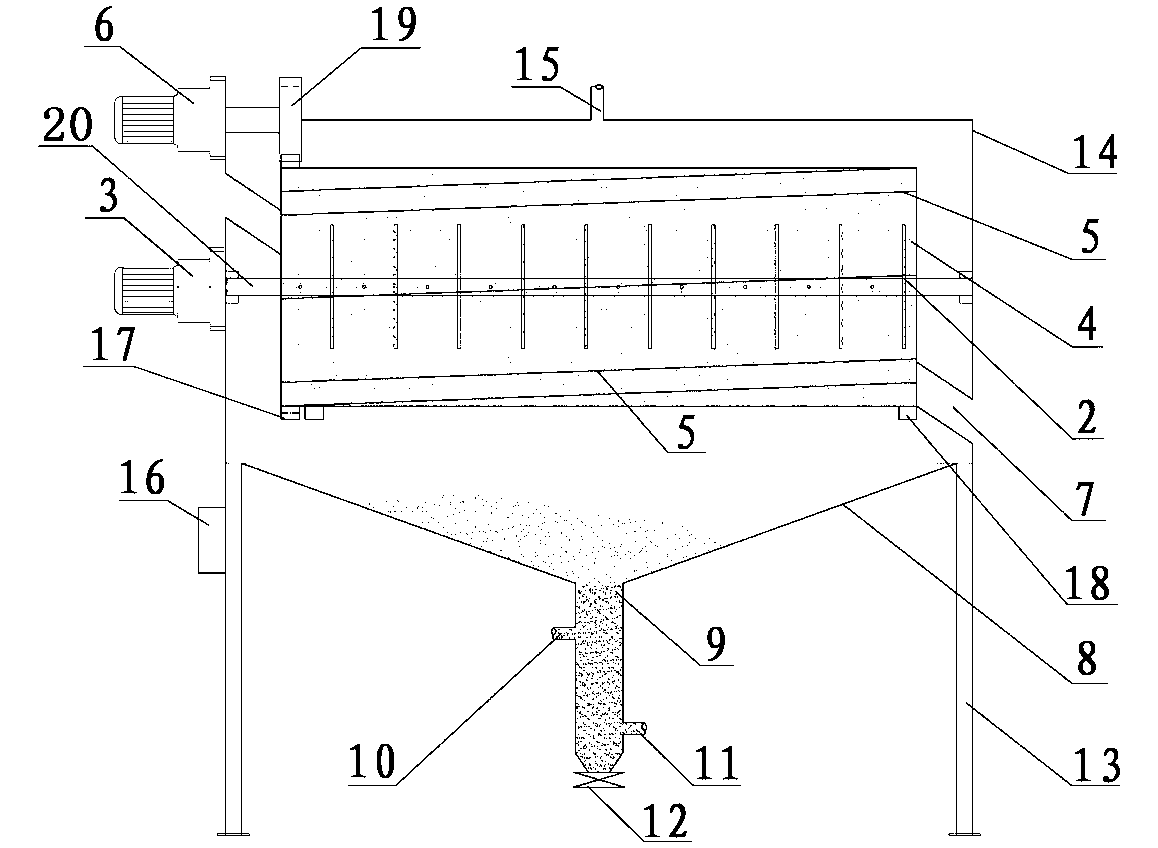

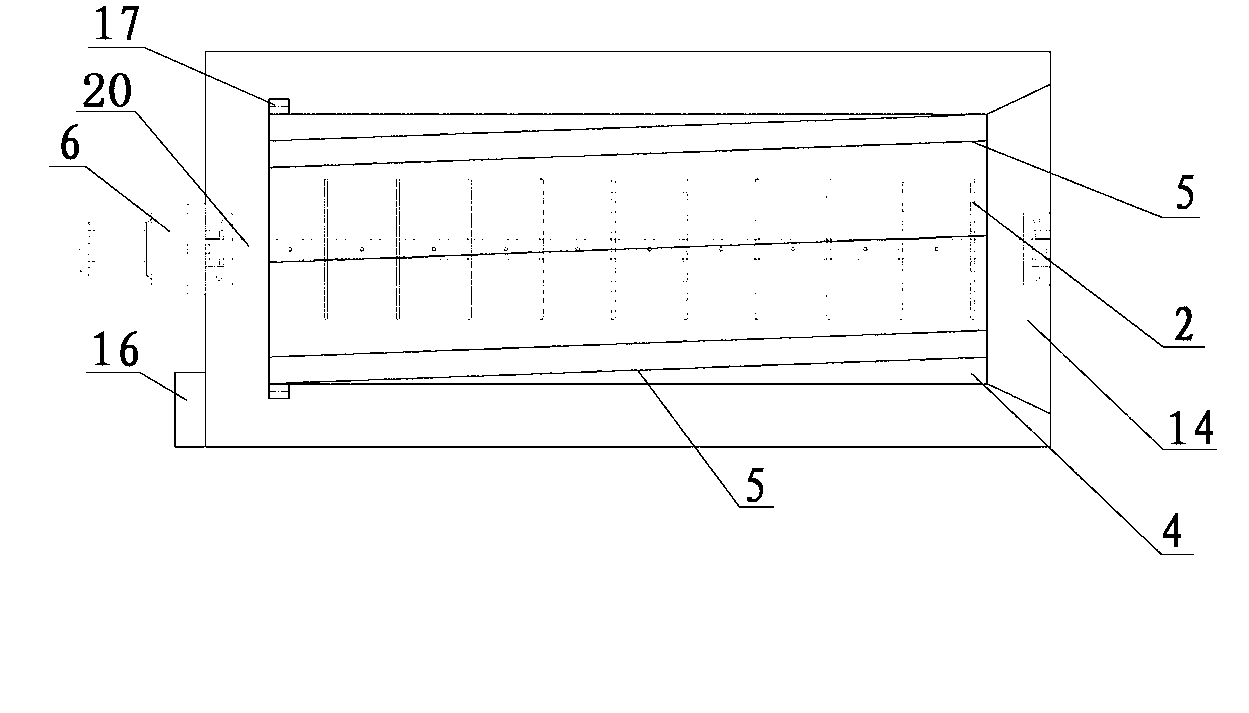

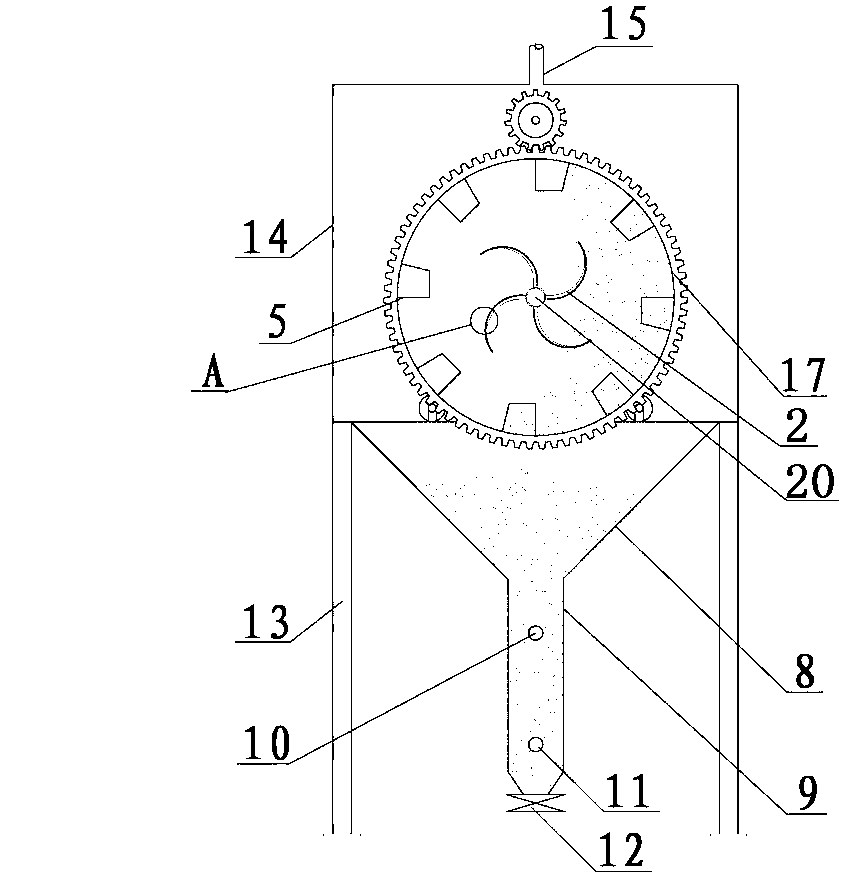

[0032] Embodiment sees specification attached Figure 1-4 As mentioned, this integrated garbage crushing and sorting machine includes a frame, a power part and a crushing cutter, and the power part includes a cutter drive motor 3 and a screen drum drive motor 6 controlled by an electric control box 16, and the screen drum The output end of the driving motor 6 drives and connects a horizontally arranged screen cylinder 4, on which screen holes are distributed, and a material guide plate 5 is distributed on the inner wall of the screen cylinder, and a ring gear is arranged on the outer periphery of the screen cylinder 4 17. The ring gear 17 is meshed with the reducer gear 19 driven by the screen drum drive motor, and the bottom of the screen drum 4 is supported by the support wheel 18 fixed on the frame 13; the cutter drive motor 3 is connected with the The central rotating shaft 20 is driven and connected, and the central rotating shaft 20 is connected to a group of crushing kn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Blockiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com