A powder metallurgy mold

A powder metallurgy and mold technology, applied in the field of powder metallurgy molds, can solve the problems affecting the quality of green compacts, uneven deformation of the mold base, uneven heating temperature, etc., and achieves a constant controllable range, fast heating speed, and uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

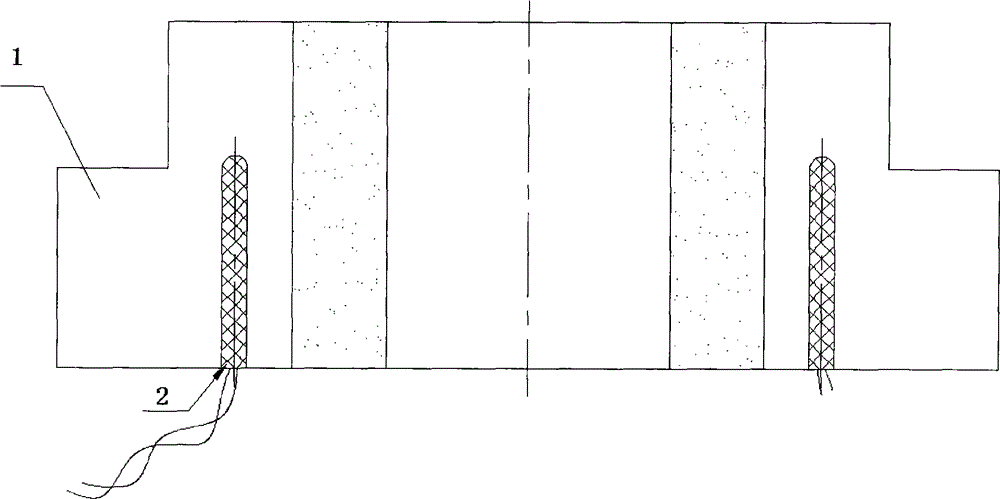

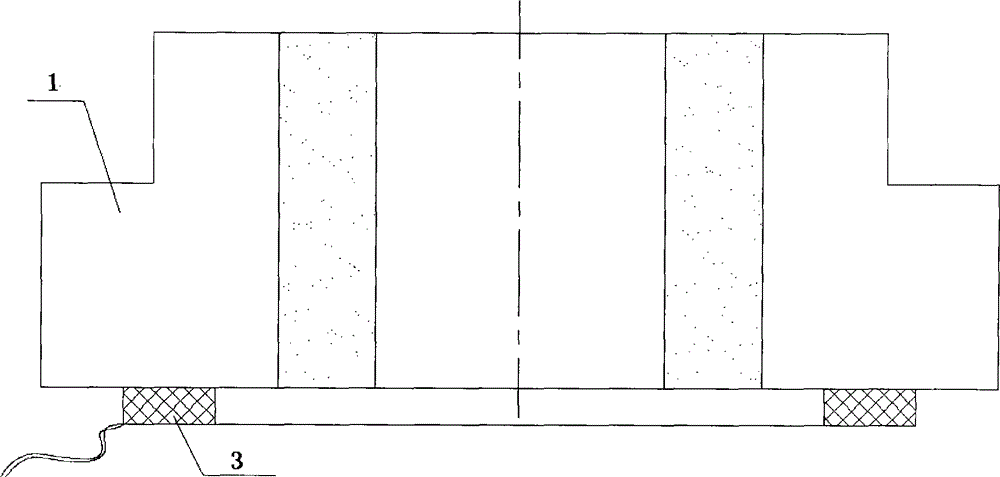

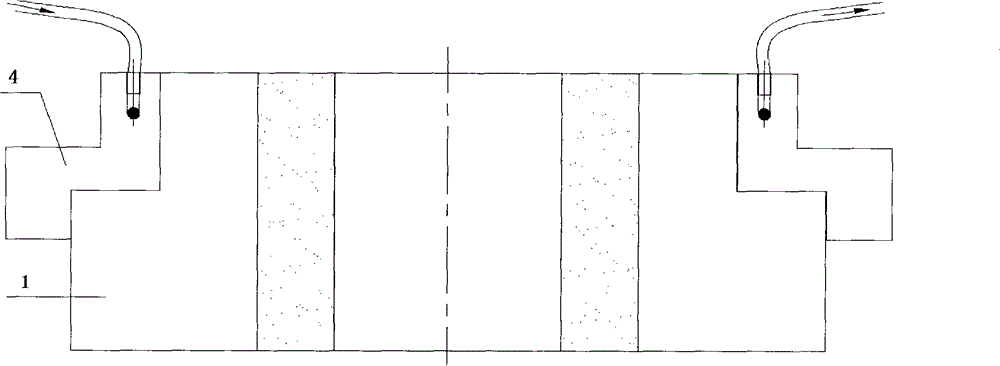

[0046] Combine below Figure 5 to Figure 9 , the present invention is further described:

[0047] Such as Figure 5 As shown, the powder metallurgy mold of the present invention includes a female mold casing 11 and a female mold core 12, and the female mold casing 11 and the female mold core 12 are in interference fit. A spiral oil groove 13 is arranged on the annular inner surface of the female mold outer casing 11, and the spiral oil groove 13 forms a thermal oil circuit with the externally connected temperature-controllable thermal oil.

[0048] The hot oil circuit also includes an oil inlet nozzle 14, an oil inlet pipeline 16, an oil outlet nozzle 15 and an oil outlet pipeline 17. The oil inlet pipeline 16 communicates with the helical oil groove 13 at the highest position. The oil outlet pipeline 17 communicates with the spiral oil groove 13 at the lowest position.

[0049] It works as follows:

[0050] The externally connected temperature-controllable hot oil flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com