High wear-resistant alumina zirconium copper gold iron tailings pulp valve

A technology of alumina and iron tailings, applied in valve details, valve devices, sliding valves, etc., can solve the problems of not being able to ensure the normal use of the valve in time, damage to the valve plate and valve lining, and inability to lift the valve plate. The effect of easy maintenance and replacement, easy replacement, and enhanced pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

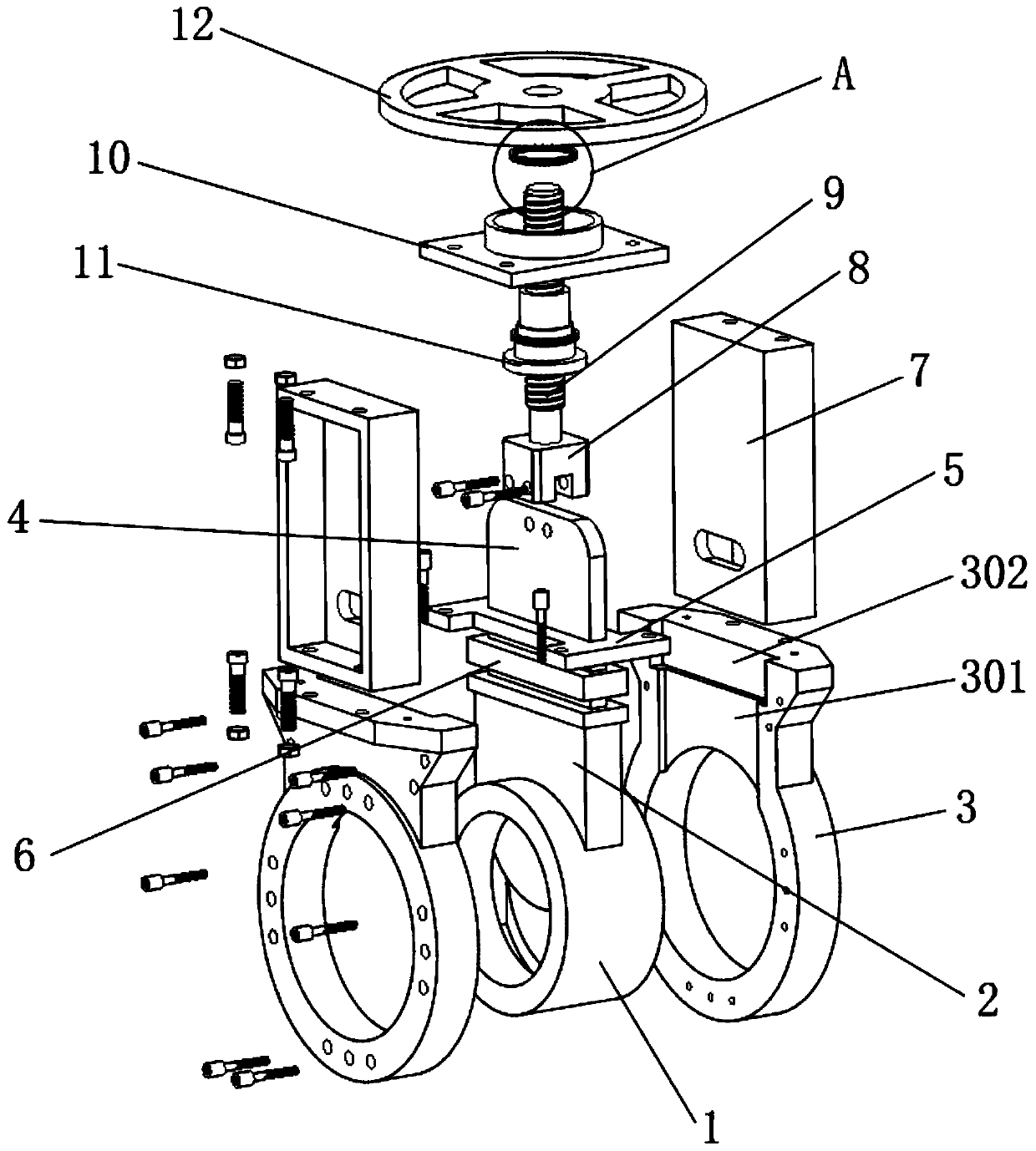

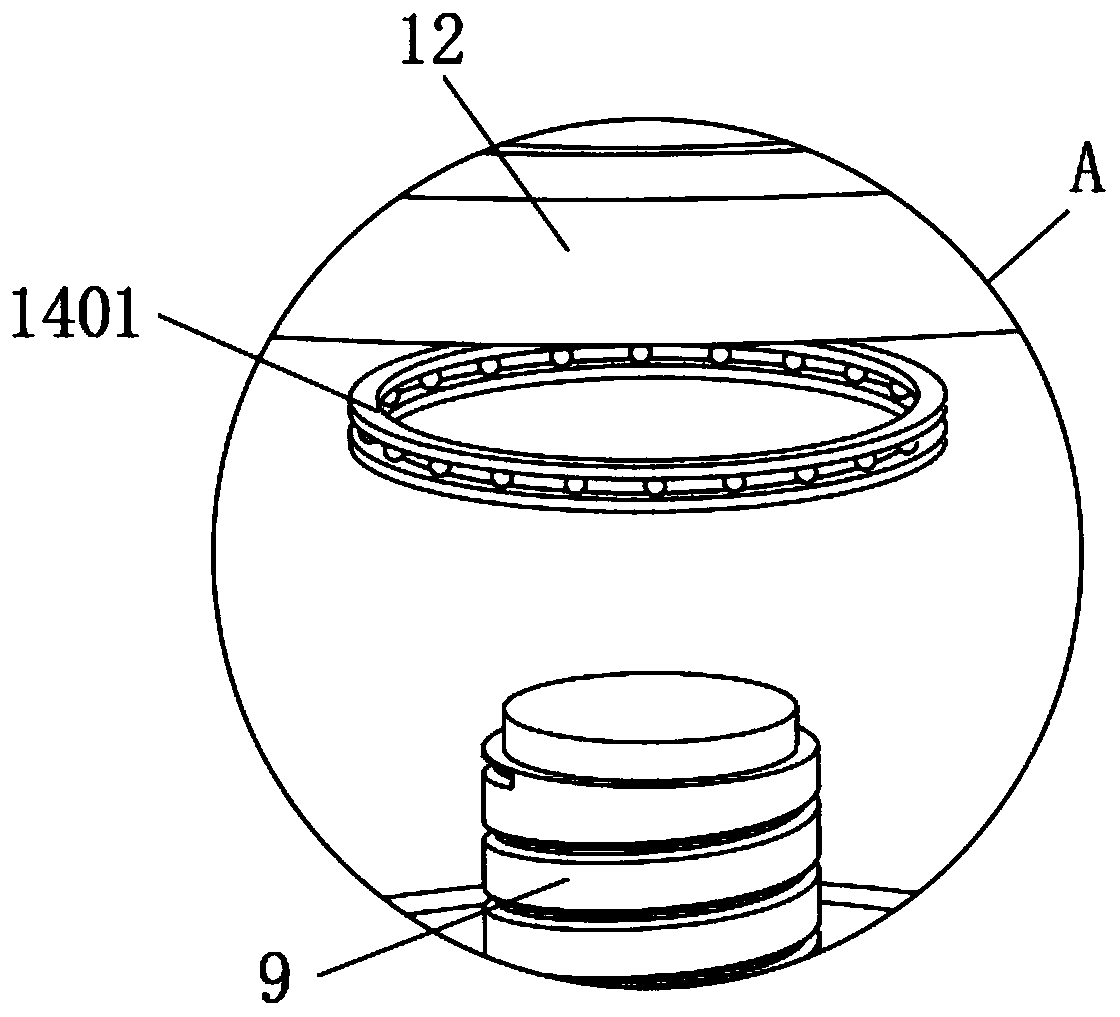

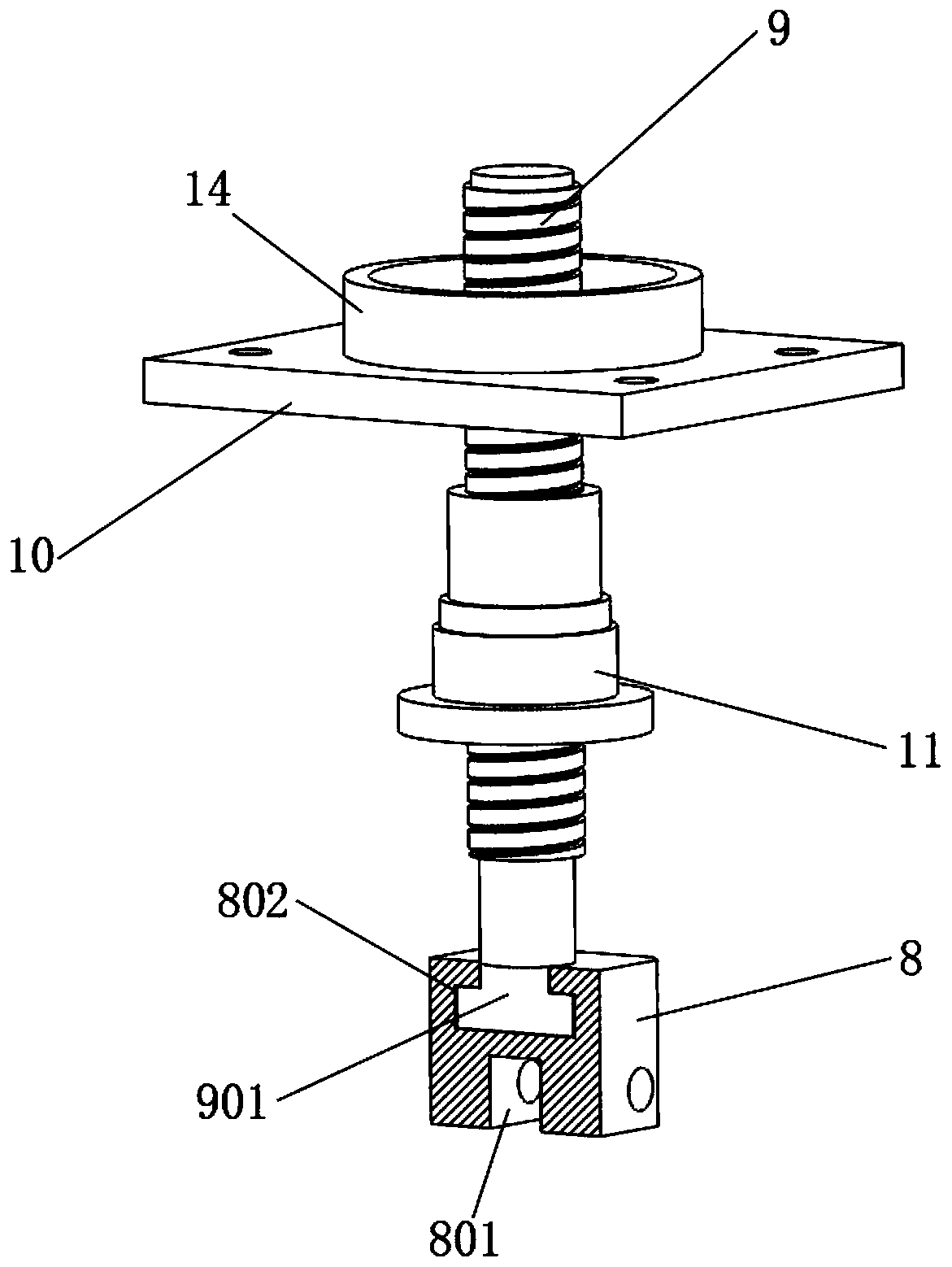

[0029] The embodiment of the present invention provides a high wear-resistant alumina zirconium copper gold iron tailings slurry valve, such as Figure 1-6 As shown in the figure, it includes a valve liner body 1, a valve body body 3 and a valve plate body 4. The number of valve body bodies 3 is two groups. After the two groups of valve body bodies 3 are closed, the valve liner body 1 can be fixed inside the valve body. The plate main body 4 slides inside the valve lining main body 1. The outside of the valve lining main body 1 is sleeved with the packing main body 6 and the gland main body 5. The gland main body 5 is fixedly connected to the upper surface of the two groups of valve body main bodies 3 by bolts. The top of the plate main body 4 is provided with a lifting mechanism. This valve is a full-diameter cut-off valve. After opening, the valve plate main body 4 is completely lifted to the inside of the valve cavity, and the valve plate main body 4 does not directly contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com