Automatic intermittent cycle worktable

A workbench and automatic technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to adjust, difficult indexing accuracy, high indexing accuracy, etc., to reduce labor force, strong applicability, Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 19 , is the automatic intermittent cycle workbench of the present invention, the automatic intermittent cycle workbench is an up and down cycle structure,

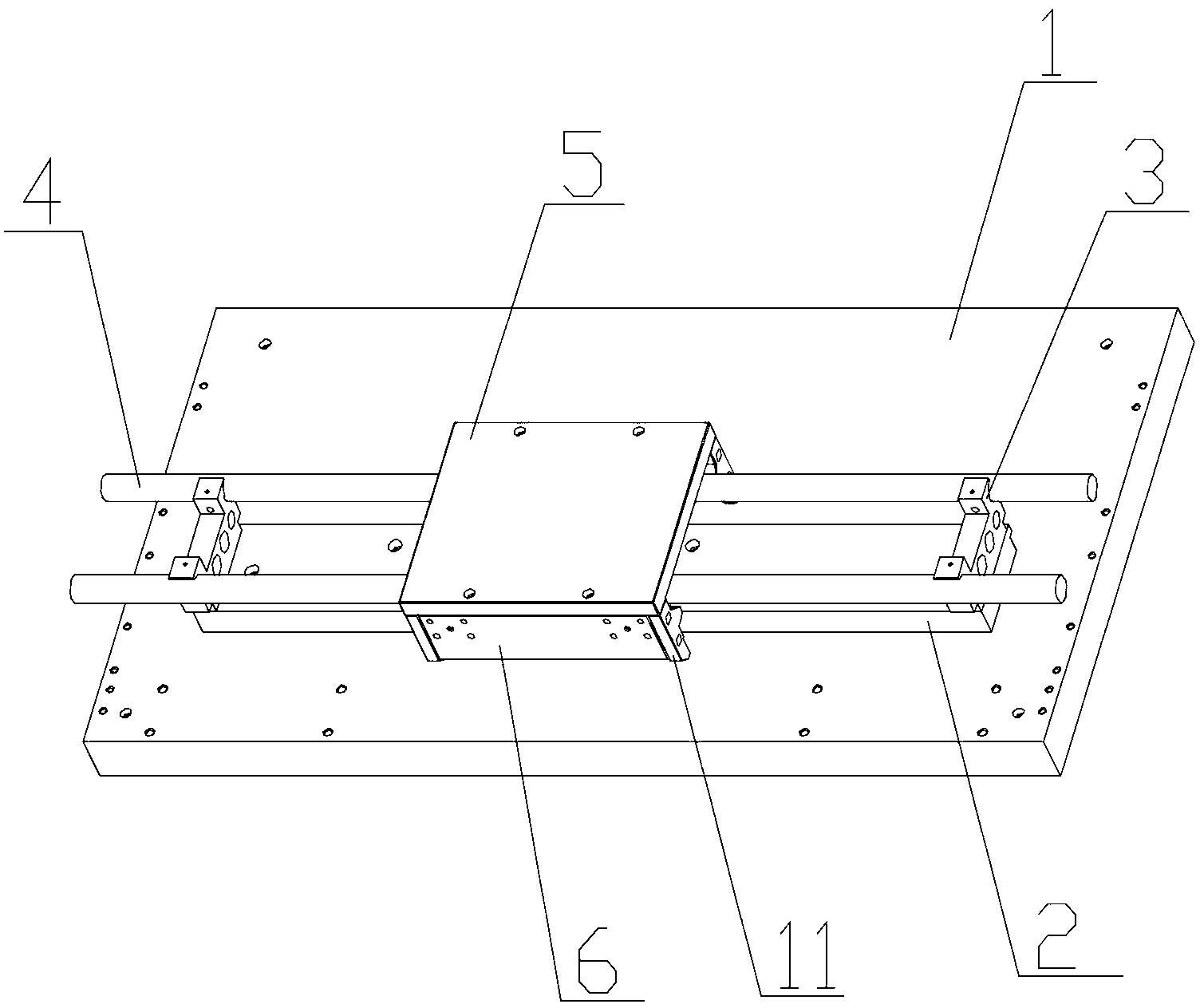

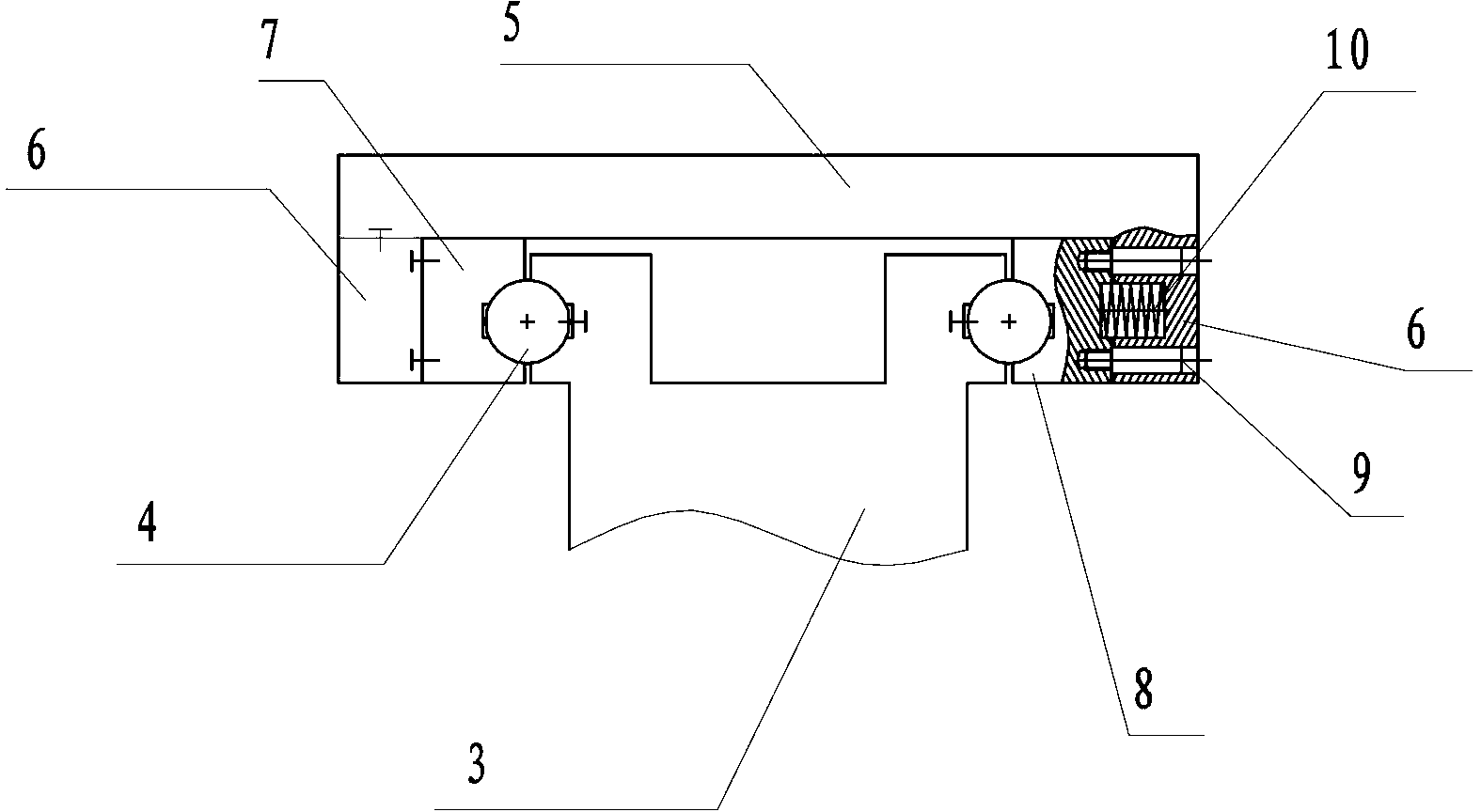

[0040] Including guide rail and sliding table combination device 100, pneumatic pulling and pushing device assembly 200, working sliding table movement limit device 300, sliding table return device 400 and upper and lower track running device 500, each guide rail and sliding table combination device 100 are equipped with a pneumatic pulling and pushing device assembly 200 and a working sliding table movement limit device 300, and the pneumatic pulling and pushing device assembly 200 is used to control the movement of the sliding table of the guide rail and sliding table combination device 100 on the guide rail. Movement; the moving limit device 300 of the working slide table is used to control the limit when the slide table of the guide rail and slide table combination device 100 moves to the working...

Embodiment 2

[0063] Such as Figure 15 , is another scheme of the automatic intermittent cycle workbench described in the present invention, the automatic intermittent cycle workbench is a planar cycle structure, adopts an even number of guide rail and slide table combination devices 100 arranged in parallel to each other, and is installed on the guide rail and slide table The lower pneumatic pulling and pushing device assembly 200 of the combination device 100 and the working sliding table movement limit device 300 together form a horizontal track device, and the two ends of the horizontal track device are respectively connected with vertical tracks that can be connected to it The device 600 forms a docked horizontal circular revolving track, and the vertical track device includes a horizontal slide table and a guide rail conveying device 601 and a secondary guide rail device 602, and a secondary guide rail device 602 is fixedly installed on the horizontal slide table and the guide rail co...

Embodiment 3

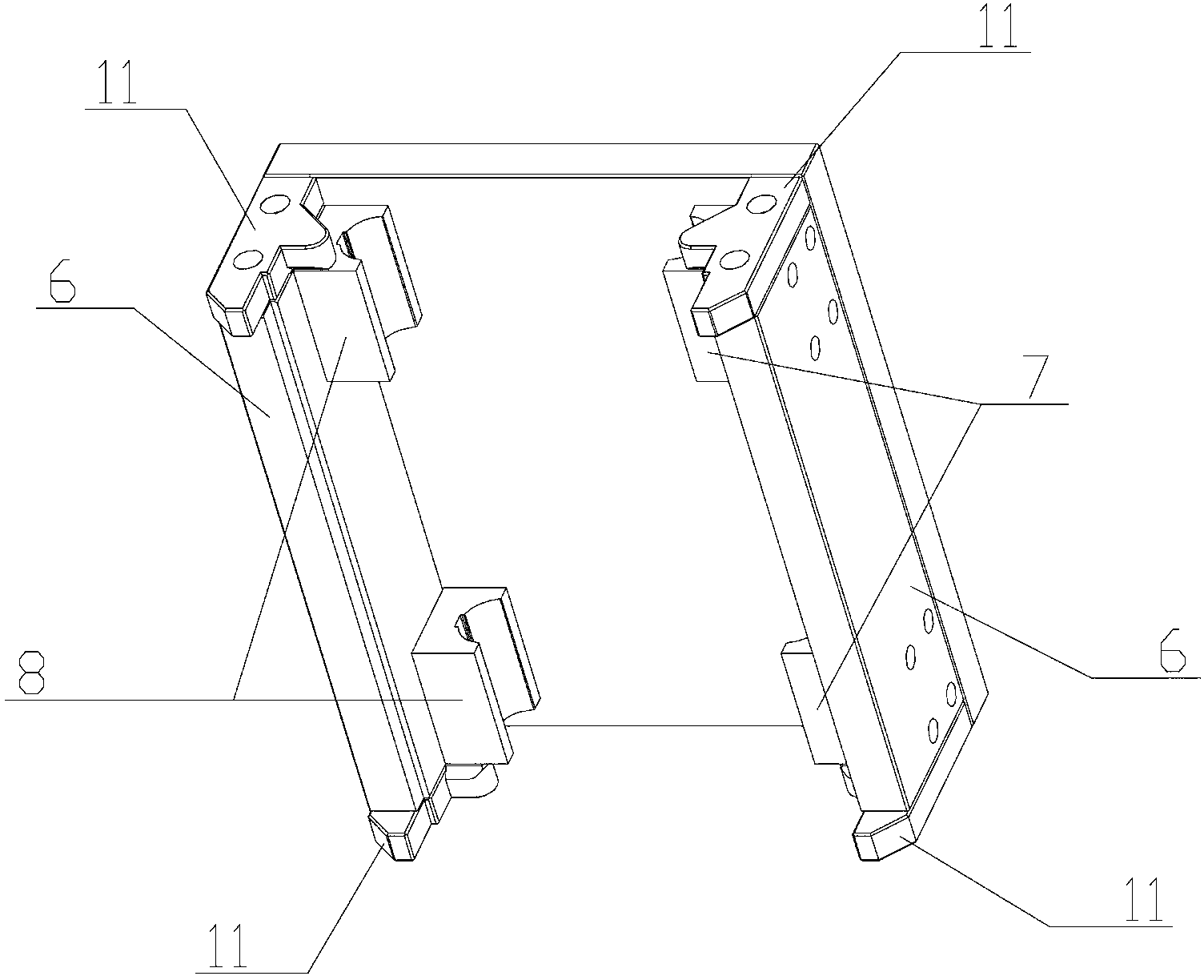

[0068] Such as Figure 17 and 21 , is another scheme of the automatic intermittent cycle workbench described in the present invention, the described automatic intermittent cycle workbench is a device when a single workbench works in an independent cycle, and several groups of guide rail and sliding table combination devices 100, Pneumatic pulling and pushing device assembly 200, working sliding table movement limiting device 300, wherein guide rail and sliding table combination device 100, pneumatic pulling and pushing device assembly 200, working sliding table moving limiting device 300 are basically the same, the difference The position is to first confirm the groove of the fixed block 17 on the pneumatic pulling and pushing device assembly, which is located at the top during installation, and then remove a positioning block 11 close to the cylinder 12 from the slide table on the same side of the fixed block 17 , the positioning block 11 is used as a protruding part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com