Pneumatic composite clamping device

A clamping device and clamping technology, applied in the directions of positioning device, clamping, support, etc., can solve the problems of difficult operation, high cost, complicated device, etc., and achieve the effects of low processing and manufacturing cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

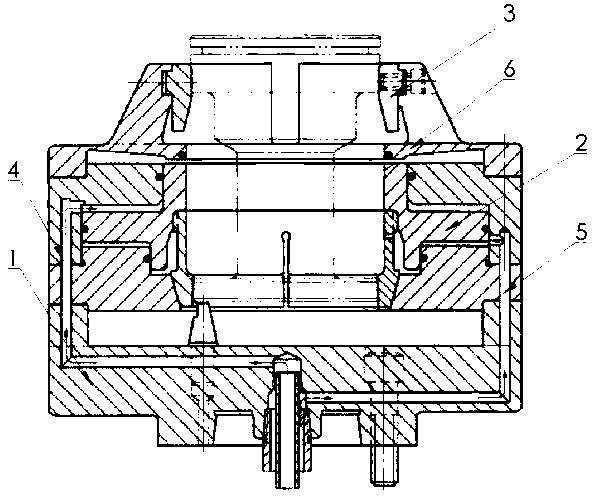

[0011] like figure 1 As shown, the present invention provides a pneumatic composite clamping device, including a base 1 provided with a cylinder, a piston 2 cooperating with the cylinder, a jaw 3 cooperating with the piston 2, and two limit positions of the piston 2 respectively. There are six claws for clamping air passage 4 and releasing air passage 5, which are evenly installed on the prestressed metal sheet 6. The metal sheet 6 is normally concave downwards, so that the claws 3 on its upper surface are in a clamping position. state, the upward limit state of the piston 2 is to squeeze the metal sheet 6 to make the metal sheet 6 protrude upwards to reach another stable state, thereby releasing the claw 3 .

[0012] The above is only the preferred embodiment of the present invention, it should be pointed out that for those skilled in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com