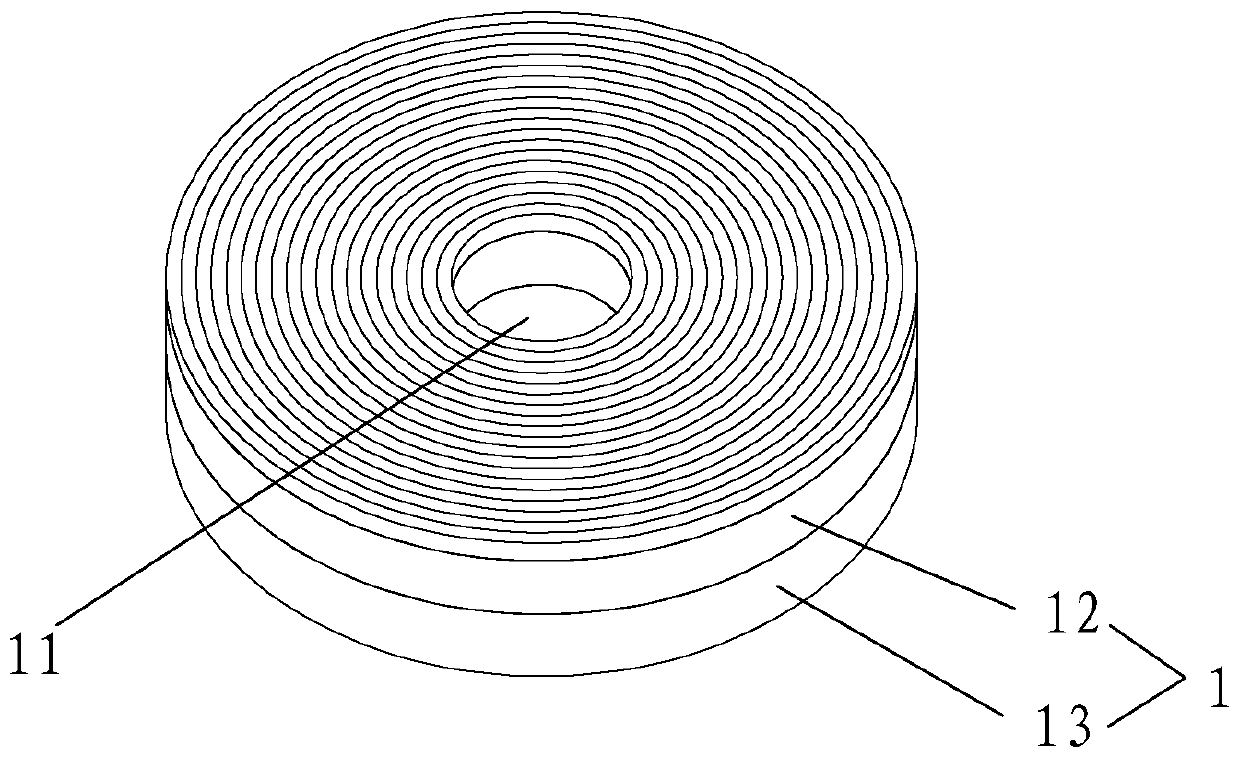

Pyramid Grinding Disc

A pyramid and grinding disc technology, applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of unsuitable crystal fine grinding, shortened service life, short service life, etc., to achieve long service life, stable cutting efficiency and safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

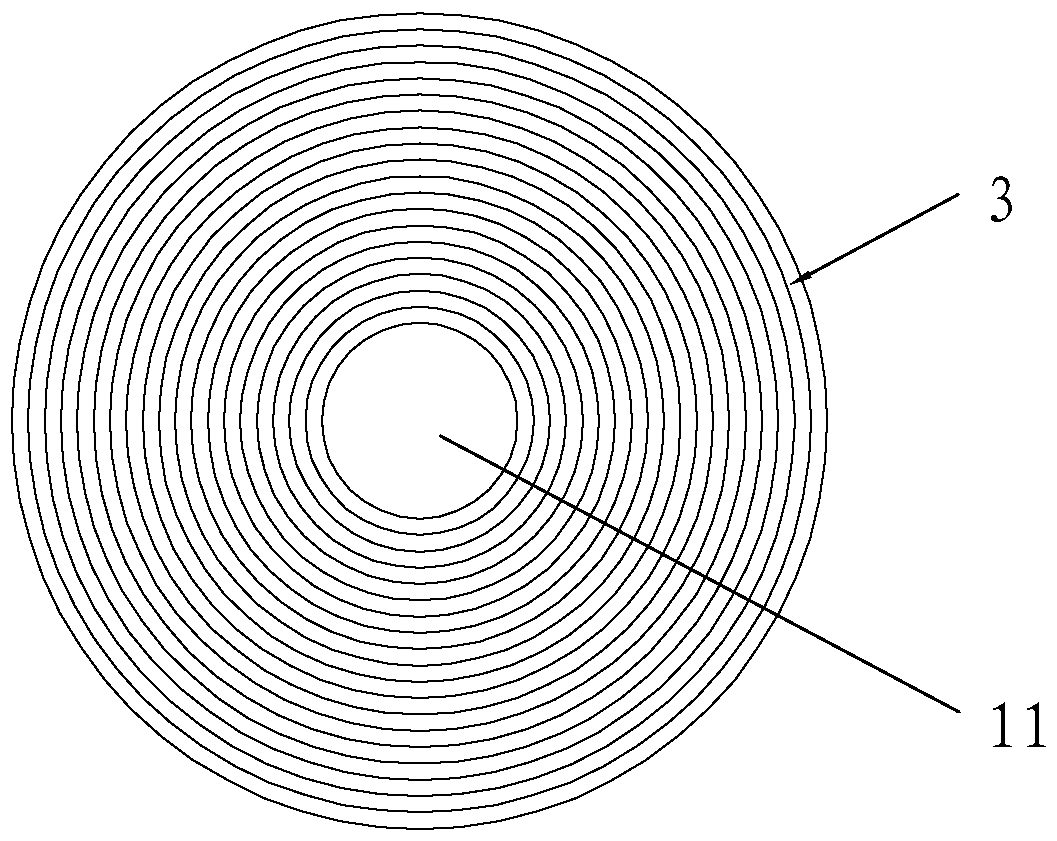

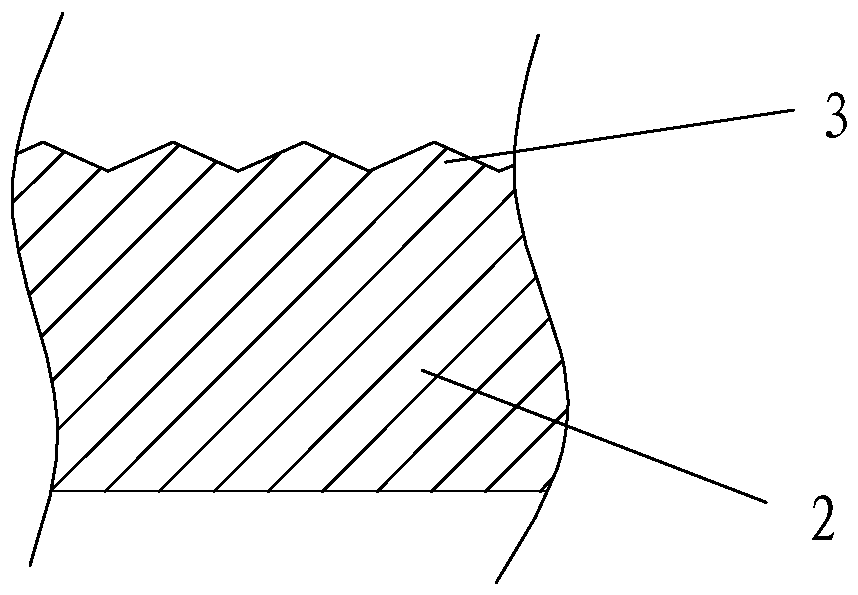

Image

Examples

Embodiment 1

[0022] Pyramid grinding disc, which includes 60% to 80% (by weight) of diamond powder, and the balance is non-diamond nano-scale polishing material, wherein the non-diamond nano-scale polishing material is one of alumina, cerium oxide, and silicon carbide. Several kinds of mixtures with resin, diamond micropowder and non-diamond nano-scale polishing materials have a mesh number of 600-5000 mesh. When the pyramid grinding disc of this embodiment is processed, the abrasives are mixed and evenly distributed to obtain stable cutting efficiency and longer The service life of diamond micropowder and aluminum oxide, cerium oxide and silicon carbide can be finely ground the crystal without damaging the processed material, no fragments, no scratches, better stability and safety, and due to the diamond micropowder and Aluminum oxide, cerium oxide, and silicon carbide have stable chemical properties, so the pyramid grinding disc of the present invention performs well when used in conjunct...

Embodiment 2

[0028] The difference between this embodiment and the first embodiment is that the non-diamond nanoscale polishing material is cerium oxide instead of aluminum oxide, and the purity of cerium oxide is above 98%. Other technical features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0030] The difference between this embodiment and the first embodiment is that the non-diamond nanoscale polishing material is silicon carbide instead of aluminum oxide, and the purity of silicon carbide is above 98%. Other technical features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com