electrical tools

A technology for power tools and power components, applied in the field of impact power tools, can solve the problems of large friction resistance of the output shaft, low production cost, high manufacturing and processing level, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

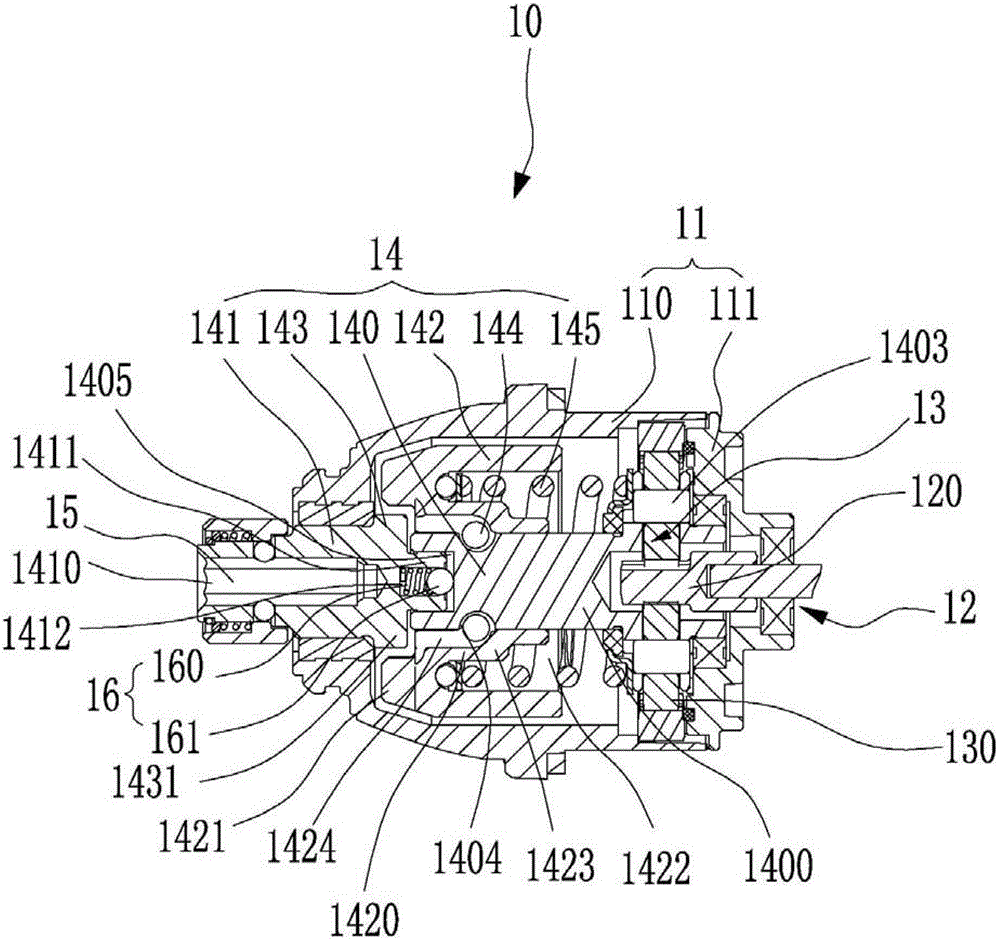

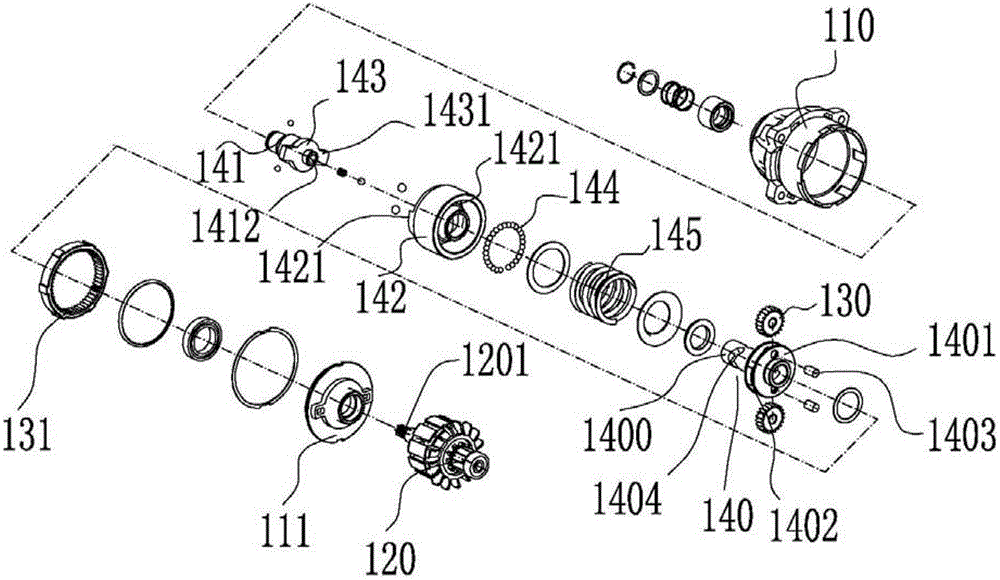

[0022] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

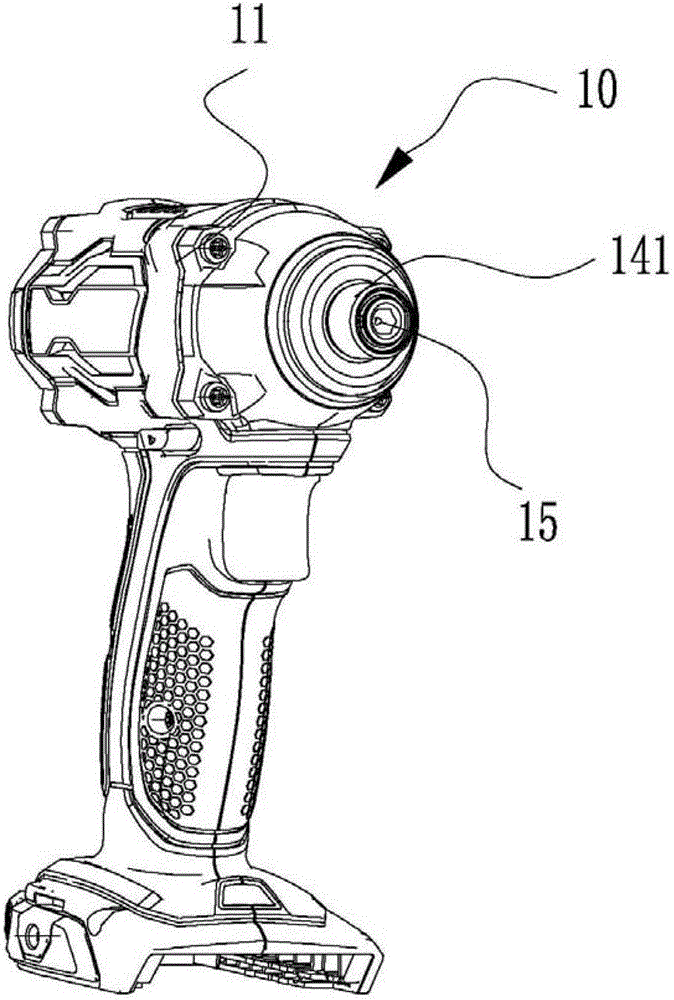

[0023] Please refer to figure 1 and figure 2 The electric tool 10 in the first embodiment of the present invention includes a housing 11, a power component 12, a speed reduction mechanism 13, an impact mechanism 14, an actuator 15 and a shock absorbing mechanism 16. In this embodiment, an impact screwdriver is used as an example The electric tool 10 will be described in detail.

[0024] The casing 11 includes a front casing 110 and a rear casing 111 , and the front casing 110 and the rear casing 111 are screwed together. It can be understood that the front case 110 and the rear case 111 can also be connected by clamping or other connection methods, as long as the connection method can connect the front case 110 and the rear case 111 as a whole and is easy to disassemble, it should belong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com