Serial number code spraying machine

A serial number and coding technology, which is applied in the field of inkjet printers, can solve the problems of inaccurate positioning of inkjet printers, inaccurate and inconvenient secondary resets, and difficult cleaning, etc., to achieve color fading, accurate resets, and stable negative pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

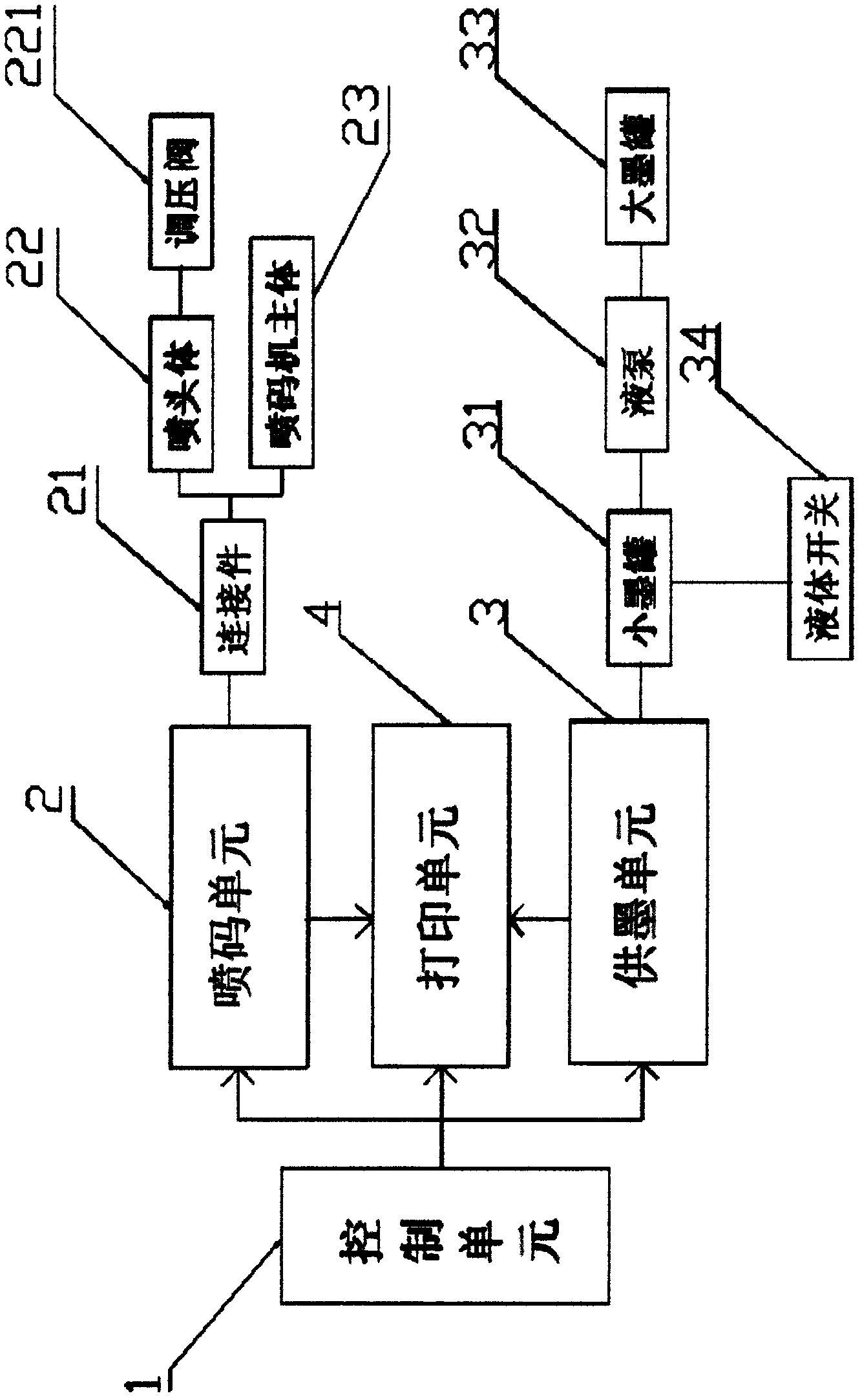

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] see figure 1 , a serial number jetting machine, comprising a coding unit 2, an ink supply unit 3, a printing unit 4 and a control unit 1, wherein: the coding unit 2, the ink supply unit 3, and the printing unit 4 are electrically connected to the control unit 1 The inkjet coding unit 2 is composed of a nozzle body 22 and the inkjet printer main body 23 tightly connected by a connecting piece 21; the ink supply unit 3 includes a large ink tank 33, a small ink tank 31, a liquid pump 32 and a liquid switch 34. When printing, the characters or graphics to be printed are processed by the main board of the computer, and a series of electrical signals are output to the intelligent micro solenoid valve through the output board in the control unit 1. The valve opens and closes quickly, and the ink relies on the internal constant pressure to form ink dots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com