How to make embossed fabric

A production method and embossing technology, applied in the post-processing of printing, printing, printing device, etc., can solve the problems of unsatisfactory aesthetic requirements, monotonous three-dimensional levels, single effect, etc., achieve rich three-dimensional levels, novel effects, and improve aesthetics and the effect of difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

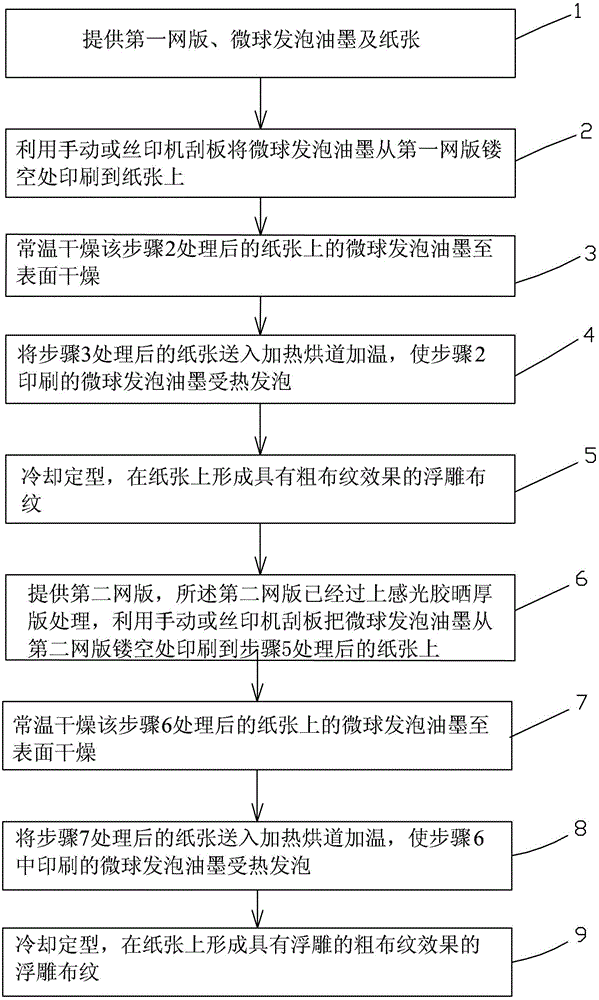

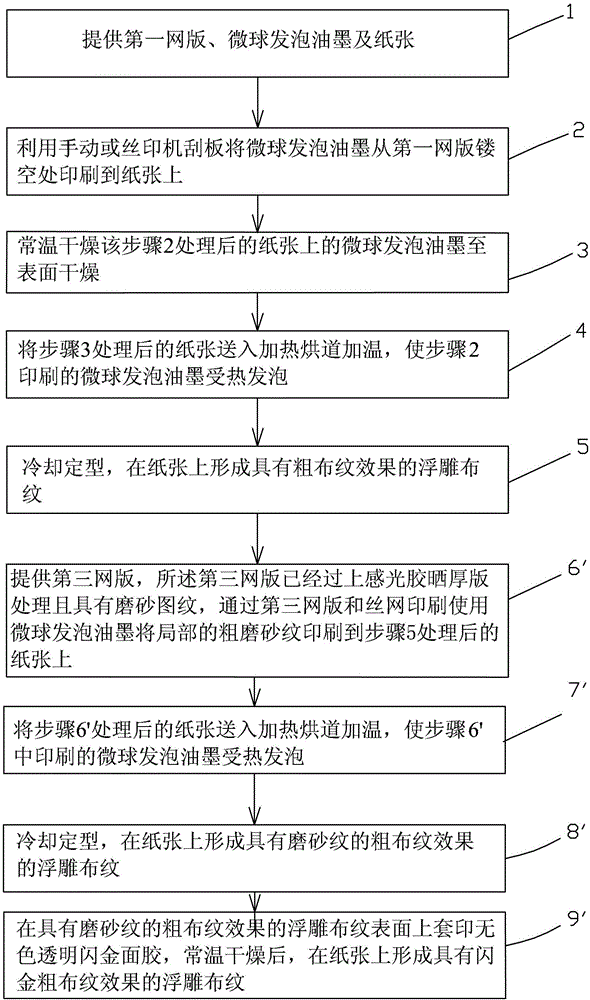

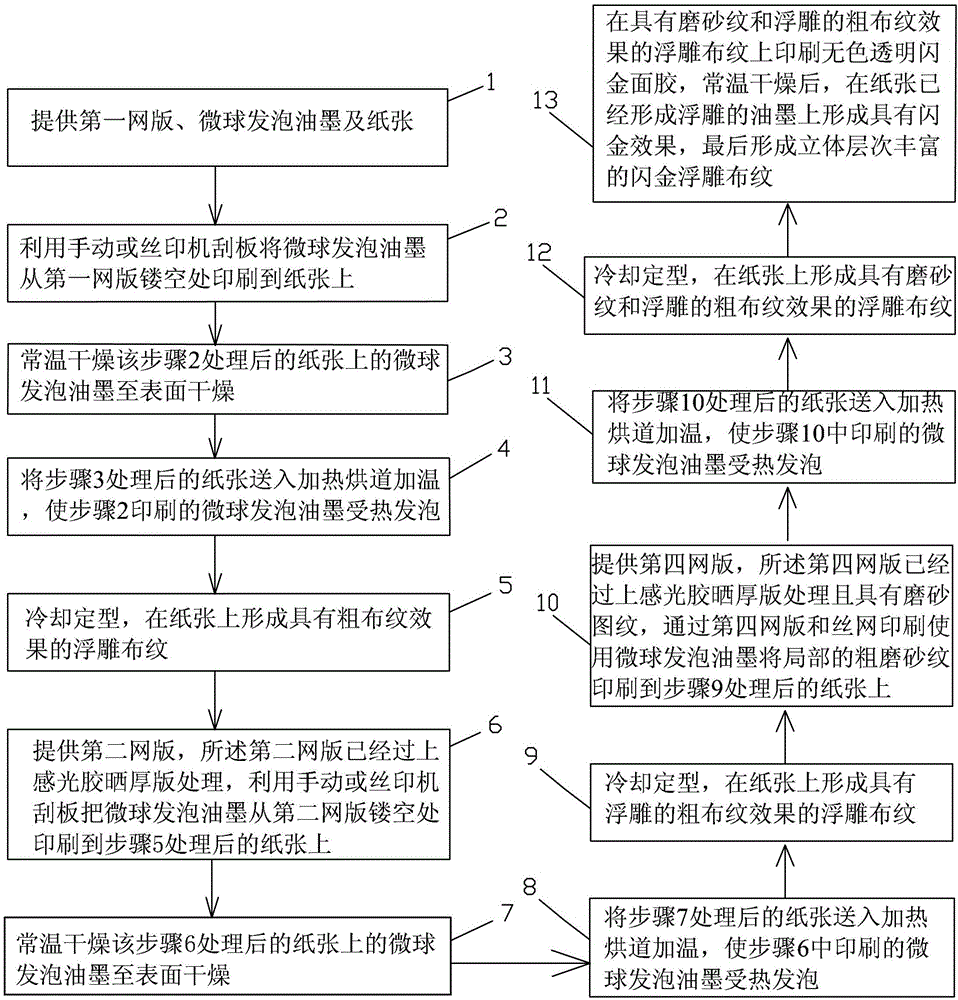

[0042] Such as figure 1 As shown, the first preferred embodiment of the method for making embossed cloth pattern of the present invention includes:

[0043] Step 1, providing the first screen, microsphere foamed ink and paper.

[0044] In the first preferred embodiment, the mesh of the first screen is 42T, and the setting range of the mesh of the first screen in actual production can be 24T-60T, so that the amount of ink is moderate, and a cloth pattern of about 1 mm can be formed, which can Choose according to product needs.

[0045] The first screen plate has not been processed with photosensitive glue and printing plate, or only some parts have been processed with photosensitive glue and printing plate. The first preferred embodiment is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com