Compensated single-trailing-arm hydraulic driving hanging system for engineering vehicle

An engineering vehicle and active suspension technology, which is applied in the direction of vehicle components, suspensions, elastic suspensions, etc., can solve the problems that engineering vehicles cannot meet the obstacle-crossing ability and the space of the suspension system is limited, so as to improve the field passing ability and The effect of working ability, easy adjustment and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

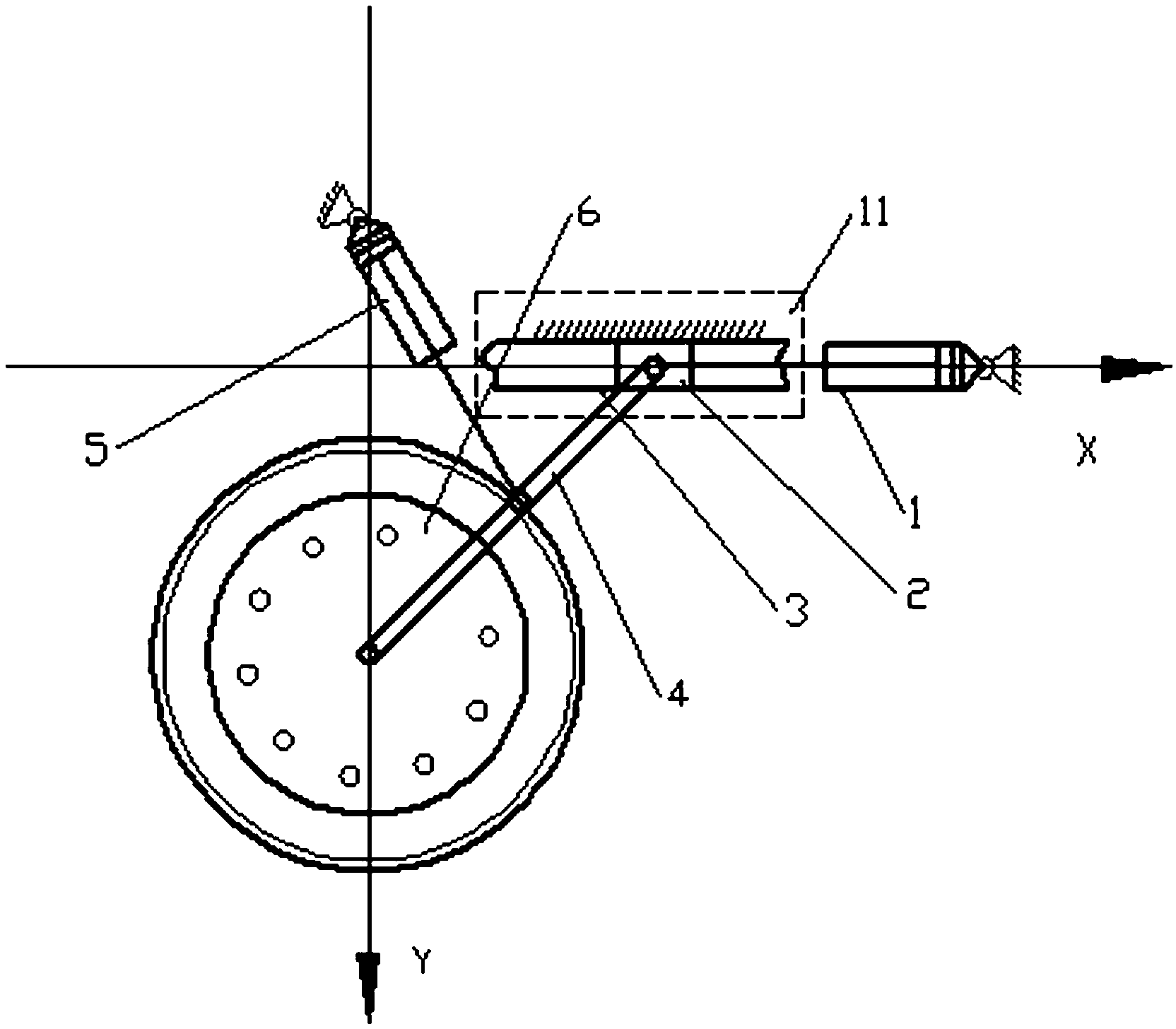

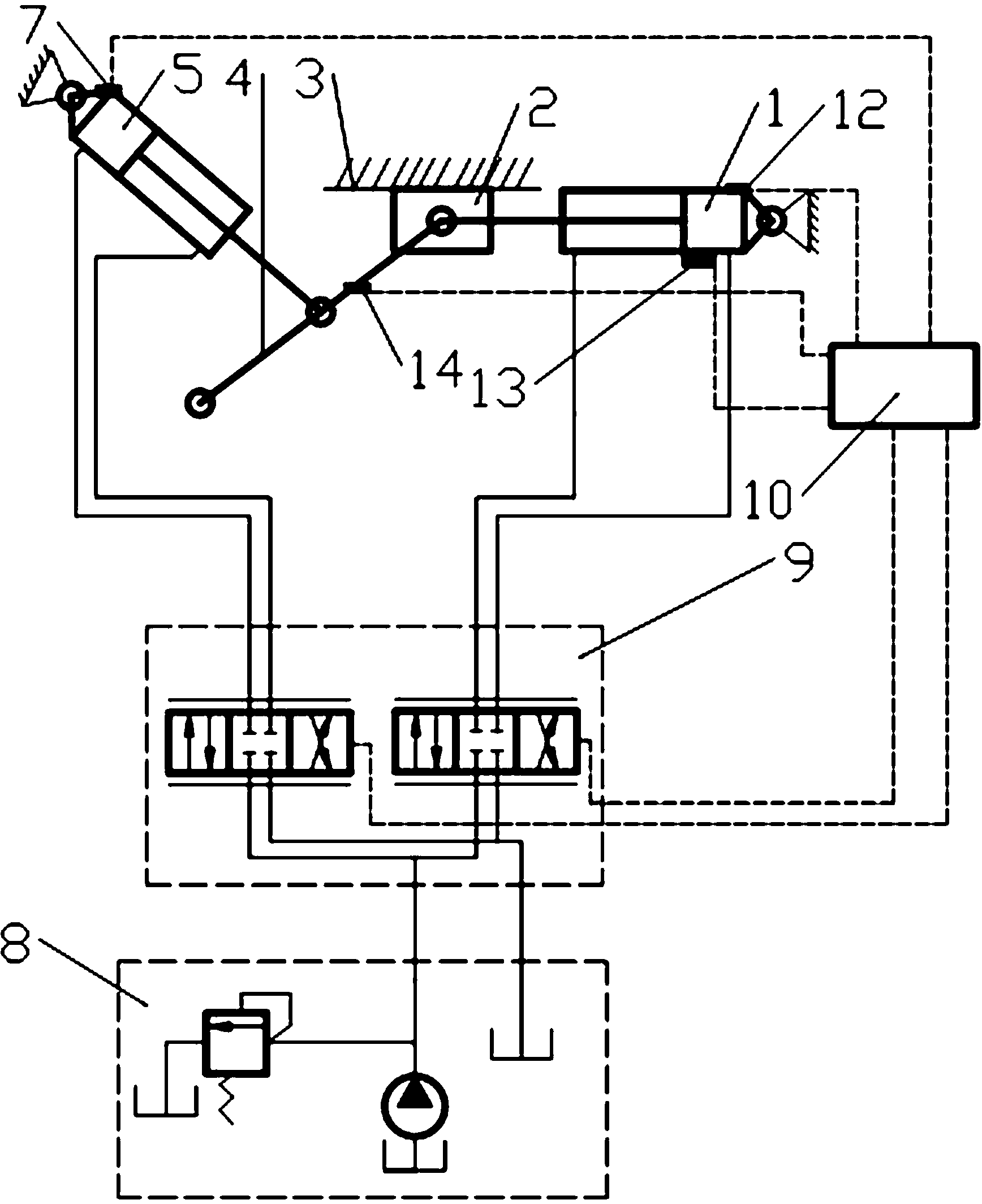

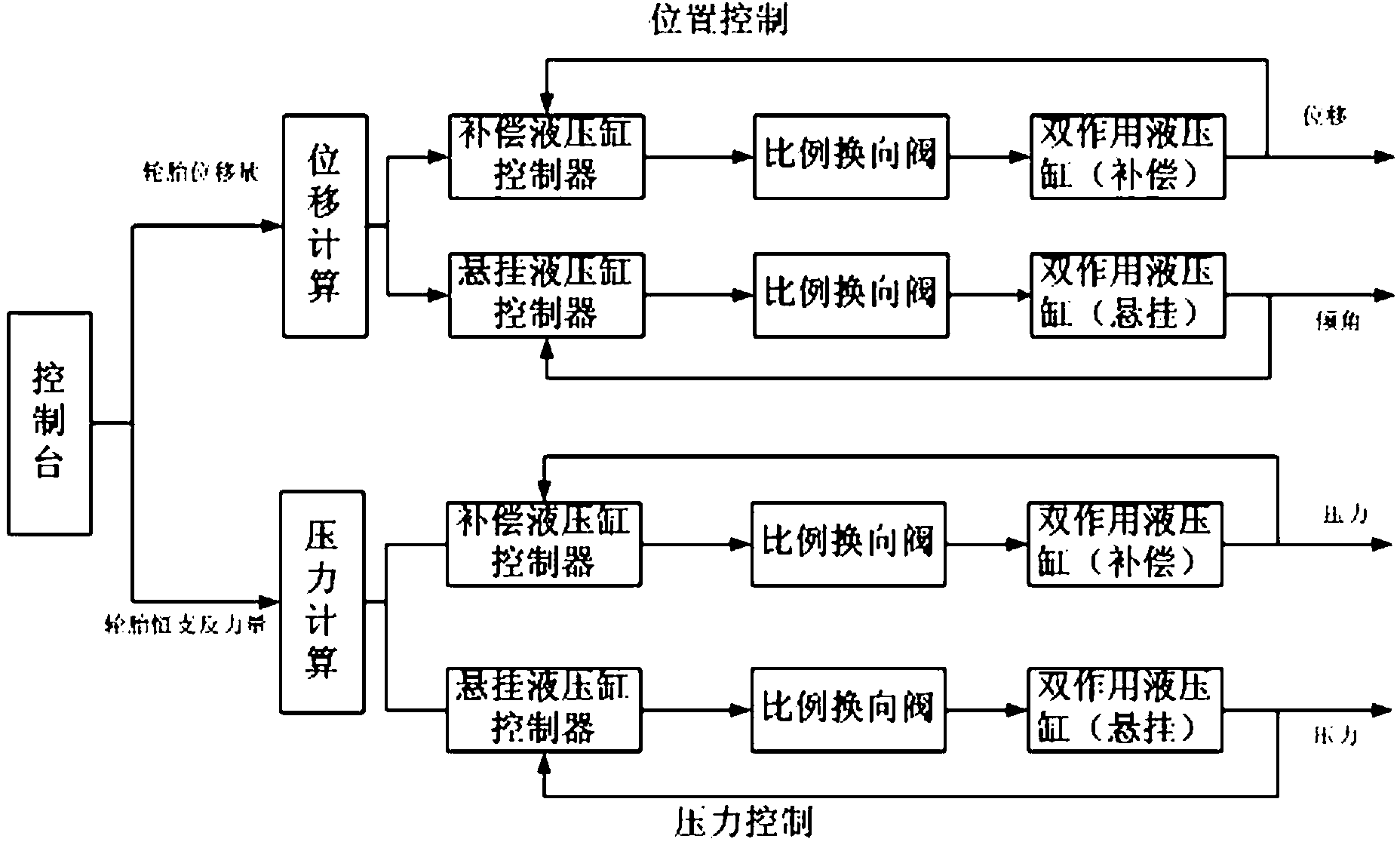

[0015] figure 1 , 2 It is an embodiment disclosed by the present invention. This engineering vehicle compensation type single trailing arm hydraulic active suspension system includes a compensation hydraulic cylinder 1 , a suspension hydraulic cylinder 5 , a hydraulic control valve 9 and a constant pressure hydraulic oil source 8 . One end of the suspension arm 4 of the compensated single trailing arm hydraulic active suspension system of engineering vehicles is connected to the wheel side drive system 6, and the other end is connected to the compensation slider 2 of the lateral displacement compensation mechanism 11, and the compensation slider 2 is connected to the compensation hydraulic cylinder 1 , the compensation hydraulic cylinder 1 is connected with a hinge fixed on the vehicle body. The middle part of the suspension arm 4 is connected with a suspension hydraulic cylinder 5, and the suspension hydraulic cylinder 5 is connected with a hinge fixed on the vehicle body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com