Integrated crushing buffer device

An integrated, buffer technology, applied in the direction of railway vehicle wheel guards/bumpers, transportation and packaging, railway car body parts, etc., can solve the problems of occupation, large longitudinal space, unfavorable coupler design, etc., and achieve large energy absorption capacity, simple and reliable structure, and the effect of saving vertical space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

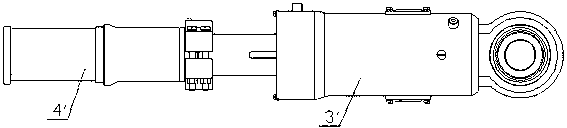

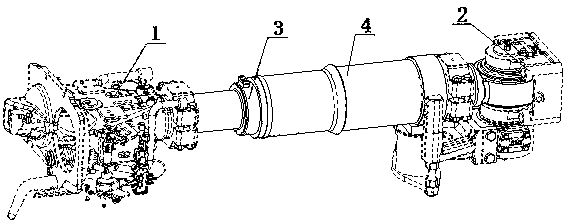

[0015] An integrated buffer crushing device, which is installed between the coupler coupling system 1 and the installation suspension system 2 of the hook buffer device. The device includes a buffer 3 and a crushing pipe 4. The inside of collapse tube 4.

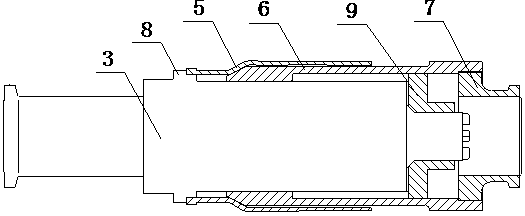

[0016] The above-mentioned crushing tube 4 includes a deforming tube 5 and a pressurizing tube 6 connected with the deforming tube 5. The shell of the buffer 3 is set in the deforming tube 5, and its end is connected with the pressurizing tube 6. The other end is connected with a flange interface 7 .

[0017] When the crushing tube 4 works, in order to deform the deforming tube 5 , the buffer housing is provided with a limiting block 8 for limiting the crushing tube, and the limiting block 8 is arranged at the inlet end of the deforming tube 5 .

[0018] During the deformation process of the deformation tube 3, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com