Equipment for producing capsule filter rods

A technology of capsules and filter rods, which is applied in applications, e-liquid filter elements, loading/unloading, etc. It can solve the problems of unsuitable composite filter rods and the inability to accurately control the insertion position of capsules, achieving simple structure and high yield , to avoid the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

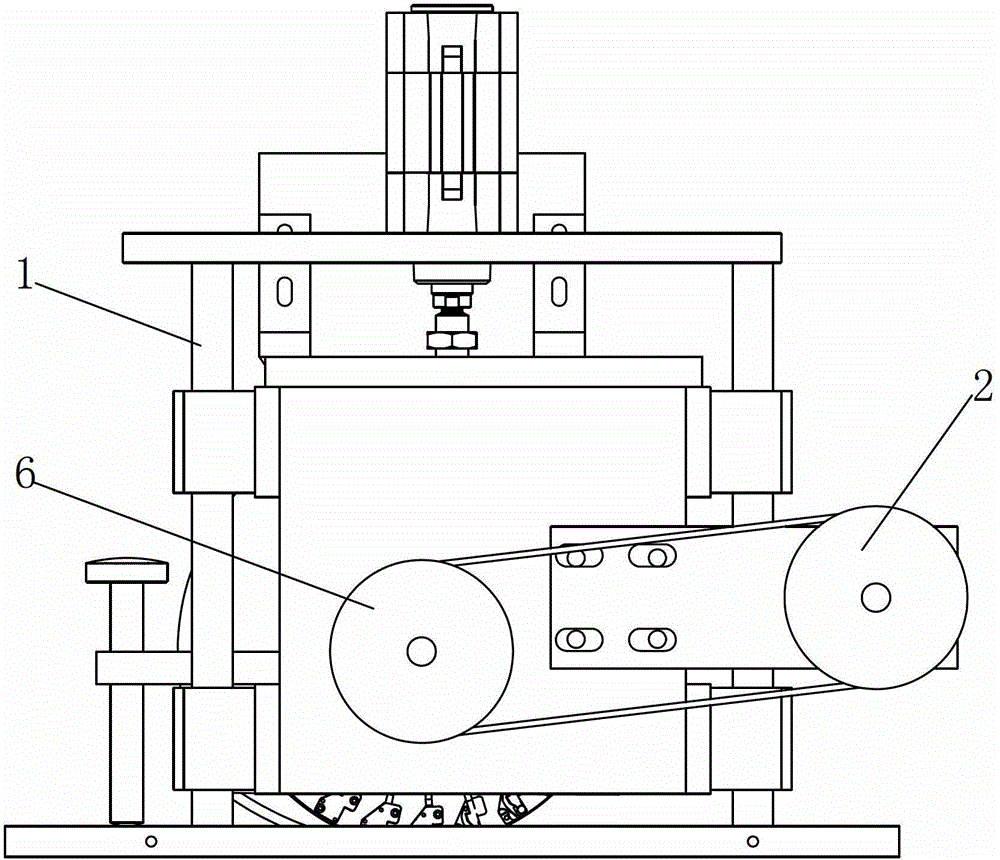

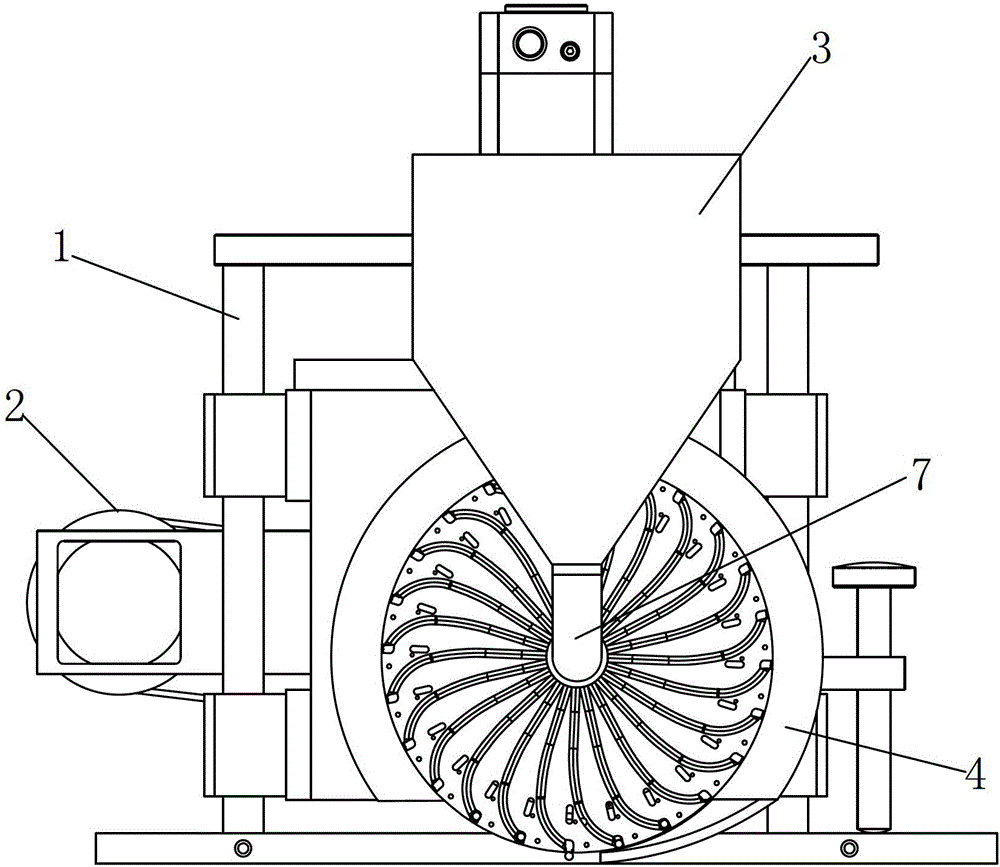

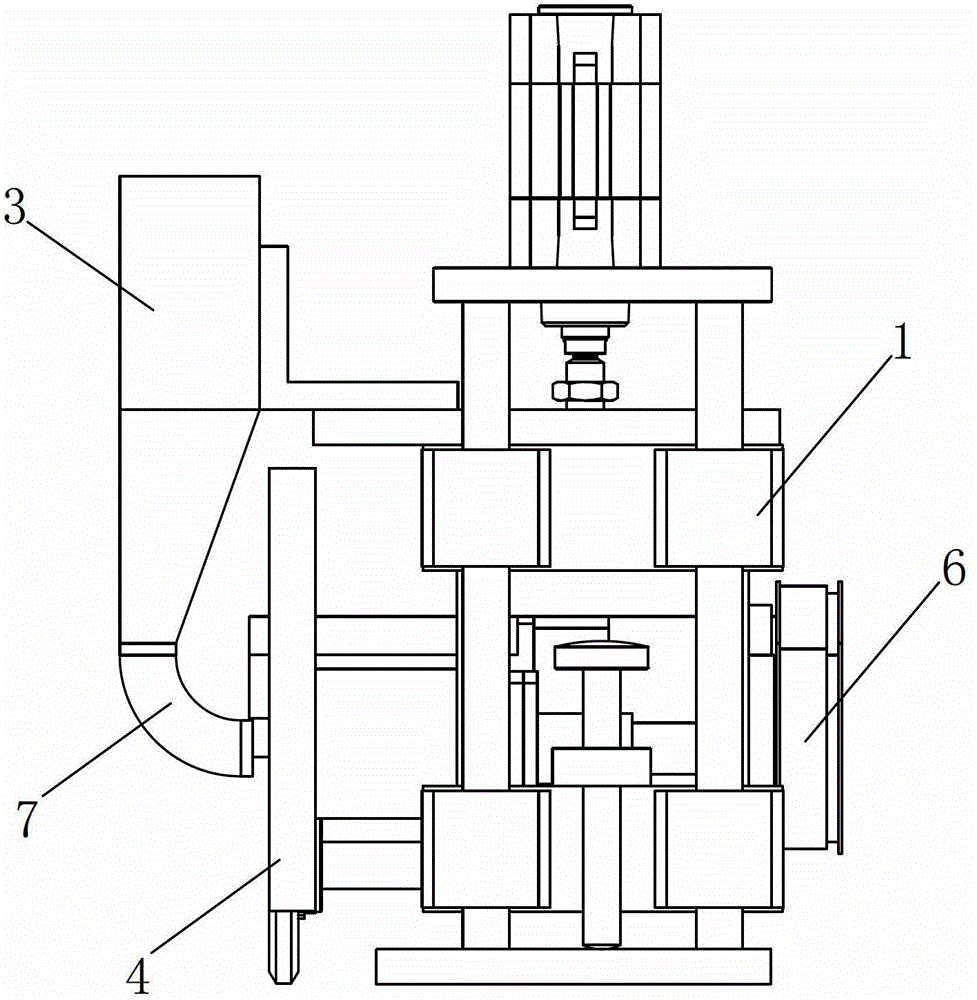

[0036] Such as figure 1The shown equipment for producing capsule filter rods includes a frame 1, a motor 2, a hopper 3, a feeding mechanism 4 and an insertion mechanism 5, and the motor 2 and the hopper 3 are installed on the frame respectively 1, the feeding mechanism 4 includes a feeding tray 4a and a gas distribution panel 4b respectively installed on the frame 1, the output end of the motor 2 is connected to the feeding tray 4a through a central shaft 6, and the The middle part of the feeding tray 4a is provided with a feed opening 4a1, and the side wall of the feeding tray 4a is provided with a discharge opening 4a2 along the circumferential direction, and the feeding tray 4a is provided with a discharge channel 4a3. The feed port 4a1 is communicated, the other end of the discharge channel 4a3 is communicated with the discharge port 4a2, and the feed bin 3 is communicated with the feed port 4a1 through the feeding pipeline 7; the insertion mechanism 5 Including a push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com