Crane working condition inquiring system and method

A query system and crane technology, applied in the field of crane working condition query system, can solve problems such as poor reliability and low work efficiency, achieve the effect of improving work efficiency and hoisting safety, and reducing the time for manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

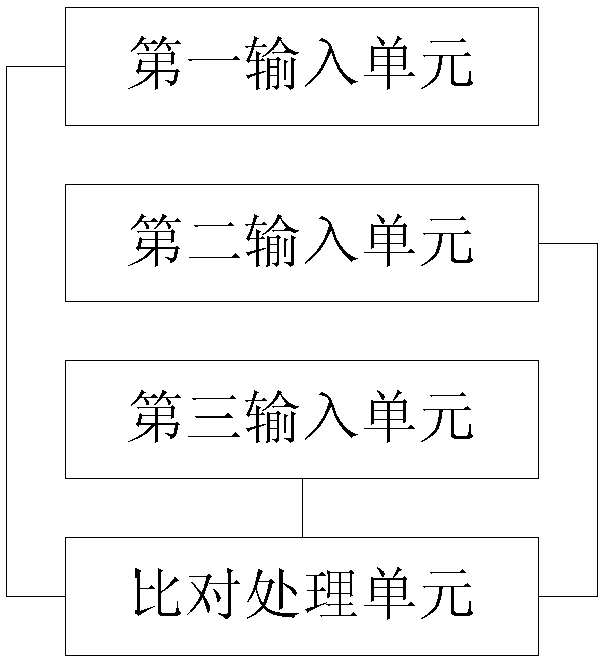

[0025] Please refer to figure 1 , the crane operating condition query system in this embodiment includes a first input unit, a second input unit, a third input unit and a comparison processing unit.

[0026] Wherein, the first input unit is used for the user to input the target weight (the weight of the hoisting object); the second input unit is used for the user to input the target range (the distance between the hoisting object and the center of gravity of the crane); the third input unit is used for the The user inputs the target height (the hoisting height of the hoisting object); the comparison processing unit is connected to the signal of the first input unit, the second input unit and the third input unit, and is used to compare the target weight, target amplitude, and target height with the crane performance table The hoisting weight, hoisting range, and hoisting height are compared, and the working conditions in which the hoisting weight is greater than or equal to th...

Embodiment 2

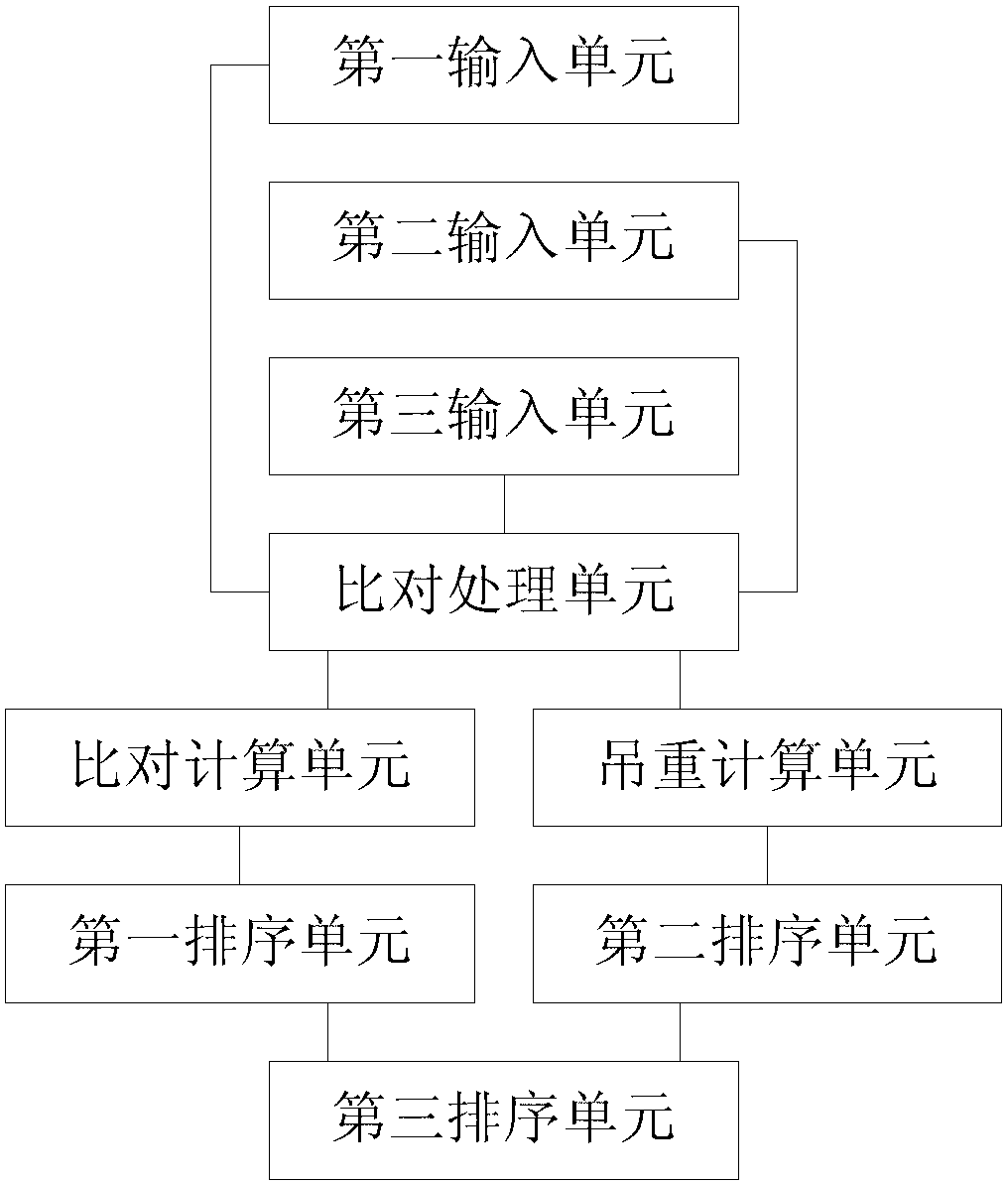

[0031] like figure 2 As shown, the second embodiment includes the first input unit, the second input unit, the third input unit and the comparison processing unit described in the first embodiment, the difference is that it also includes a comparison calculation unit, a first sorting unit , the hoisting calculation unit, the second sorting unit and the third sorting unit.

[0032] Wherein, the comparison calculation unit is connected to the comparison processing unit for comparing the listed working conditions with the current working conditions of the crane, and calculating the movement stroke required to switch from the current working condition to the listed working conditions ; The first sorting unit is connected with the signal comparison calculation unit for sorting the listed working conditions according to the size of the motion stroke from small to large; the hoisting weight calculation unit is connected with the comparison processing unit signal and used for calcula...

Embodiment 3

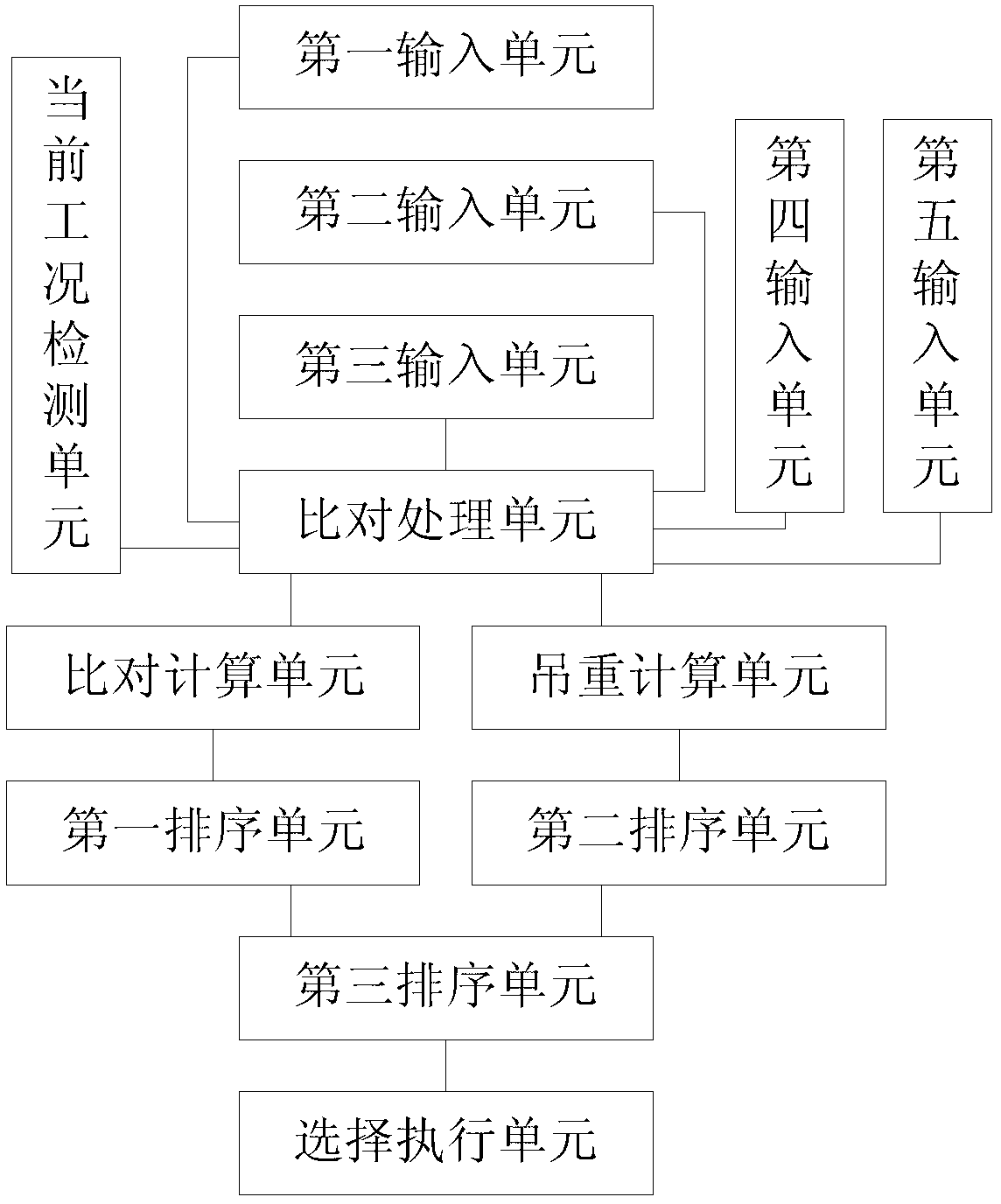

[0036] like image 3 As shown, the third embodiment includes the first input unit described in the second embodiment, the second input unit, the third input unit, the comparison processing unit, the comparison calculation unit, the first sorting unit, the hoisting weight calculation unit, the second The sorting unit and the third sorting unit also include a fourth input unit, a fifth input unit, a current working condition detection unit and a selection execution unit.

[0037] Wherein, the current working condition detection unit is signal-connected with the comparison processing unit, and is used to detect the status of the outrigger, the counterweight, the main arm and / or the auxiliary arm. The fourth input unit is signal-connected to the comparison processing unit for inputting counterweight state adjustment information, and the fifth input unit is signal-connected to the comparison processing unit for inputting outrigger state adjustment information; the comparison proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com