Rubber composition with low rolling resistance

A technology of rubber composition and low rolling resistance, which can be used in the optimization of rolling resistance, tire parts, transportation and packaging, etc. It can solve the problems of high energy consumption and high price of cross-linking monomers, and achieve reduced extrusion expansion and wear resistance No change in performance and improved wet skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The formula composition of the rubber composition is listed in Table 1, and the preparation of the rubber compound is the same as that of the comparative example.

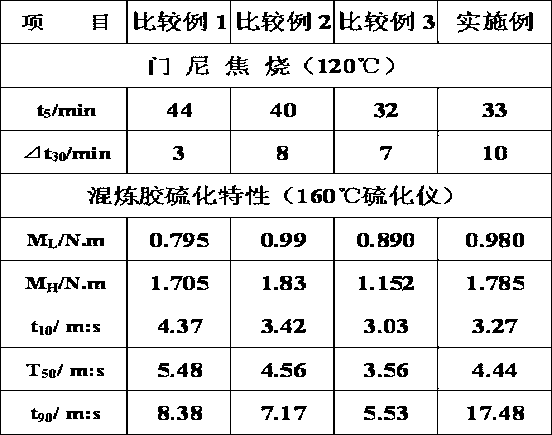

[0046] The main properties of the rubber compositions of Comparative Examples and Examples are listed in Tables 2-4.

[0047] As can be seen from the results of Table 3 and Table 4, the embodiment has reached a good balance in terms of rolling resistance, wet skid resistance and wear resistance. Compared with Comparative Example 1, the rolling resistance has reduced by 15.3%, and the wet skid resistance Slightly improved, wear resistance is largely unaffected. At the same time, the compression fatigue temperature rise of the rubber composition of the example is also small. The rolling resistance of Comparative Example 2 was only reduced by 5%, and the rolling resistance of Comparative Example 3 was greatly reduced, but the wear resistance was seriously affected.

[0048] The rubber composition of the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com