Bionic anti-sticking lyophobic and oleophobic pasting film

A hydrophobic and oleophobic, film-sticking technology, applied in the direction of adhesives, film/flake adhesives, etc., can solve the problems of hidden safety hazards, strong penetration, large feature size, etc., to reduce the trouble of cleaning and avoid contamination with oil. , Improve the effect of easy dirty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

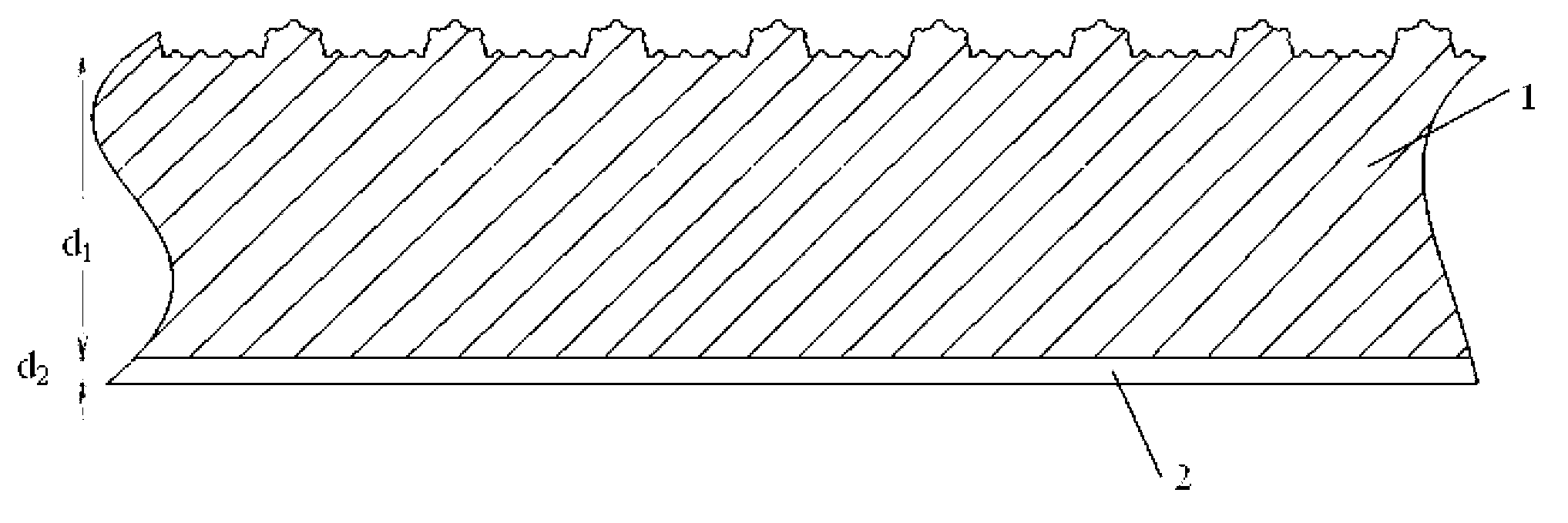

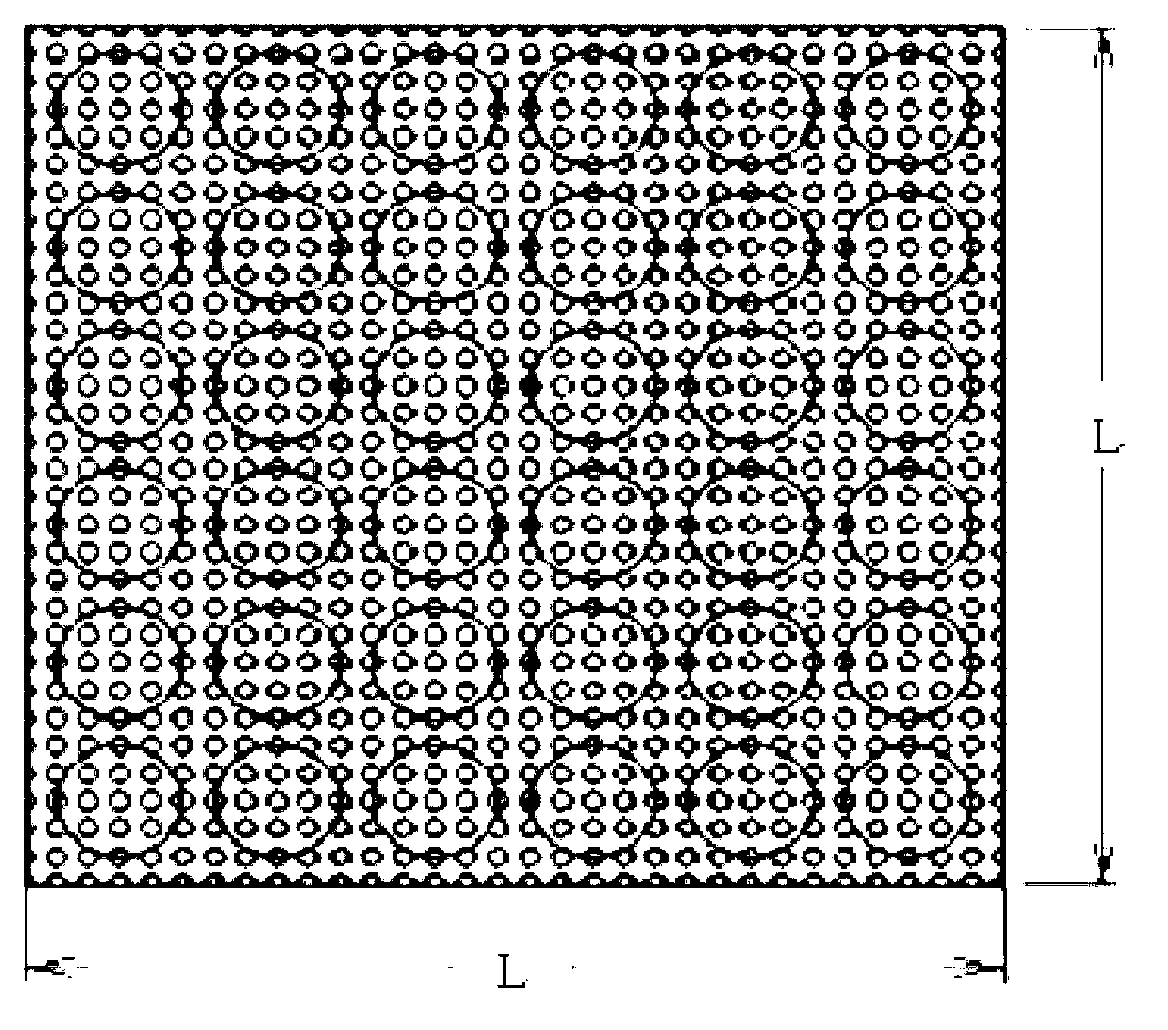

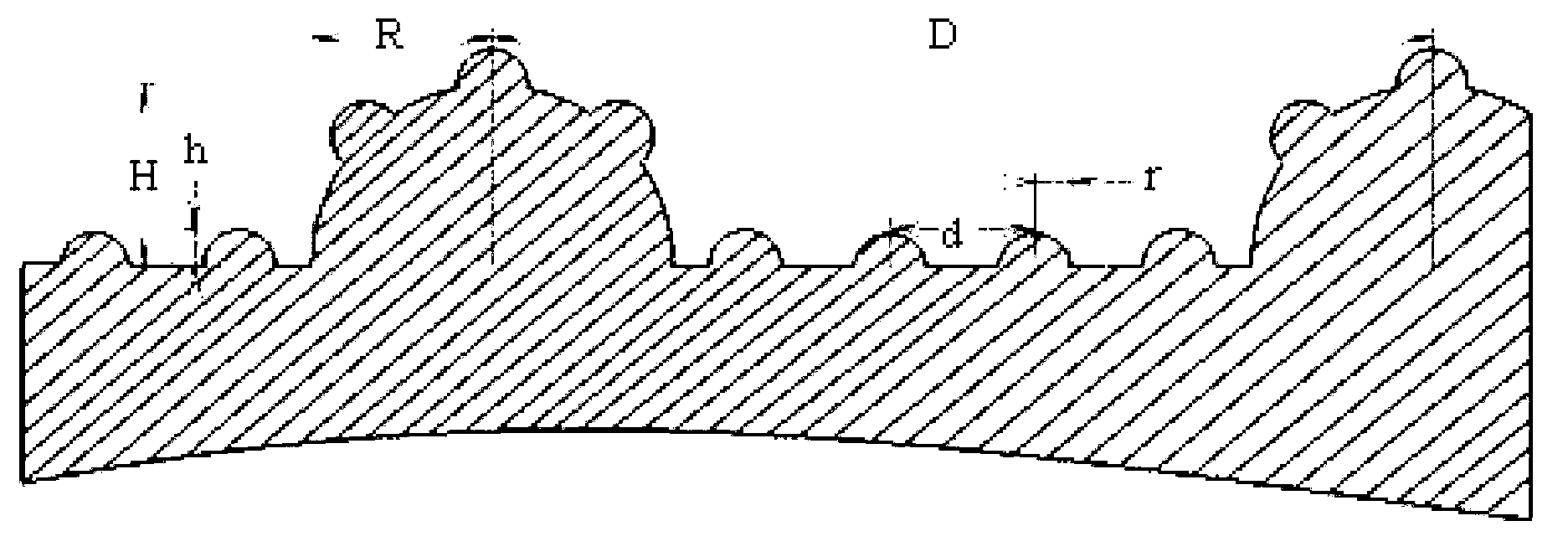

[0024] Embodiment 2 Automobile non-stick mud sticking film

[0025] According to the requirements of the present invention, a bionic hydrophobic and oleophobic car non-stick film with anti-stick function is designed. First of all, it is necessary to process the hot-pressing mold, which is made of gray cast iron, and use a picosecond laser to process the micro-morphology of hexagonal prism pits on its surface. The radius of the circumscribed circle of the regular hexagon at the bottom of the first-level pit is 80um, the depth of the pit is 50um, and the distribution density of the pit is 50%. According to the calculation of the area occupancy ratio of the convex hull structure, the distance between the structural units of the first-level pit is calculated. The center distance is 200um, and the number of pit units is 25 on the processing surface with a format of 1mmx1mm. The radius of the circumscribed circle of the regular hexagon at the bottom of the second-level pit is 5um, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com