After-forging hydrogen diffusion and annealing method of forging material

A forging and post-forging technology, which is applied in the field of post-forging hydrogen expansion annealing of forging materials, can solve the problems of poor adaptability of large-scale steel ingot forging materials and continuous casting billet forging materials, fixed time adjustment coefficient, and inability to eliminate white spots, etc., to achieve Improve the utilization efficiency of the furnace table, strong adaptability, and the effect of eliminating white spot defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

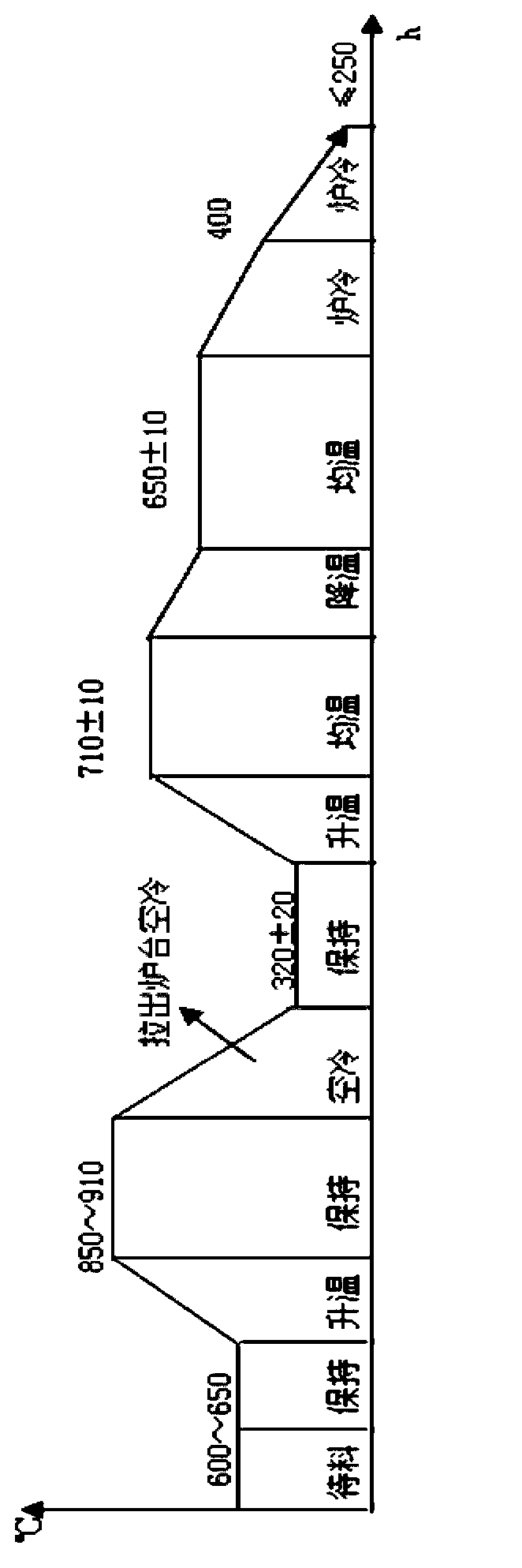

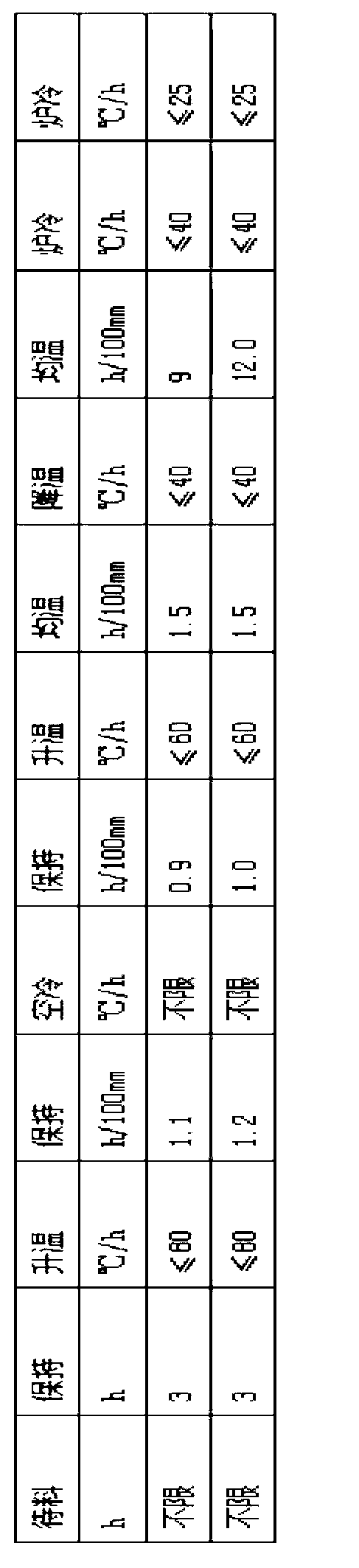

[0077] The equivalent diameter of the forging is 250mm, and the specific hydrogen expansion annealing treatment method is as follows:

[0078] Step A, pull out the forging material at 600-610°C and cool it to 300-310°C and stay for 3 hours;

[0079] Step B, heating the forging material after air-cooling in step A to 660-670°C, with an average temperature of 1.5h / 100mm and then holding the temperature for 7h / 100mm;

[0080] Step C, cooling the forging material after the uniform temperature and heat preservation in step B to 400 °C at a cooling rate of 30 °C / h, and then cooling to 200 °C at a cooling rate of 20 °C / h, and then the forging material is released from the furnace.

Embodiment 2

[0082] The thickness of the forging is 500mm, and the specific hydrogen expansion annealing treatment method is as follows:

[0083] Step A, pull out the forging material at 620-630°C and cool it to 320-330°C and stay for 7 hours;

[0084] Step B, heating the forging material after air cooling in step A to 660-670°C, keeping the average temperature for 1.5h / 100mm and then keeping it for 9h / 100mm;

[0085] Step C, cooling the forging material after the uniform temperature and heat preservation in step B to 400 °C at a cooling rate of 25 °C / h, and then cooling to 150 °C at a cooling rate of 15 °C / h, and then the forging material is released from the furnace.

Embodiment 3

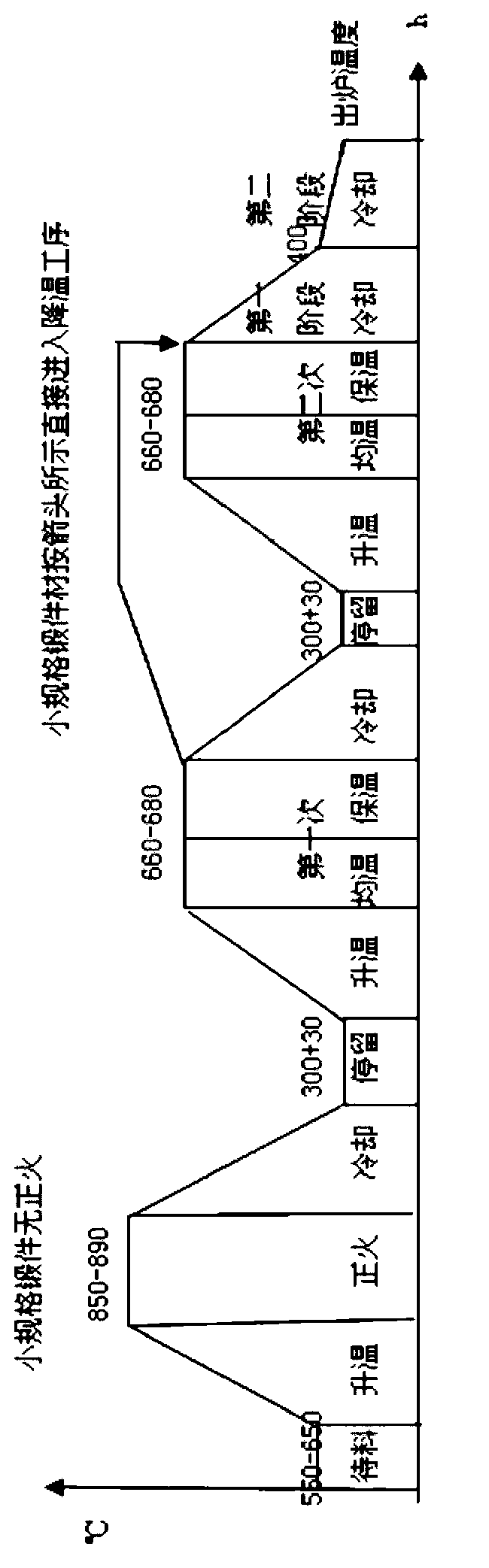

[0087] The thickness of the forging is 900mm, and the specific hydrogen expansion annealing treatment method is as follows:

[0088] Step 1: Warm up the forging material at 630-650°C to 880-890°C for normalizing, and hold it for a total of 8 hours after uniform temperature;

[0089] Step 2: Hang the forgings after normalizing in Step 1 from the trolley and air cool to 300-310°C and stay for 8 hours;

[0090] Step 3, heat up the forging material after step 2 air-cooling to 670-675°C, keep the temperature for 1.5h / 100mm and then keep it for 9h / 100mm;

[0091] Step 4: Air cool the forged material after step 3 uniform temperature and heat preservation to 400°C, then furnace cool to 300-330°C and stay for 7 hours; 6h / 100mm;

[0092] Step 5: Cool the forging material after step 4 uniform temperature and heat preservation to 400 °C at a cooling rate of 25 °C / h, and then cool it to a temperature below 150 °C at a cooling rate of 10 °C / h, and then release the forging material from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com