Thread creation element for a spinning position of an air jet spinning machine and method for preparing a spin process on an air jet spinning machine

A technology of air-jet spinning machine and components, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, and can solve the problem that the error situation cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

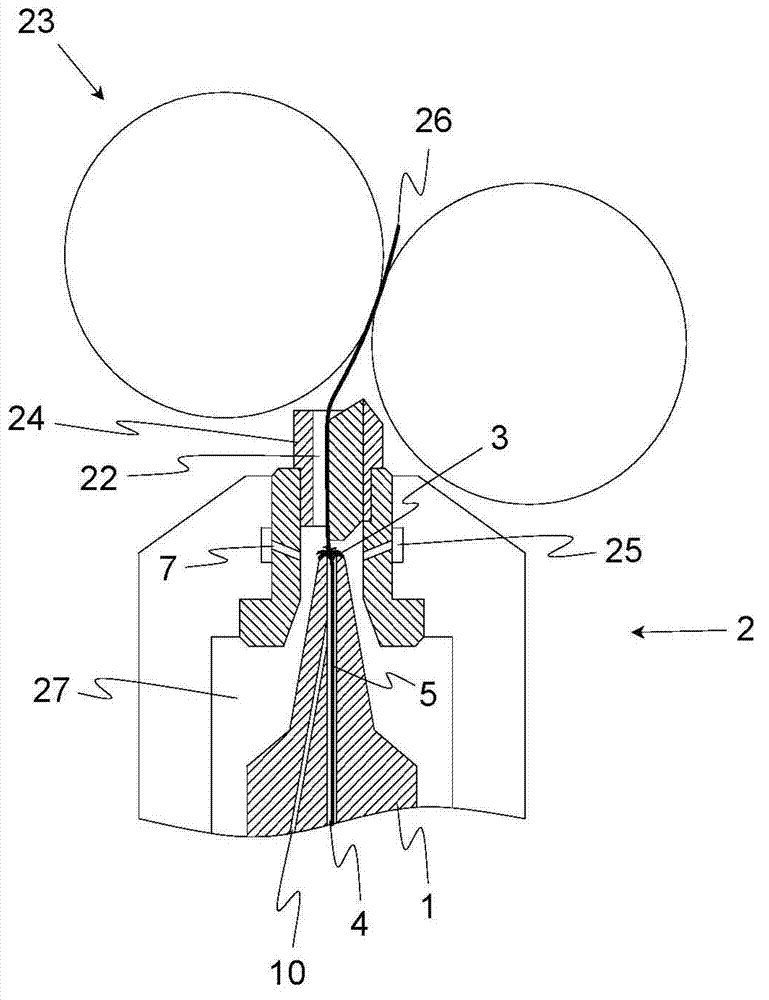

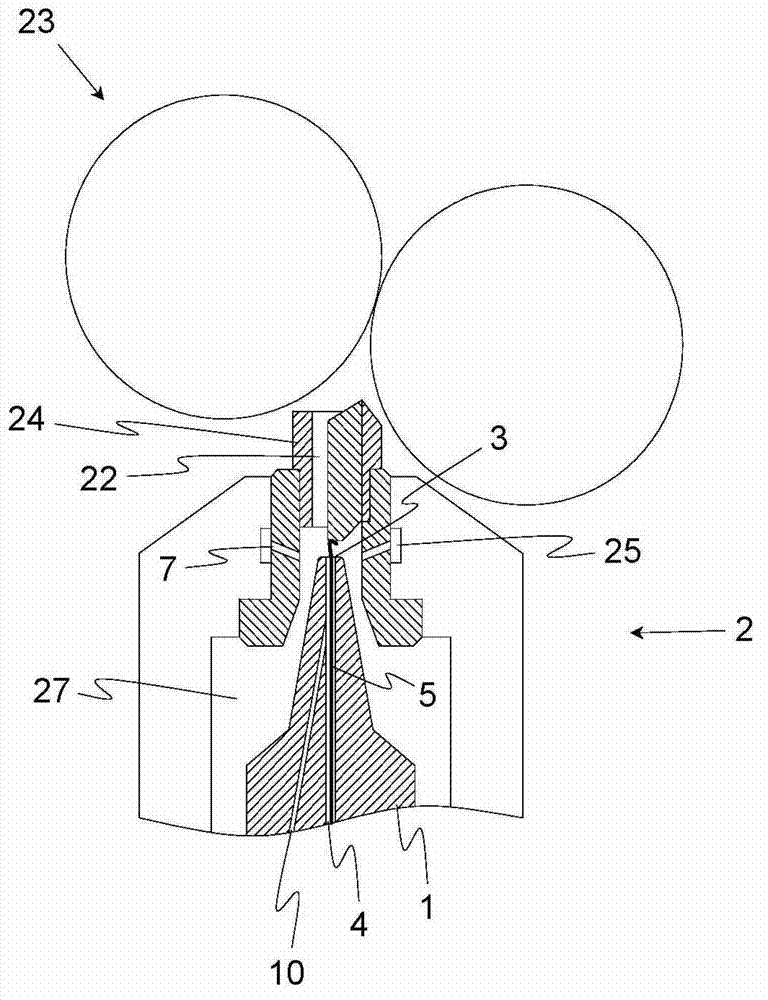

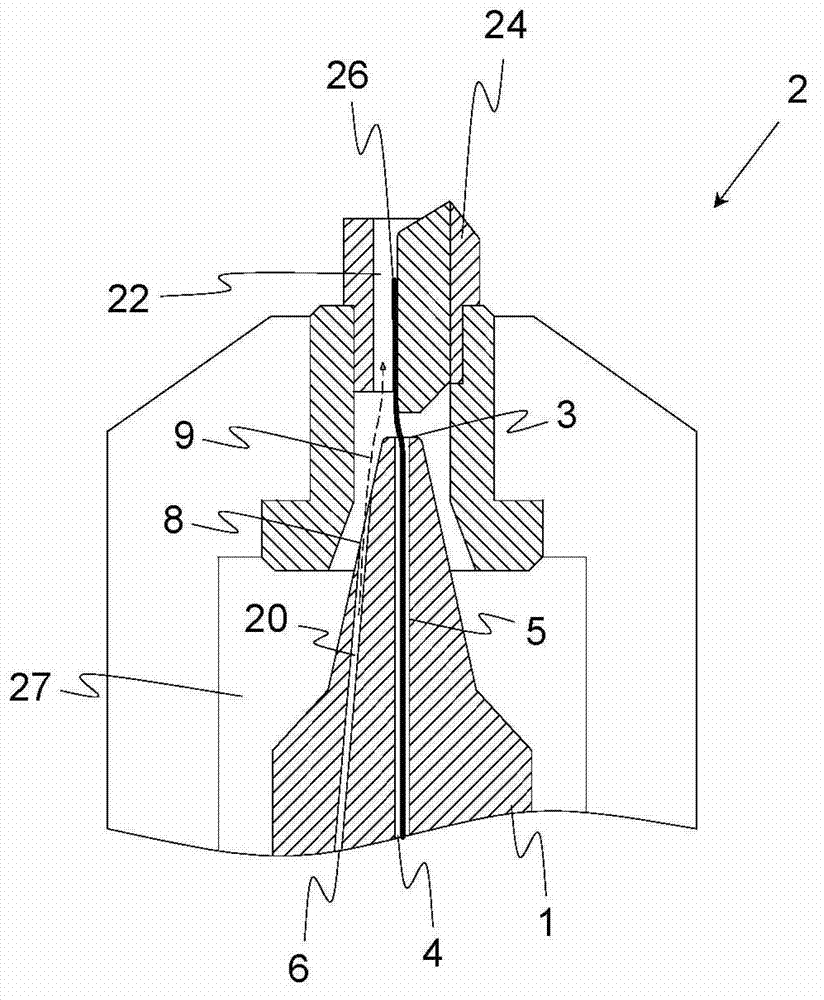

[0032] figure 1 The spinning position 2 of an air-jet spinning machine according to the prior art is shown in a partially cutaway side view. The spinning position 2 contains a fiber guide element 24 through which the fiber material 26 to be spun and which is mostly present as a drawn fiber strip reaches the so-called swirl chamber 27 of the spinning position 2, in which Finally, the original spinning process is carried out. The drafting usually takes over a drafting unit arranged upstream of the fiber guide element 24 , from which the drafted fiber strip is drawn by means of a pair of withdrawal rollers. Finally, the fiber strip is preferably gripped by the pair of rollers serving as the pair of supply rollers 23 which should be arranged as directly as possible in connection with the fiber guide element 24 in order to avoid false delays.

[0033] After the fiber material 26 has passed the fiber guide element 24 via the guide channel 22 , it reaches the area of a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com