Construction method for restoring surface structure and cracks on asphalt pavement

A technology of asphalt pavement and surface structure, which is applied in the field of road rolling, which can solve the problems of obstructing traffic, slow construction period, and stone consumption, and achieve the effects of less interference, improved anti-skid performance, and increased surface structure depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Five years after the asphalt pavement of an expressway was opened to traffic, the pavement surface was smooth. The structural depth and lateral force coefficient of the pavement surface were measured according to the method stipulated in the "On-site Test Regulations for Highway Subgrade Pavement" (JTG E60-2008). The results are shown in Table 1. Also, the pavement has more surface cracks. Select a 2km long road section, apply the hot-spur rolling equipment and construction technology of the present invention to repair the surface structure of the asphalt pavement, and fill up the surface cracks at the same time.

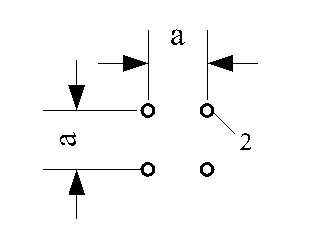

[0024] First, traffic in the pending lane is closed. Use an emulsified asphalt sprinkler to evenly spread 0.2kg / m on the dry and clean asphalt road surface 2 emulsified asphalt. After the emulsified asphalt is demulsified, hot-spur rolling begins.

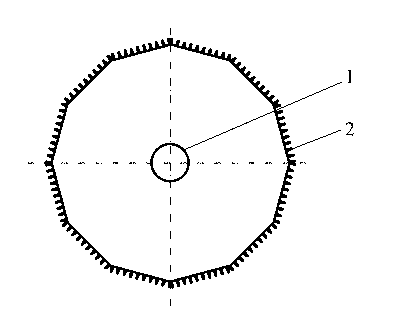

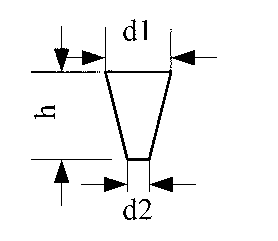

[0025] Heat the rolling wheel 30 minutes in advance so that the temperature of its surface is 120°C, and sta...

Embodiment 2

[0032] On the same expressway as in Example 1, select a 2km long road section adjacent to Example 1, and apply the hot-spur rolling equipment and construction technology of the present invention to repair the surface structure of the asphalt pavement and fill up the surface cracks simultaneously.

[0033] First, traffic in the pending lane is closed. Use an emulsified asphalt sprinkler to evenly spread 1.0kg / m on the dry and clean asphalt road surface 2 emulsified asphalt. After the emulsified asphalt is demulsified, hot-spur rolling begins.

[0034] Heat the rolling wheel 50 minutes in advance so that the surface temperature is 180°C, and start rolling. The rolling speed is 6km / h. 10 minutes after the end of the rolling, the road surface temperature drops below 60°C, and the vehicle traffic will resume.

[0035] A heating device is arranged inside the rolling wheel adopted. The heating device is a ZYR-50 gas-fired air heater produced by Shanghai Maolu Electric Co., Ltd.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com