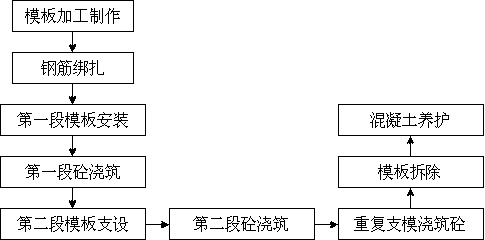

Construction process for coating faced concrete outside ultrahigh steel tube column after floor is closed

A technology of fair-faced concrete and construction technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., which can solve difficulties in ensuring concrete quality, inability to use large-scale machinery, concrete flow and internal vibration difficulties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

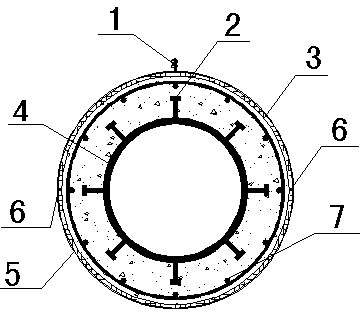

[0013] Step 1. Template processing and production

[0014] 1 template design

[0015] Fair-faced concrete has higher requirements on formwork strength, stiffness and panel finish. Select 18mm thick shaped cylindrical wood plywood with 0.8mm thick endurance board system inside, which can ensure the surface quality and appearance of fair-faced concrete and control project costs.

[0016] 2 Template processing and production

[0017] 1) Fully clean the inner surface of the formwork, clean the surface dust, oil, etc., and ensure that the endurance board and the inner surface of the formwork are firmly pasted.

[0018] 2) Set up an operation platform, cut the endurance board on the platform according to the perimeter and height of the template, and use a wallpaper knife for cutting, so that the cutting size is correct, without flying thorns and burrs.

[0019] 3) 801 glue is used for pasting the endurance board. The glue should be applied evenly to avoid accumulation and flow....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com