Producing well shaft combined gravity assisted heat pipe

A gravity heat pipe and combined technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as long inner cavity, temperature increase, heat transfer failure, etc., to improve economic benefits and increase success rate , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

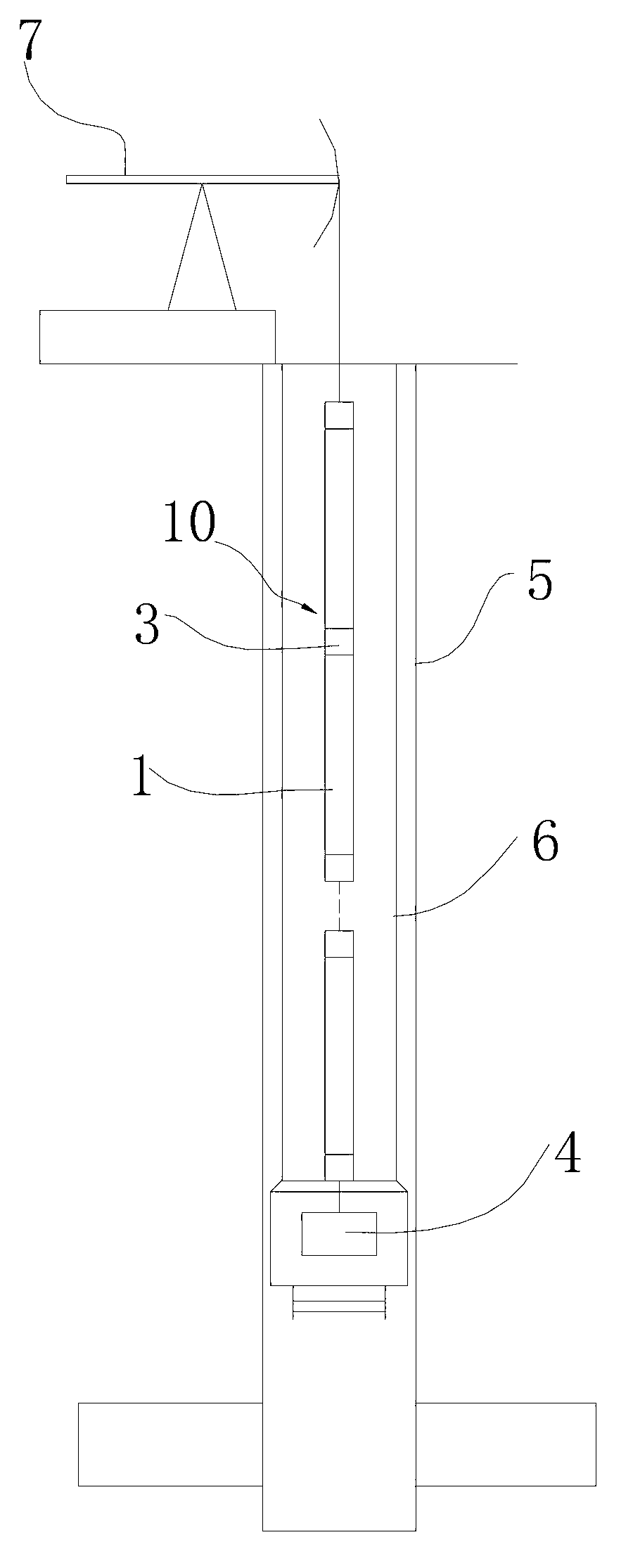

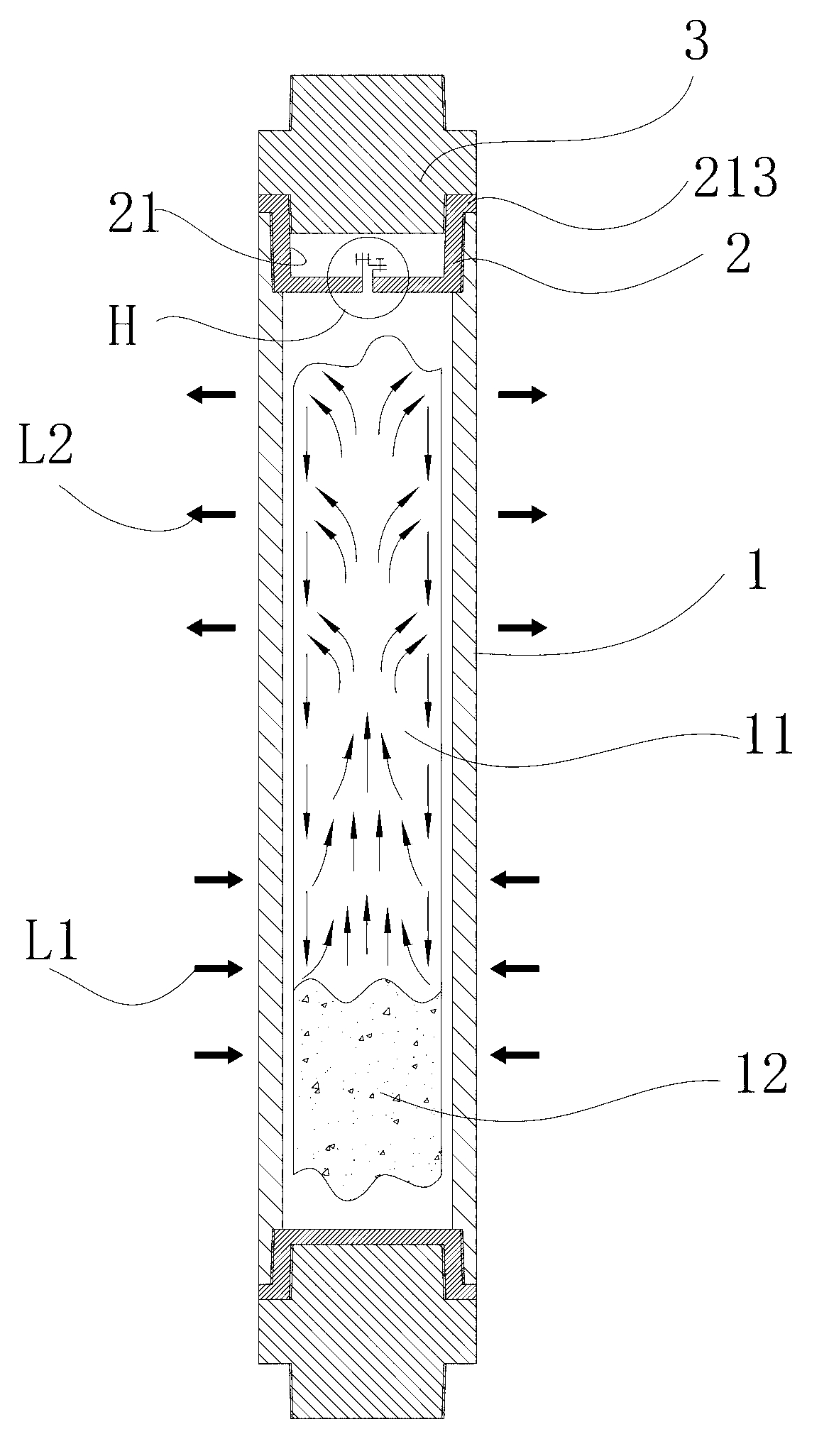

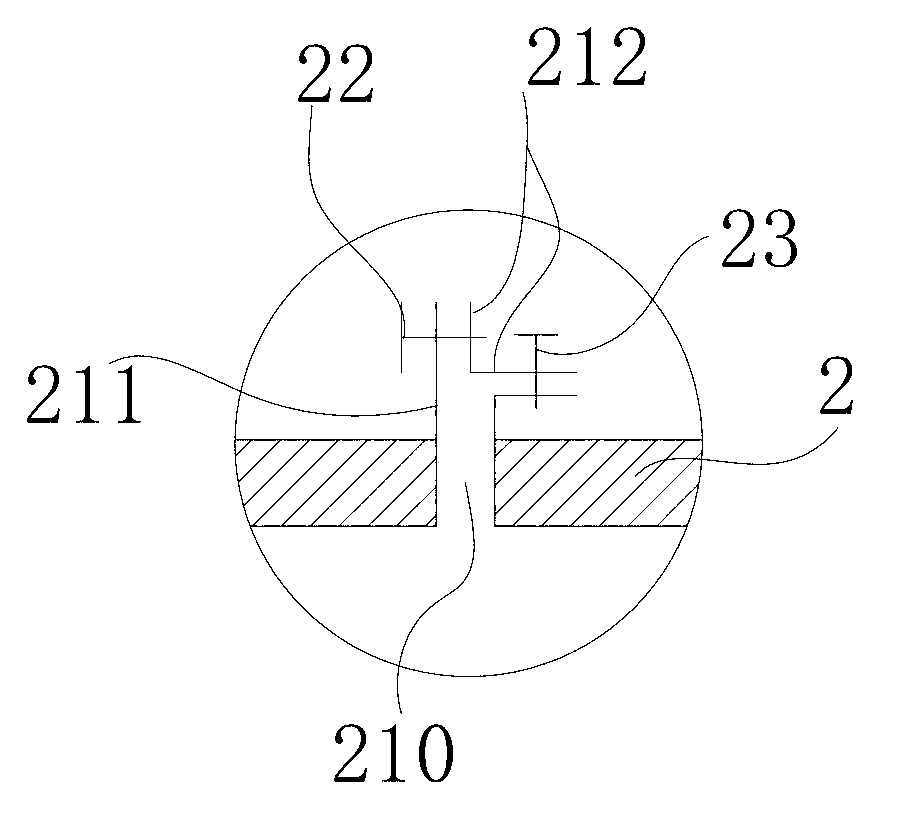

[0021] The present invention provides a combined gravity heat pipe of an oil production well shaft, which includes at least two gravity heat pipe units. The inner cavity of the gravity heat pipe unit is a closed cavity, and the closed cavity is filled with a working fluid that can be formed into a gaseous state when heated, and the sealing plug is concavely provided with a connecting groove toward the center of the gravity heat pipe unit ; Wherein, each of the gravity heat pipe units is connected sequentially through a connecting head to form the combined gravity heat pipe of the oil wellbore, and the upper and lower ends of the connecting head are correspondingly embedded in two adjacent In the connecting grooves of the two sealing plugs facing each other between the gravity heat pipe units, and screwed and fixed with the side walls of the connecting grooves, when the combined gravity heat pipe of the oil wellbore is placed in the wellbore, due to various The gravity heat pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com