Multi-impeller wind power generation windmill

A windmill and wheeled technology, applied in the field of multi-wheel wind power generation windmills, can solve the problems affecting the popularization and application of wind power generation, high power generation cost, and high blade manufacturing cost, and achieve cost reduction, power generation efficiency improvement, and windmill efficiency improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

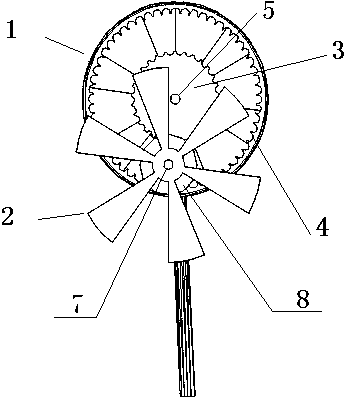

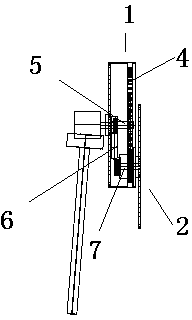

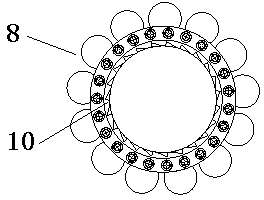

[0011] like figure 1 , 2 , 3, it consists of a main wheel 1 and N auxiliary wheels 2, and N auxiliary wheels 2 are at least one. The angle between the axis of the windmill should generally be greater than 90 degrees and less than 120 degrees, which is conducive to the approach of the center of gravity of the windmill to the tower. The main wheel 1 is fixed on the main wheel shaft 5 through bearings; The teeth on 4 point to the center of the main shaft 1, and a central toothed plate 3 is fixed on the main wheel 1, and the secondary wheel 2 is meshed with the main wheel 1 through the gear 8 on it. The specific connection method is: the gear 8 of the secondary wheel 2 One side of the main wheel 1 is meshed with the ring gear 4 on the main wheel 1, so that the wind force obtained by the secondary wheel 2 acts on the outer edge of the main wheel 1 to increase the power of the main wheel 1, and the other gear 8 of the secondary wheel 2 The symmetrical side is meshed with the centr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap