Pneumatic high pressure regulating valve

A pneumatic high-pressure, regulating valve technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of small output force, low operating pressure difference, leakage and other problems of pneumatic actuators, and achieve the effect of reducing the flushing speed and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

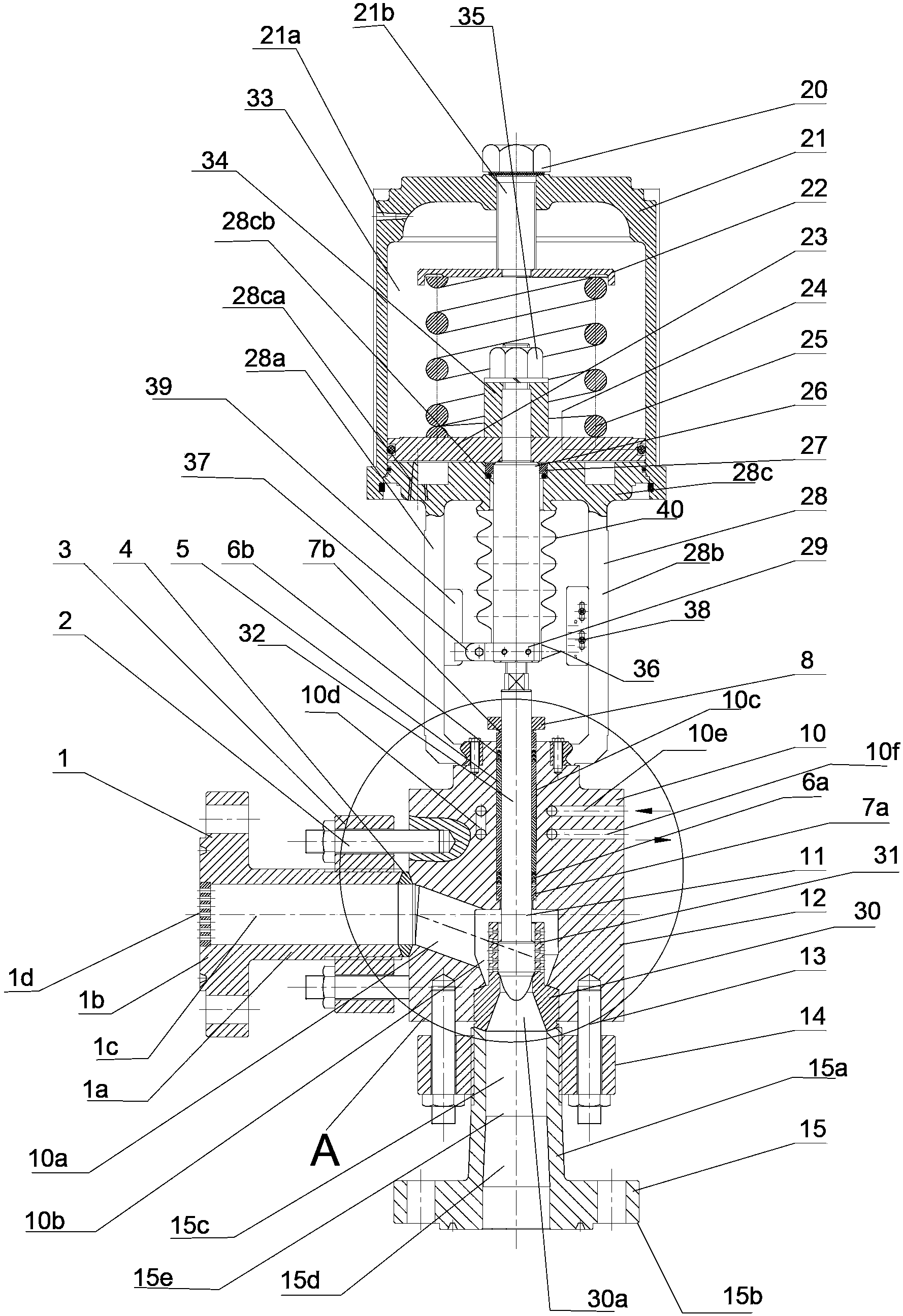

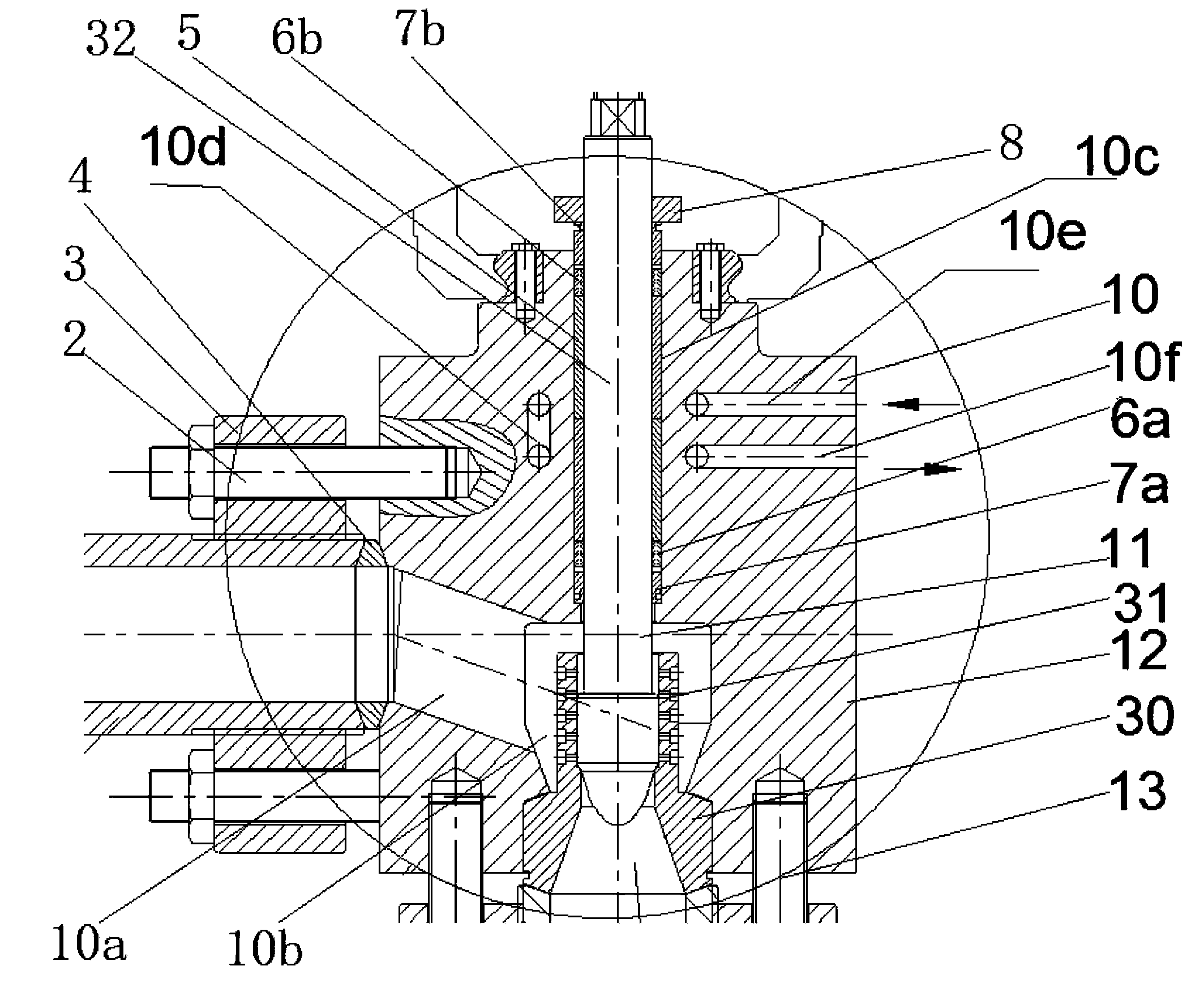

[0065] see figure 1 and figure 2 , an air-opening pneumatic high-pressure regulating valve given in the figure includes an air-opening spring-cylinder actuator and a valve part arranged below the air-opening spring-cylinder actuator.

[0066] The valve part includes a valve body 10, and the valve cover on the valve body 10 and the valve body are integrally forged by stainless steel, so as to avoid leakage points generated by the flange connection. The valve body 10 is provided with an inlet flow channel 10a, an outlet flow channel 10b and a stem hole 10c which communicate with each other. The inlet flow channel 10a and the outlet flow channel 10b are streamlined, and the flow channels are smooth without dead zones. The outlet channel 10b is coaxially arranged with the valve stem hole 10c, and the angle between the central axis of the inlet channel 10a and the center axis of the outlet channel 10b is 120°, which can make the medium flow smoothly and at the same time generate ...

Embodiment 2

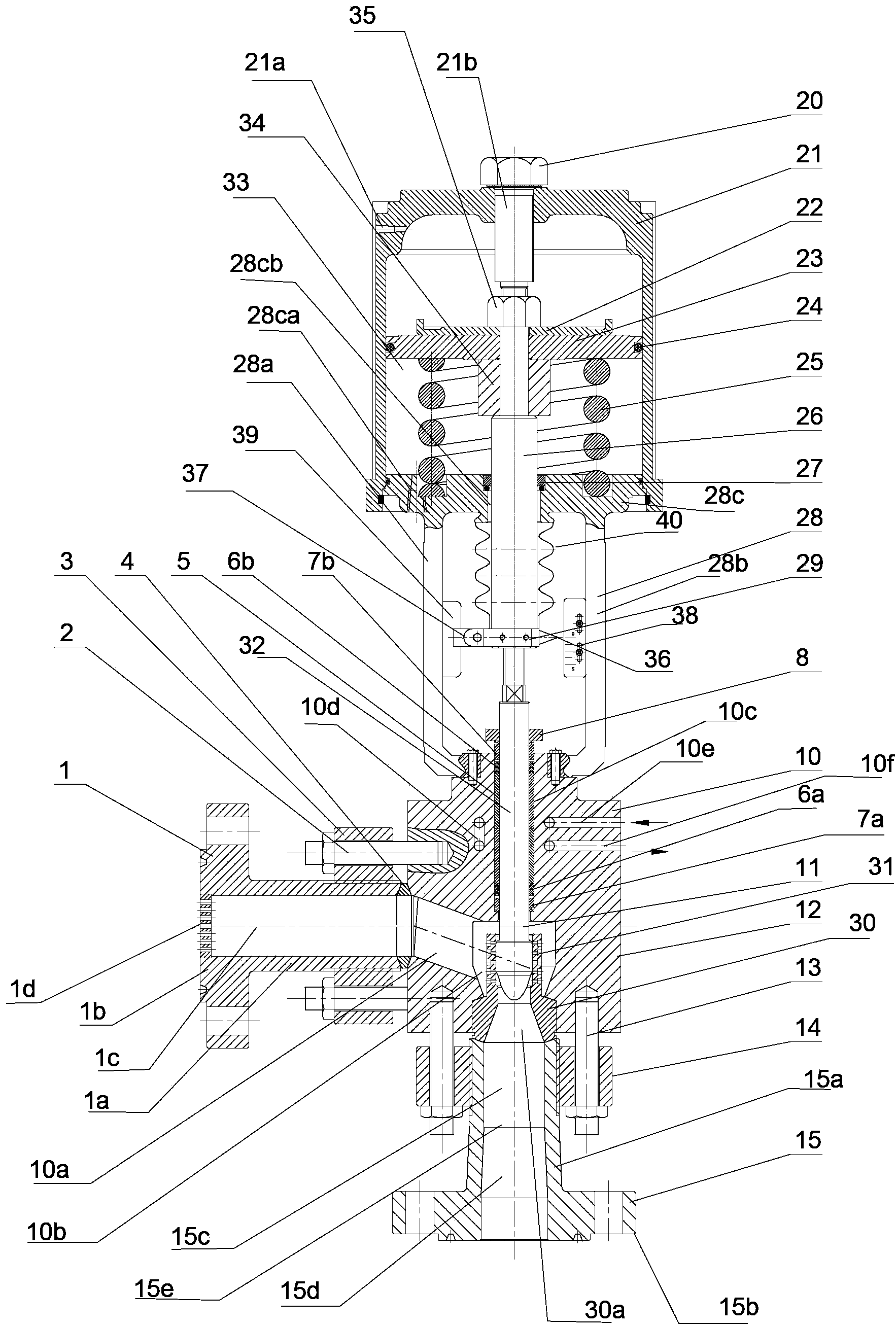

[0084] see image 3 , the pneumatic high-pressure regulating valve of this embodiment shown in the figure is an air-closing pneumatic high-pressure regulating valve, including an air-closing spring-cylinder actuator and a valve part arranged below the air-opening spring-cylinder actuator . Wherein the valve part is the same as that of Embodiment 1.

[0085] The air-to-close spring cylinder actuator has a different structure from the air-to-open spring cylinder actuator in Embodiment 1. The air-to-close spring cylinder actuator includes a bracket 28, and the bracket 28 has two arms 28a, 28b. , the lower ends of the two support arms 28a, 28b are fixed on the valve body 10 by bolts, and a cylinder base flange 28c is integrally connected to the upper ends of the two support arms 28a, 28b, and a gas inlet flange 28c is provided on the cylinder base flange 28c. hole 28ca and a central push rod hole 28cb.

[0086] The cylinder body 21 in the air-open spring cylinder actuator is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com