An equal-flow air distributor for supplying air to high-pressure disc gas bearings

An air flow distributor and gas bearing technology, which is applied in the direction of pipe components, branch pipelines, mechanical equipment, etc., can solve the problem that the high-pressure disc gas bearing gas supply system cannot provide, can not achieve split flow and export it in an equal amount, and the final gas problems such as low pressure, to achieve the effect of satisfying structural strength design, novel structure and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

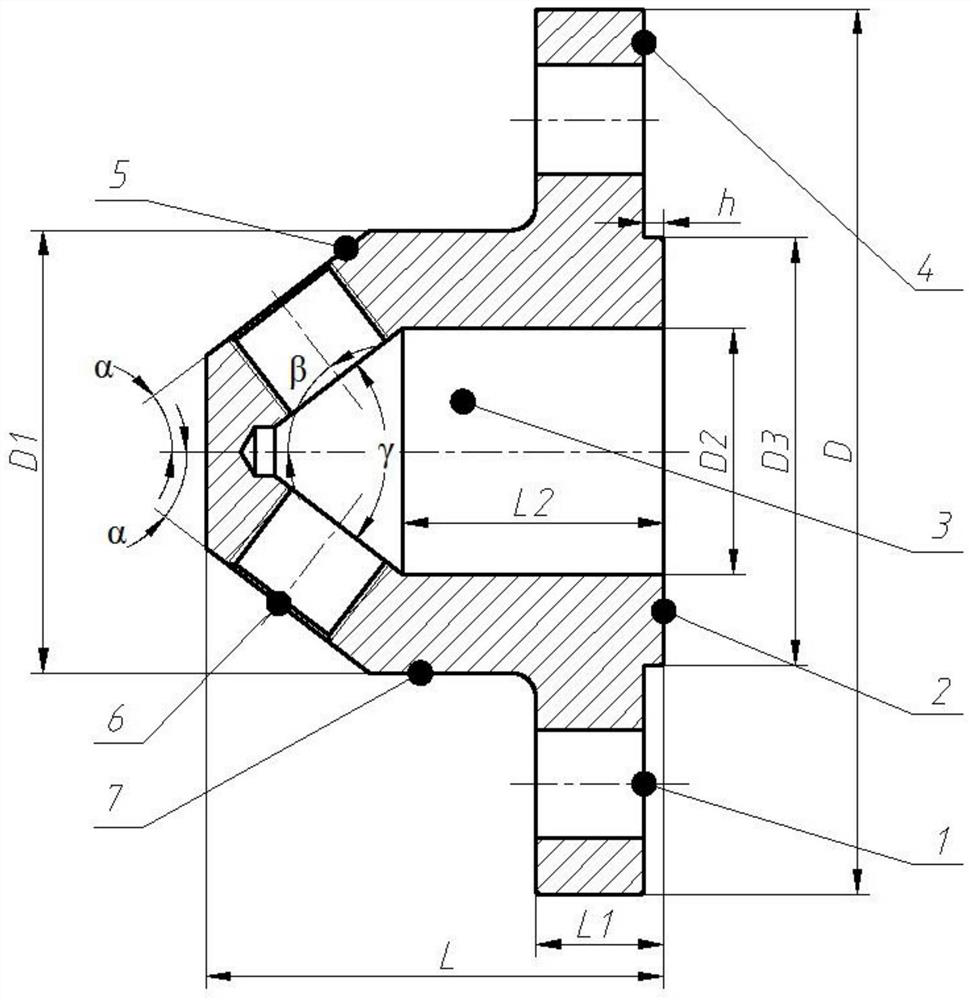

[0043] Such as Figure 1-Figure 3 As shown, there is a gas flow distributor with two branch pipes, which is used to split the flow to two working discs of a set of high-pressure disc gas bearings, which includes a centrally symmetrical cylindrical air flow cavity 7, and the cylindrical air flow The inside of the chamber 7 is provided with a centrally symmetrical cylindrical-cone transitional gas chamber 3, and the right end of the cylindrical airflow chamber 7 is provided with a connecting disc 4; the central axis of the cylindrical airflow chamber 7 is located at the same on a straight line;

[0044]The left end of the cylindrical air flow chamber 7 is milled with two slopes 5 at an angle of 37.5° with the central axis, and the slopes 5 are evenly distributed along the central axis; each slope 5 has a threaded hole 6 in the center, and the threaded hole 6 is connecte...

Embodiment 2

[0060] see Figure 9-Figure 11 , shows a gas flow distributor with four branch pipes for splitting equal flows to the four working discs of two sets of high-pressure disc gas bearings.

[0061] Except for increasing the number of branch pipelines, all the other features are the same as those in Embodiment 1.

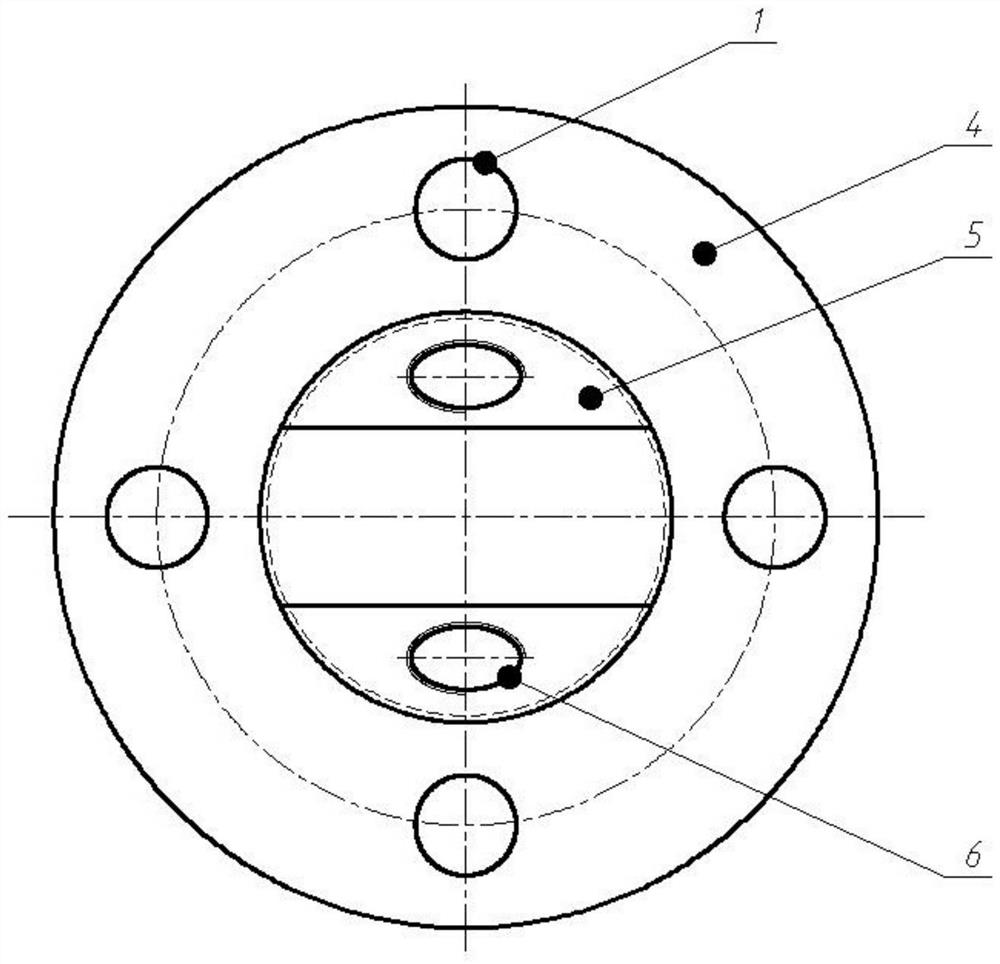

[0062] Figure 9 Shown is a left side view of the distributor with four branch pipes, and the figure shows four symmetrical slopes 5 up and down, left and right, and the position distribution of four symmetrically arranged threaded holes on the slopes.

[0063] Figure 10 Shown is the top view of the distributor with four branch pipes, which shows the top view shape and position distribution of the four inclined planes 5 milled on the cylindrical air flow chamber 7 and the four threaded holes 6 processed .

[0064] The distributor embodiment 2 is similar to the geometric parameters of embodiment 1. Figure 11 When the air supply pressure is 0.9MPa, the outlet pressu...

Embodiment 3

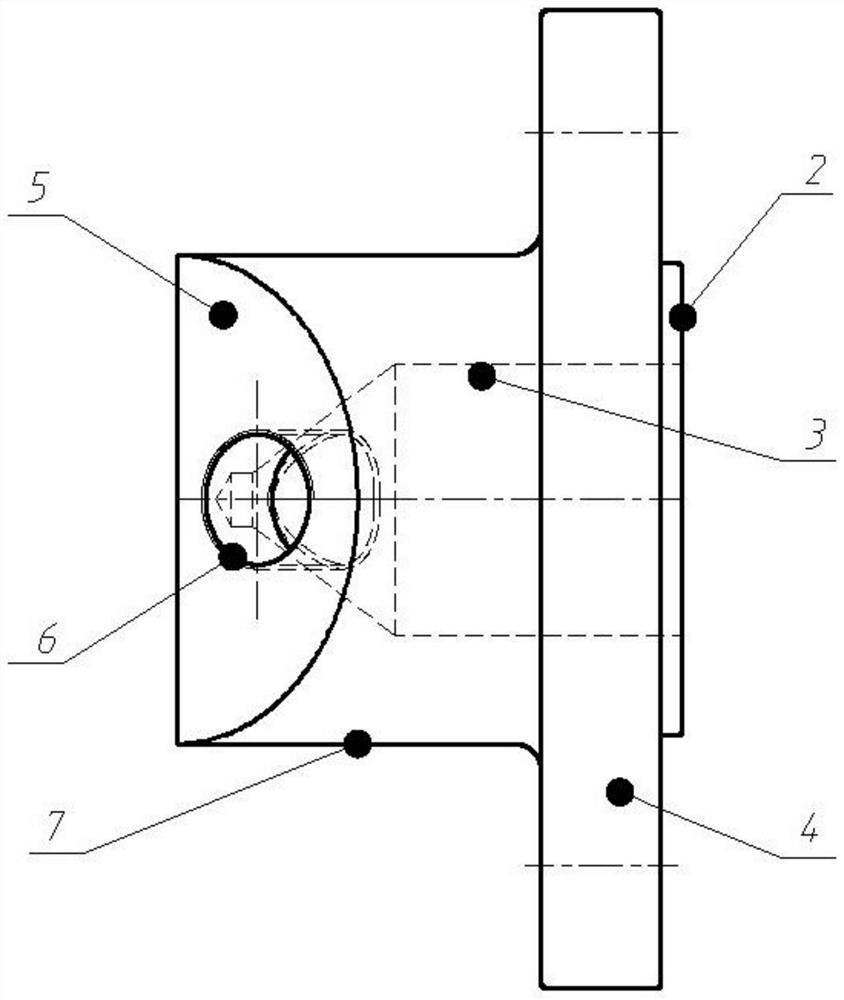

[0067] see Figure 14 , Figure 15 , Figure 16 , shows an airflow distributor when the number of branch pipes is equal to 4, but the outflow angle changes, and is used to divide the flow to the four working discs of the two sets of high-pressure disc gas bearings.

[0068] The left end of the cylindrical airflow cavity 7 is milled with four slopes 5 at an angle of 45° with the central axis, and the slopes 5 are evenly distributed along the central axis; each slope 5 is provided with a threaded hole 6, and the threaded hole 6 is connected to the central axis. The angle between the central axis is 30°;

[0069] The right end of the cylindrical-cone transitional gas cavity 3 is cylindrical, and the left end of the cylindrical-conical transitional gas cavity 3 has a conical angle of 40°, and the cylindrical-conical transitional gas cavity 3 communicates with the threaded hole 6 .

[0070] All the other features are the same as in Embodiment 1.

[0071] Figure 14 Shown is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com