Roller dryer with examination clearing port

A cleaning port and drum-type technology, which is applied in the field of dryers and drum dryers, can solve the problems of limited position of the operator when handling, general drying effect, inconvenient operation and maintenance, etc., to achieve the inspection and cleaning of the feed end of the drum Convenience, improved drying effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

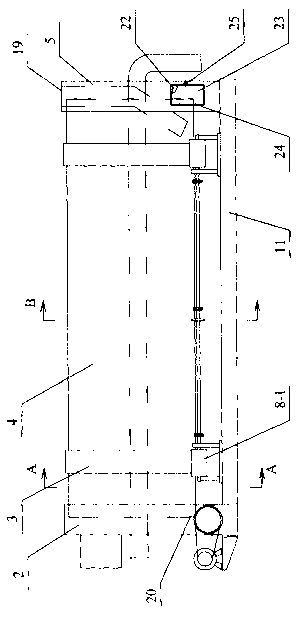

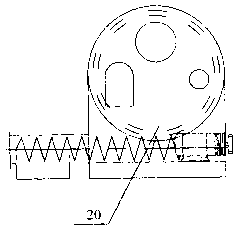

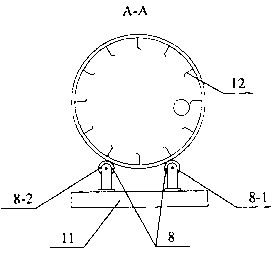

[0018] Such as Figure 1~4 As shown: a tumble dryer with an inspection and cleaning port, including a cylinder body 4 , a tail cover 2 , a head cover 5 , a frame 11 and a power mechanism 13 . Head cover 5 and tail cover 2 are positioned at the two ends of cylinder 4, cylinder body 4 is the cylinder 4 of inclination, and head cover 5 is positioned at the high end of tilt cylinder 4, and tail cover 2 is positioned at the low end of tilt cylinder 4. The power mechanism 13 is connected with the drum 4 through the roller 8, and the power mechanism 13 drives the drum 4 to rotate. The high end of the drum 4 is provided with a material inlet 19 and a hot air inlet, and the low end of the drum 4 is provided with a material outlet 20 and a hot air outlet. A material outlet 20 is provided at the end. Cylindrical body 4, tail end cover 2, head cover 5 are all installed on the frame 11. The material plate 12 is fixedly connected to the inner circumference of the drum 4 . Back-up ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com