Bean-type drying device

A drying device and bean technology, applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems that bean products cannot be directly stored or transported, secondary pollution, waste, etc., and achieve working results Good, high degree of automation, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

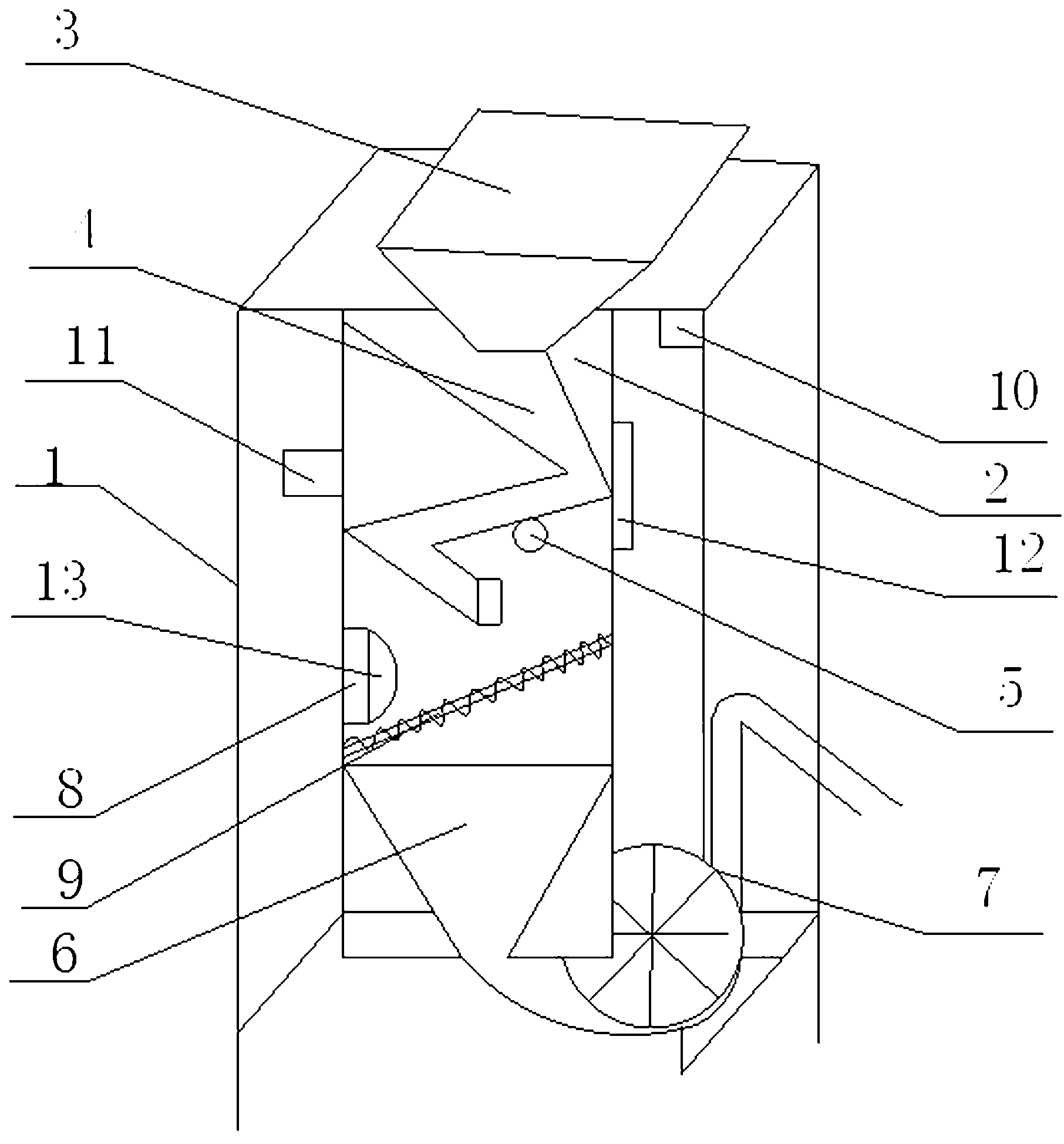

[0012] Such as figure 1 As shown, a bean drying device of the utility model includes a frame 1, an oven 2 is installed in the frame 1, a feeding hopper 3 is installed on the upper end of the frame 1, and a bean feeding hopper is arranged below the feeding hopper 3. A heater 5 is installed on the outer space of the channel 4 and the bean delivery channel 4, a discharge hopper 6 is arranged on the inner wall of the oven below the bean delivery channel 4, and a blower output channel 7, the bean delivery channel 4 and the discharge hopper are installed below the discharge hopper 6 The side wall of the oven between 6 is provided with an infrared heater 8, and the interior of the oven between the bean delivery channel 4 and the hopper 6 is also provided with a spiral roller 9. The heater 5 is connected to the power supply through a temperature adjustment switch 10, and the oven 2. A pressure relief valve 11 is provided on the outer wall, a thermometer 12 is provided outside the oven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap