All-bearing baffle plate device of dry type evaporator and using method

A technology of dry evaporator and baffle plate, which is applied in the direction of evaporator/condenser, heat exchanger shell, lighting and heating equipment, etc., can solve the problems of high processing cost, large support span, uneconomical, etc., and achieve Simple shape and structure, improved heat transfer performance, convenient production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

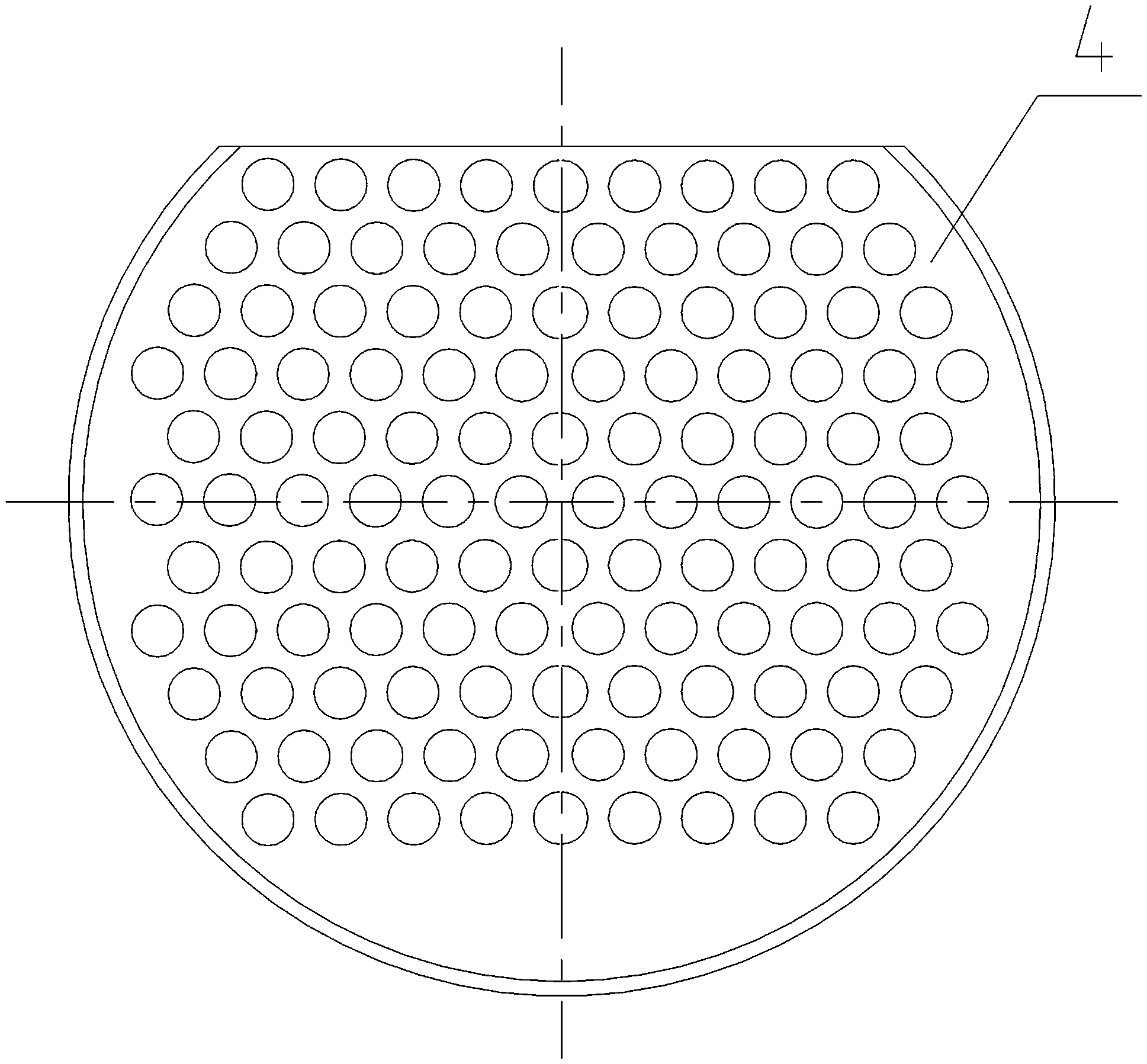

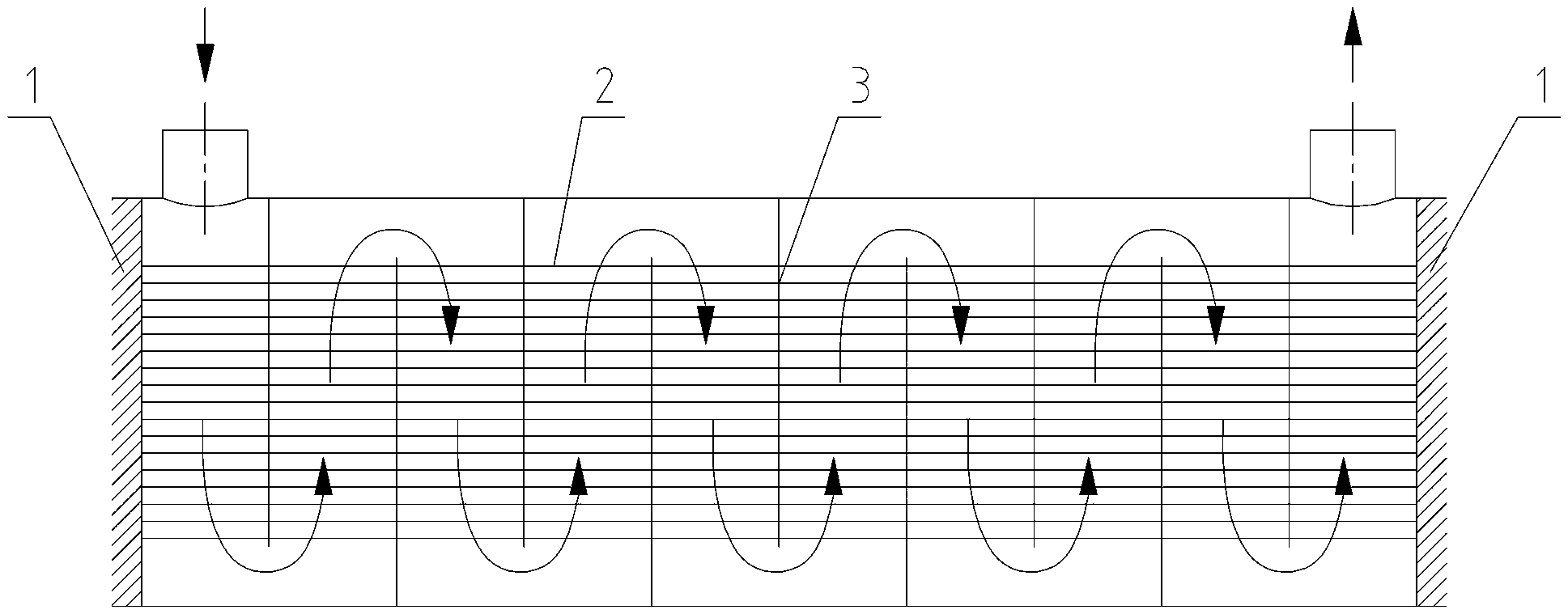

[0013] This embodiment is a dry-type evaporator fully supported baffle device used in the process of refrigeration and air conditioning with a cooling capacity of 930kW and a model of E2GZ0930H. It consists of a fully supported baffle 4 and associated tube sheets 1 and evaporator tube bundles 2, the full-support baffle 4 is a planar notched circular plate in the evaporator cylinder, its outer circle is Ф457mm with thin edges around it, so as to increase the fit with the evaporator cylinder, planar The thickness of the notched circular plate is 6mm, the thickness of the thin edge is 0.5mm, the width of the thin edge is 7mm, the notch height of the flat notched circular plate is 80mm, and the same number of tube holes as the tube plate is distributed on the planar notched circular plate. The diameter of the pipe hole is Ф13mm, and the related parts are as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com