Method for measuring straightness of super-long guide rail

A straightness and guide rail technology, which is applied to measuring devices, instruments, and optical devices, can solve problems such as low measurement accuracy, large errors, complex data processing and calculation, and achieve simple data processing, short test time, and data analysis. and the effect of simple experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

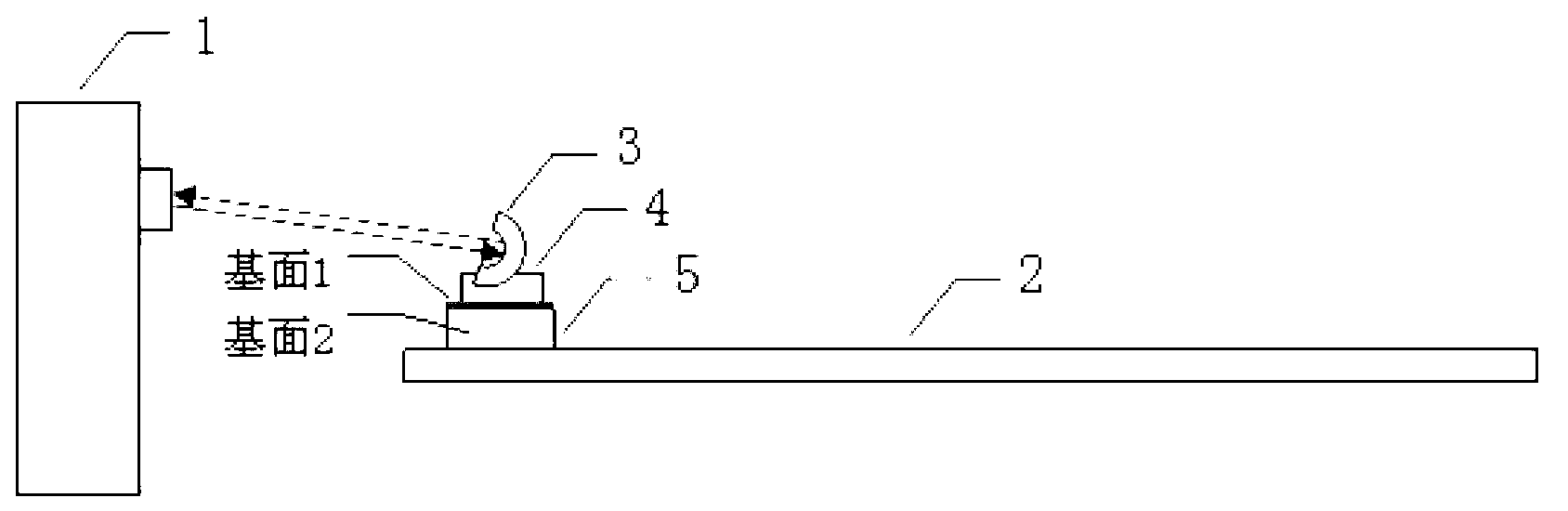

[0019] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, a method for measuring the straightness of an ultra-long guide rail, wherein the device involved in the method mainly includes a laser tracker 1, an ultra-long guide rail 2, a spherical fixed reflector 3, a reflector base 4, and a guide rail slide 5 ; The specific process of this method is:

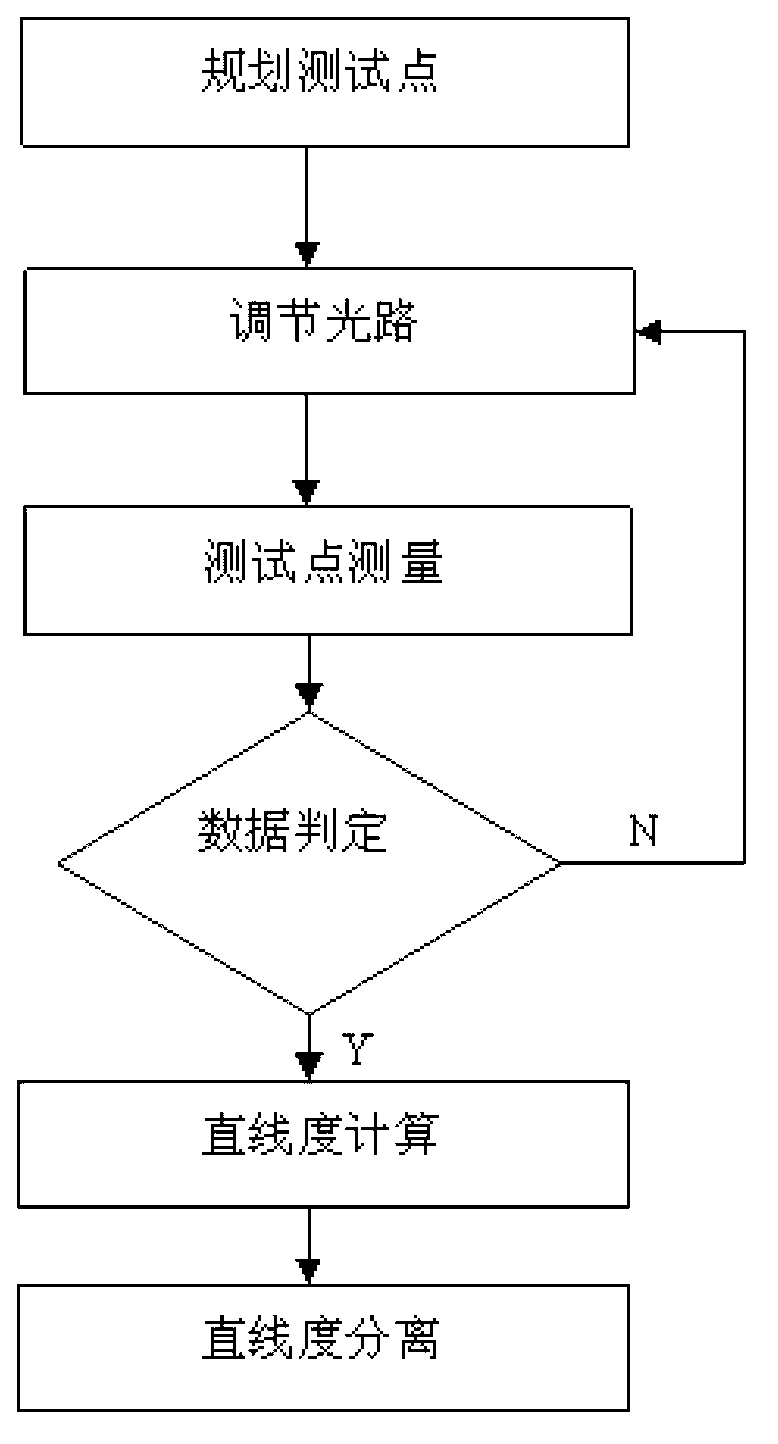

[0020] 1. Plan test points; plan several test sampling points on the super-long guide rail 2 at equal intervals;

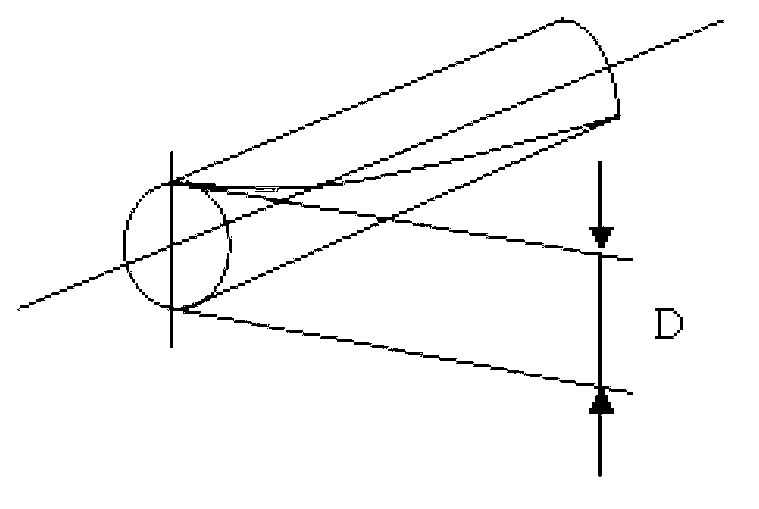

[0021] 2. Adjust the optical path; attach the reflector base 4 (magnetic) to the guide rail slide seat 5, and attach the spherical fixed reflector 3 to the reflector base 4. Due to the magnetic adsorption, the connection between the three is very After the connection is completed, adjust the optical path so that the laser tracker 1 is aligned with the first test point. Since the guide rail slide 5 is parallel to the super-long guide rail surface, measure the fluctuation of poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com