Pressure test clamp for efficient heat exchange tube

A technology for heat exchange tubes and pressure testing, which is applied in the direction of measuring the increase and decrease rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problems of increased detection workload, low applicable pressure, and low work efficiency , to achieve the effect of convenient and quick installation, reducing fixture specifications and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

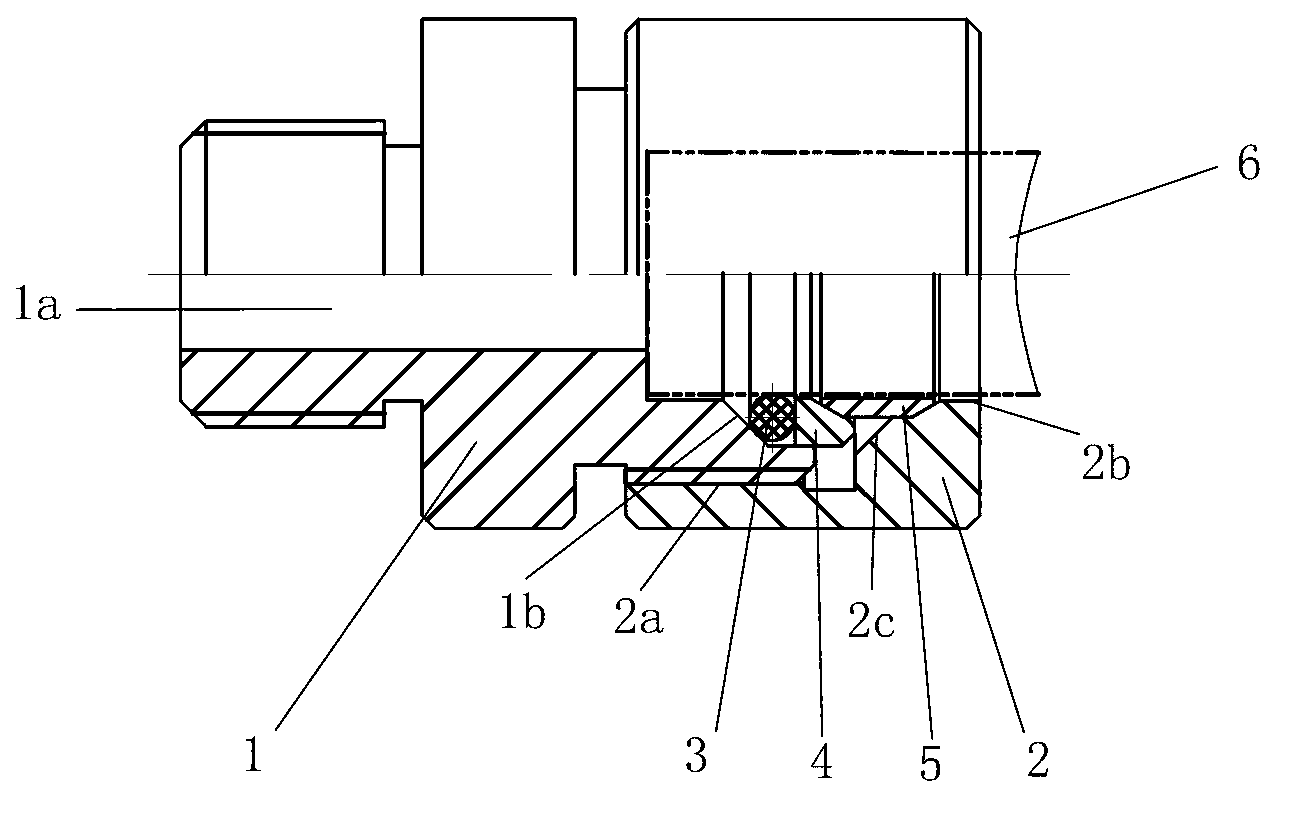

[0017] Such as figure 1 The high-efficiency heat exchange tube pressure test fixture shown is composed of a joint body 1, a lock nut 2, an O-ring 3, a conical sealing ferrule 4 and a conical locking ferrule 5, which are coaxially arranged.

[0018] The left and right ends of the joint body 1 have external threads, the external threads on the left end are used to connect high-pressure water pipes, and the external threads on the right end are used to connect lock nuts 2 . A stepped hole 1a penetrating left and right is provided in the joint body 1, the diameter of the left section of the stepped hole 1a is smaller than that of the right section, and a first inner tapered surface 1b is provided at the right end of the stepped hole 1a. There is a threaded hole 2a on the left part of the lock nut 2, which is used to connect with the joint body 1, the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com